Method for film coating by brush

A technology of brush and plating solution, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

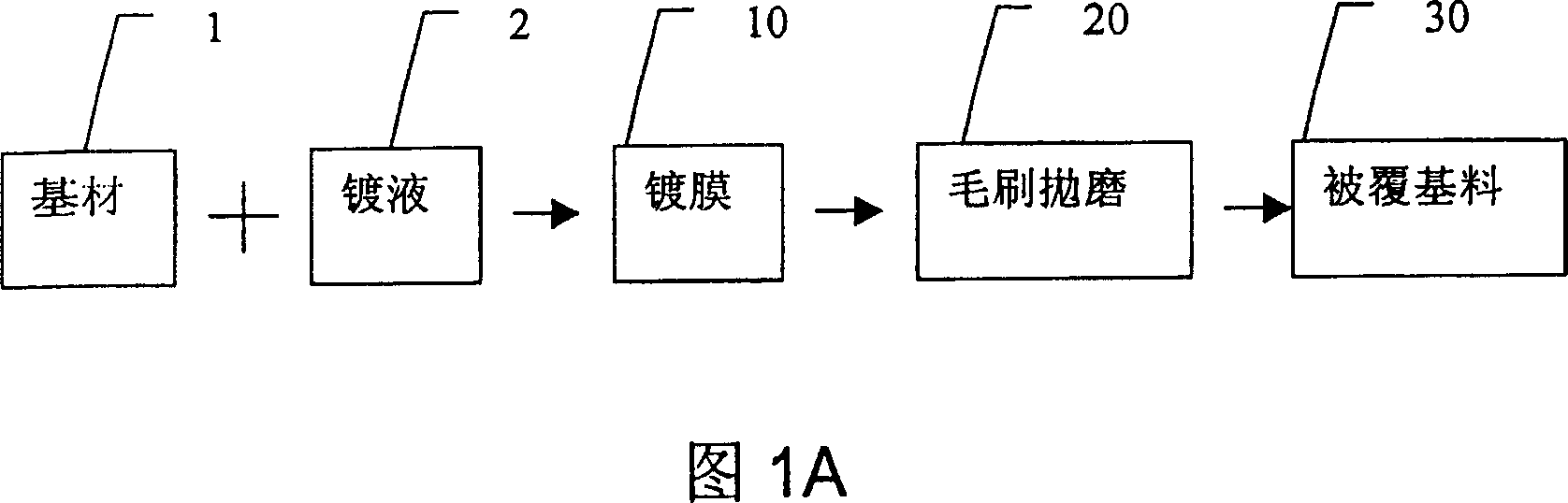

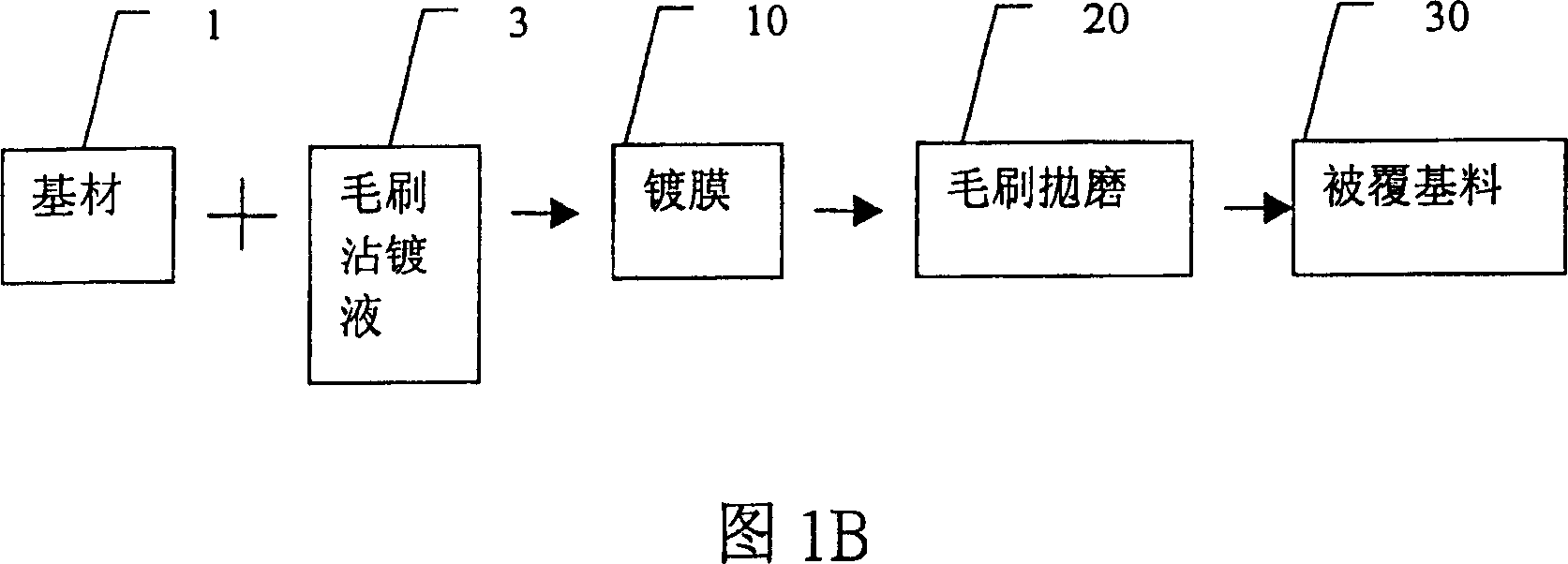

Method used

Image

Examples

Embodiment

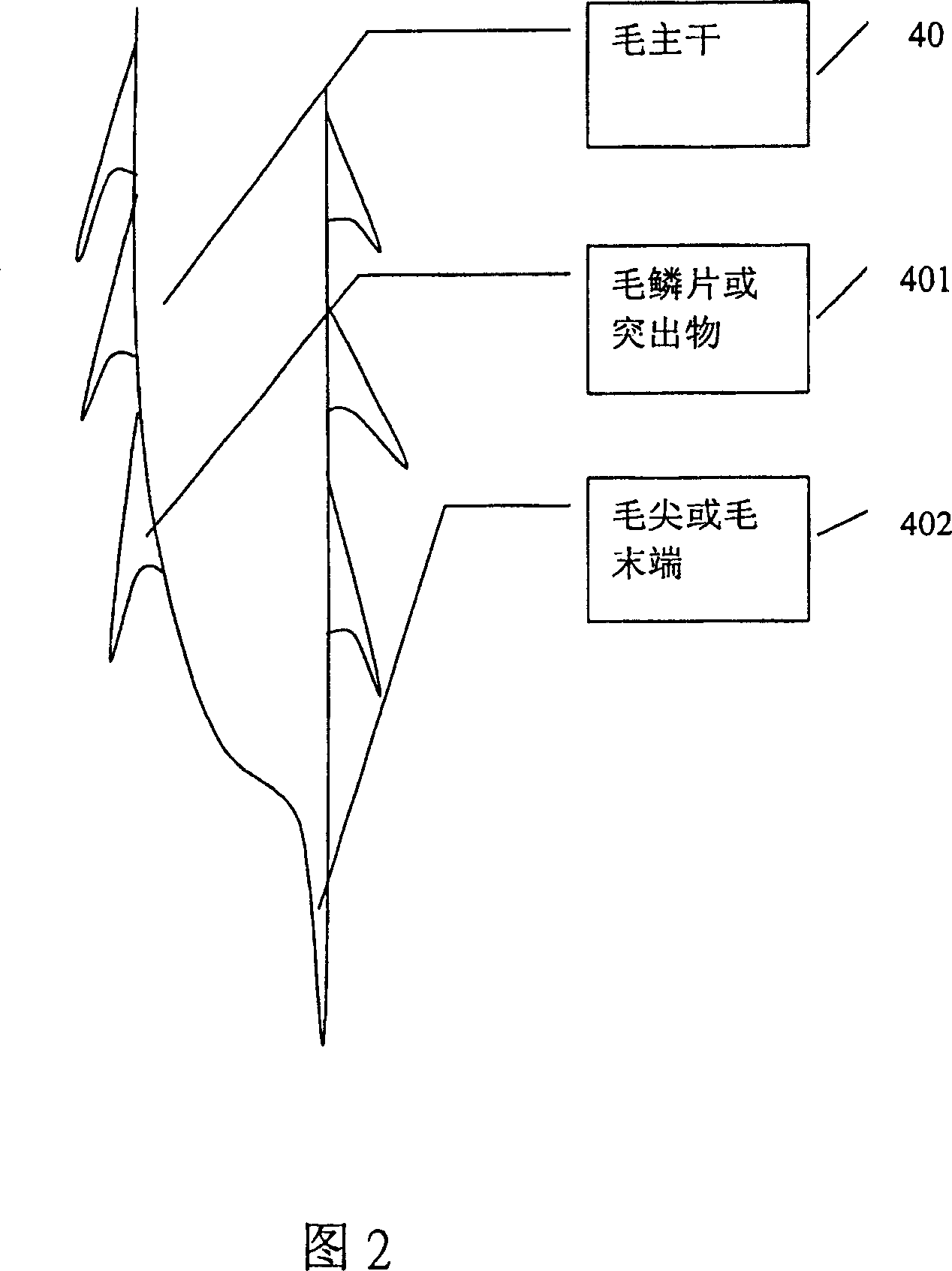

[0079] Trim the paint brushes available in the market, leave about 1.5cm and arrange them neatly, then tie them tightly with adhesive tape, and saw off the handle evenly, leaving only a wooden handle about 1.5cm high. At this time, the experiment The total height of the brush is 3cm for the brush plate (hereinafter referred to as the brush plate). Two groups of the same brush plate are made respectively, and one set is placed on the circular turntable of the manual car waxing machine (Nissan HITACHI). Fix the wool disc on it, and set the speed of the manual waxing machine at 1000 rpm (in the experiment, the speed was obtained from 200 to 1000 rpm, except for the forming speed, the results are the same, so no separate article is written), as Experiment 1.

[0080] The other brushes quickly left and right on the substrate manually, as Experiment 2.

[0081] Since the surface of fiber textiles also has similar hair scales or hair trunks that are attached separately or split from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com