Multi-stage rotary compressor

A technology of rotary compressors and compression units, applied in the field of compressors, can solve problems such as the inability to achieve different capacity changes, reduce compressor efficiency, and increase production costs, so as to improve reliability, improve efficiency, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

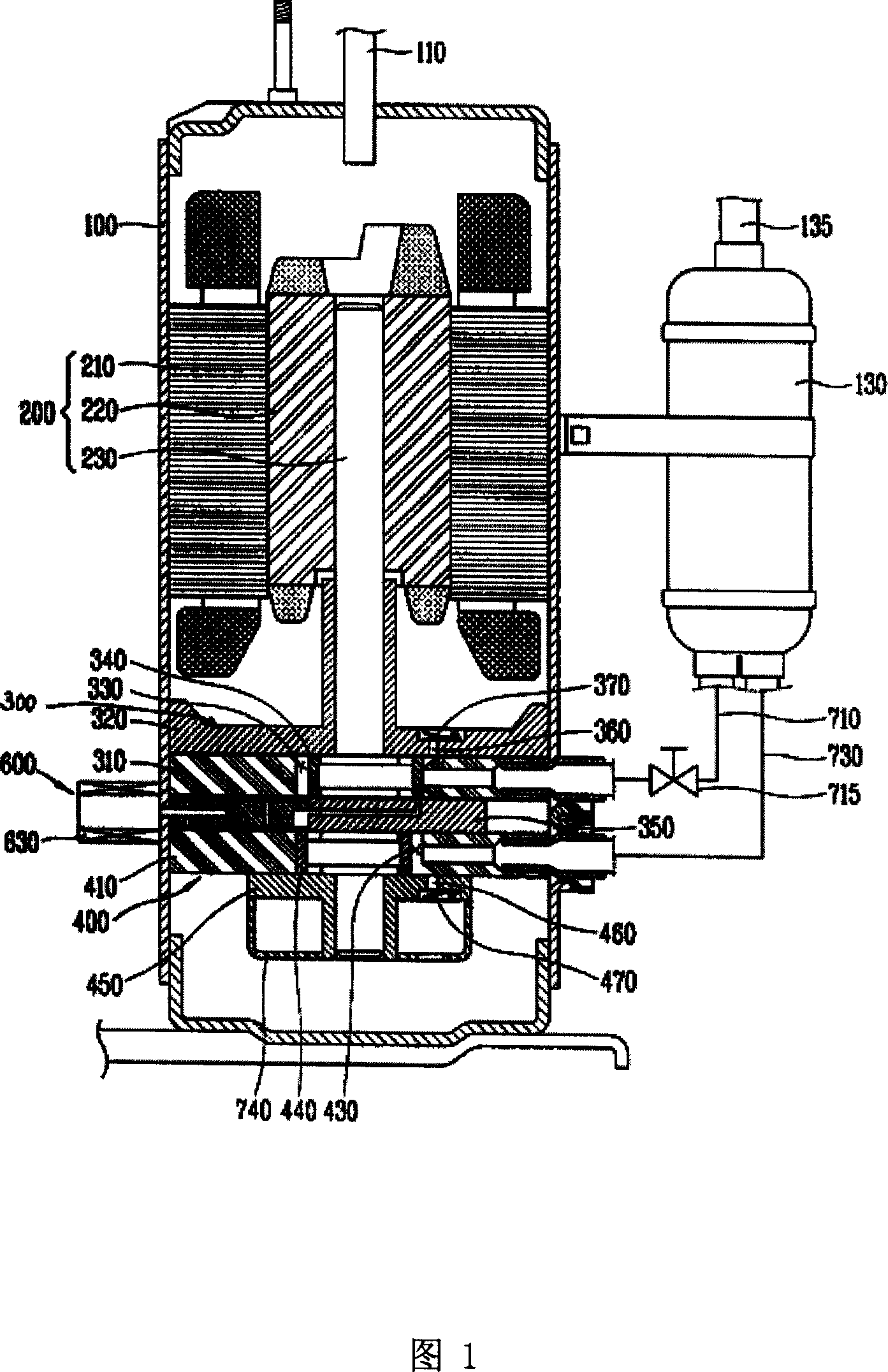

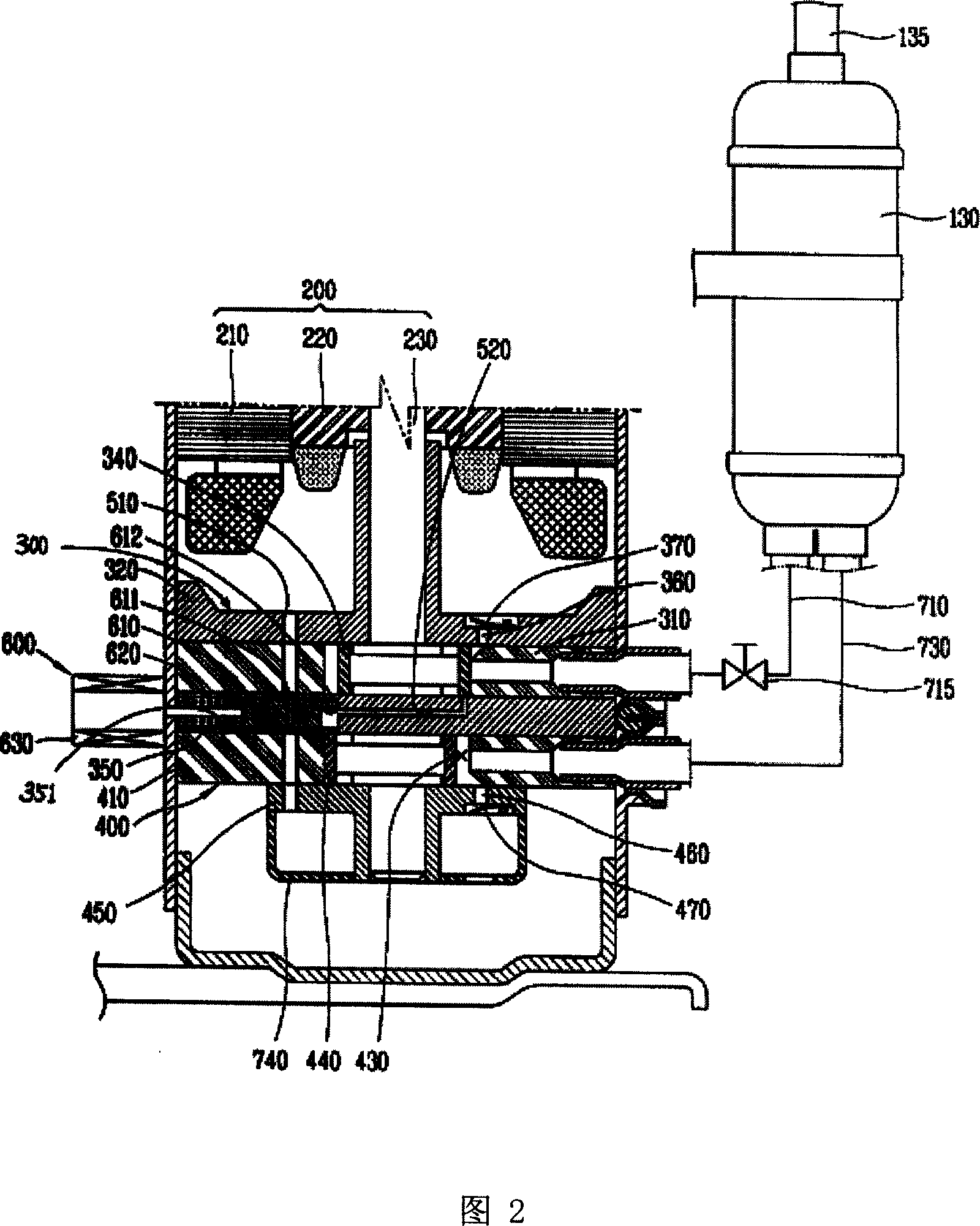

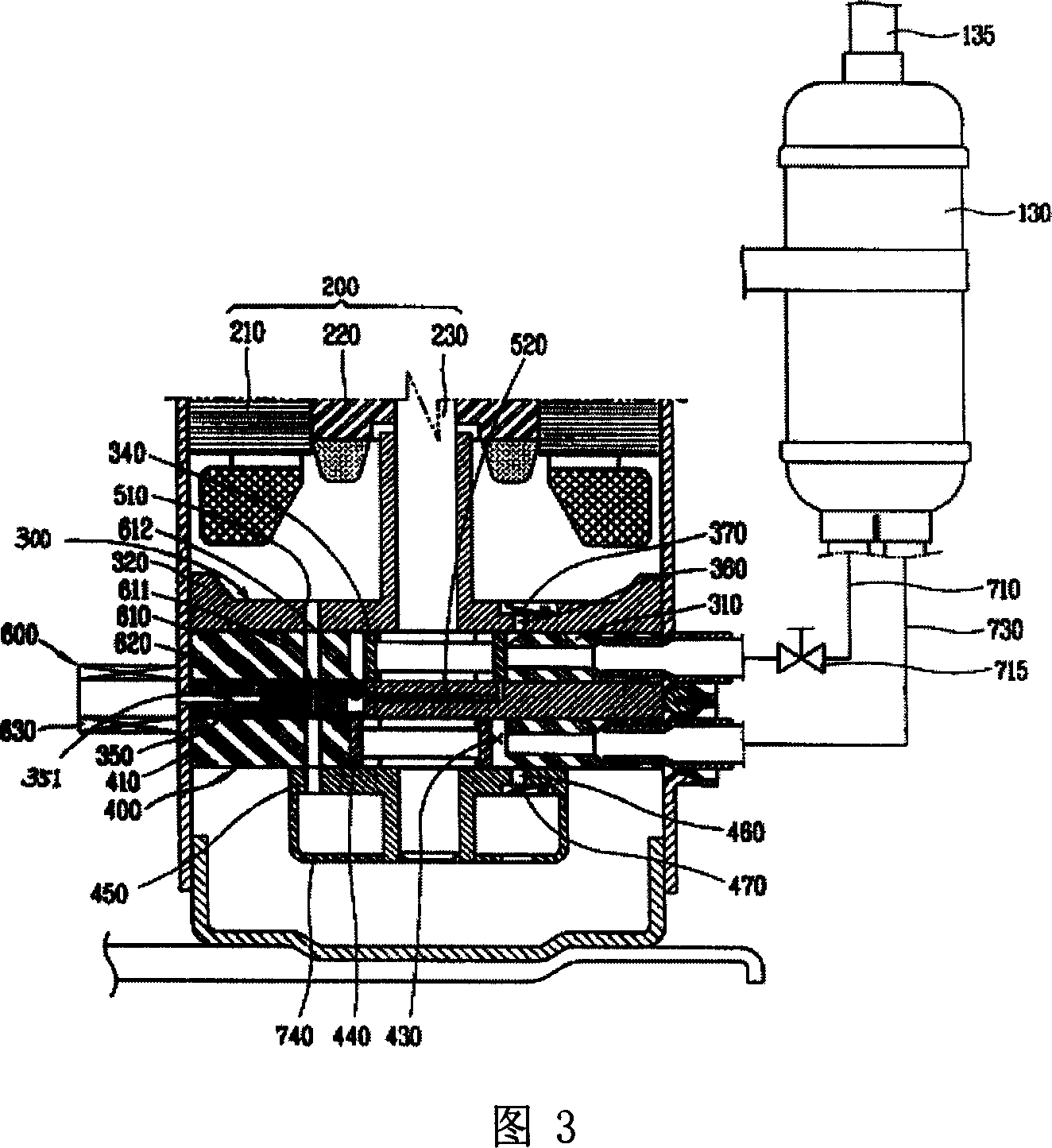

[0054] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail: Fig. 1 is the longitudinal sectional view of the 1st embodiment of the present invention, Fig. 2 is the enlarged sectional view of the main part of the 1st embodiment of the present invention; As shown, the multi-stage rotary compressor includes a casing 100 that forms a sealed control inside; a drive unit 200 installed in the casing 100 for generating driving force; and compressing the refrigerant by receiving the driving force transmitted by the drive unit 200 The first compression unit 300 and the second compression unit 400; the first suction pipe 710 leading the refrigerant to the first compression unit 300; the control valve 715 installed in the first suction pipe 710 for controlling the suction of refrigerant; Guide the refrigerant to the second suction pipe 730 in the second compression unit 400; temporarily store the refrigerant disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com