Spray paintable reflective single sided perspective film, and production method

A see-through film and reflective technology, used in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of short life, difficult to ensure the integrity of the film after punching, and difficult to ensure the installation effect is smooth and beautiful.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

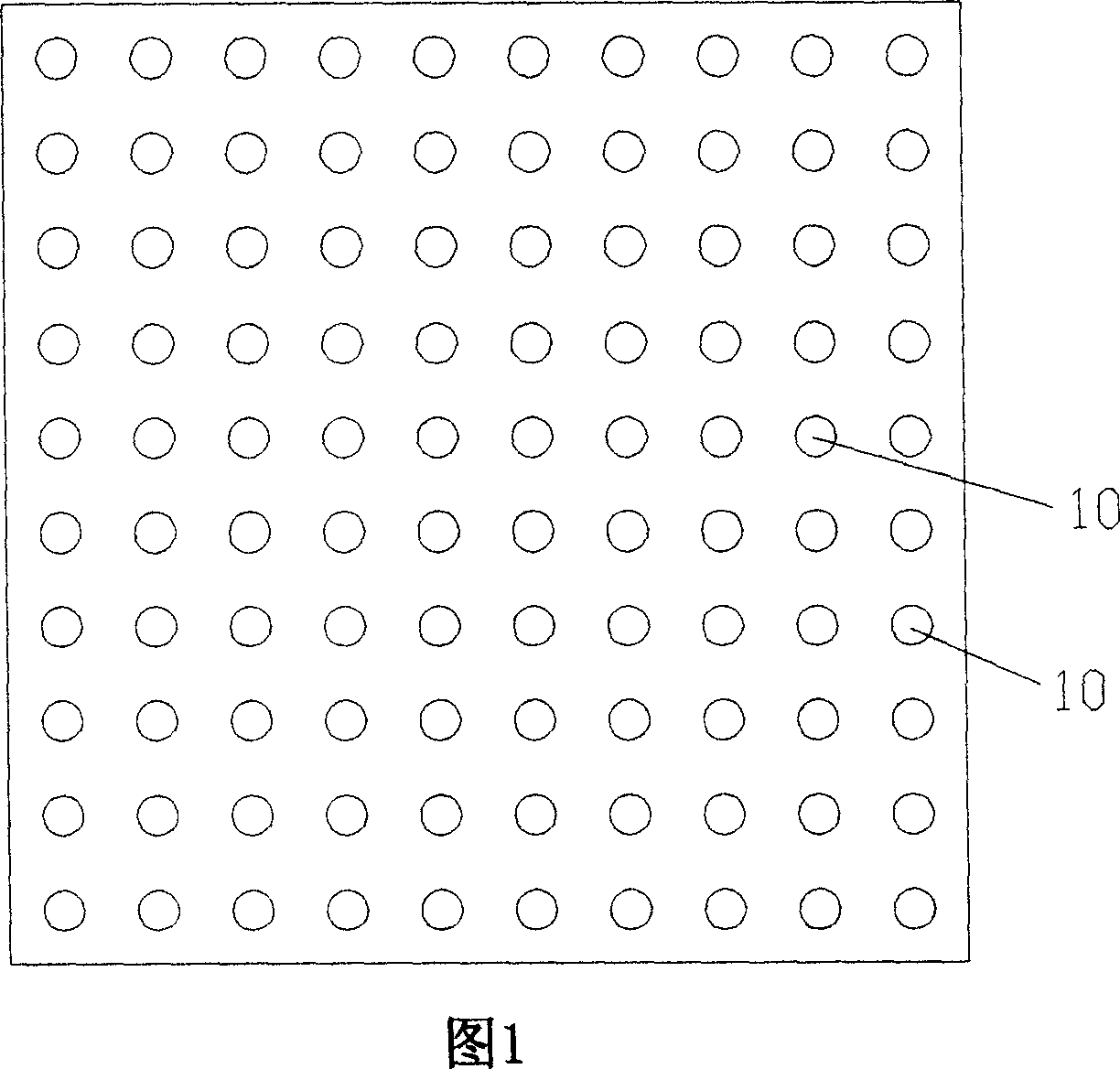

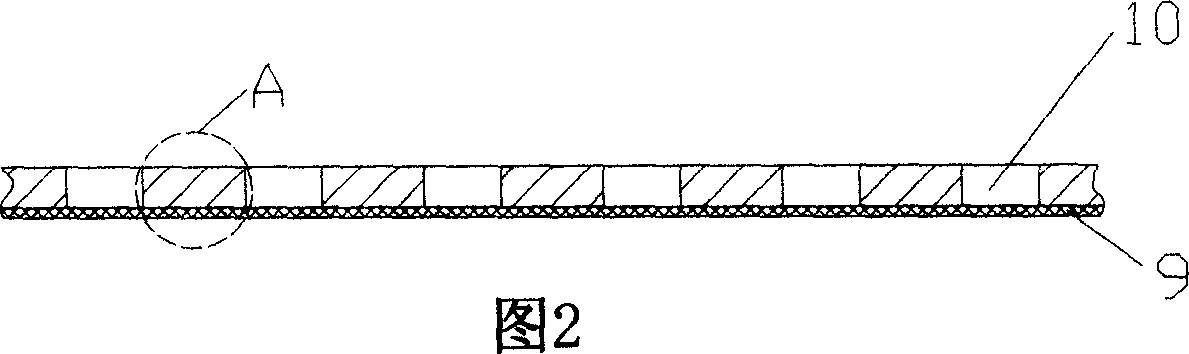

[0033] Using PET or acrylic as the carrier film, according to the conventional process, after the resin layer 3, the micro glass beads 4, and the reflective layer 5 are compounded, the lower layer of PVC 7 and the release paper layer are sequentially compounded on the outside of the reflective layer 5. Then peel off the PET or acrylic, compound and replace it with a colorable upper layer PVC 1, and then punch the resulting synthetic film with a hole diameter of 1.4-1.8mm, a hole distance of 1.8-2.6mm, and a hole density of 25-30 pcs / square centimeters. Finally, the punched release paper is peeled off, and the unpunched release paper 9 is combined to obtain a finished product, the structure of which is shown in Fig. 1 and Fig. 2 .

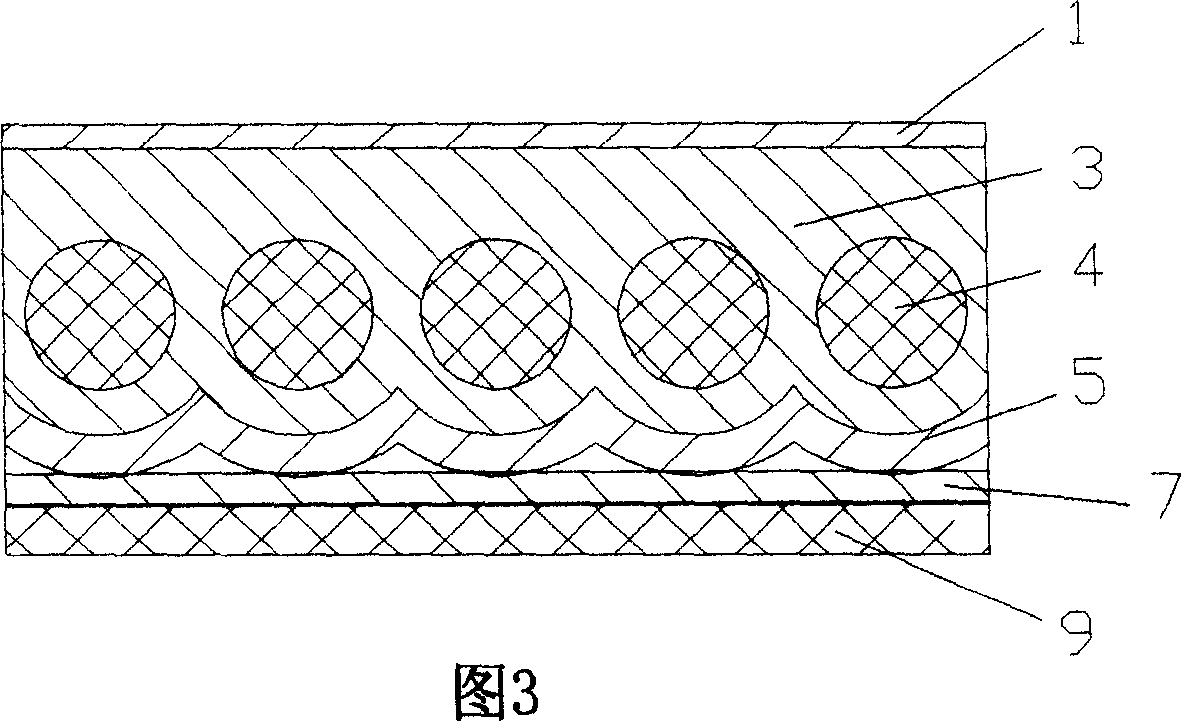

[0034] From Figure 3, the internal structure of the printable reflective single-sided see-through film can be observed. From top to bottom, there is a colorable upper layer PVC 1, a transparent resin layer 3, and glass beads 4 are distributed in th...

Embodiment 2

[0036] Using PET or acrylic as the carrier film, according to the conventional process, after compounding the resin layer 3, the micro glass beads 4, and the reflective layer 5, the colorable upper layer PVC 1 is compounded on the surface of the PET or acrylic carrier film 2; The outer side of the reflective layer 5 is sequentially compounded with the lower layer of PVC 7 and the release paper layer with an adhesive, and then the resulting synthetic film is punched with a hole diameter of 1.4-1.8mm, a hole distance of 1.8-2.6mm, and a hole density of 25- 30 / square centimeter; peel off the release paper through punching, compound the release paper 9 without punching to get finished product, its structure as shown in Figure 1 and Figure 2.

[0037] From Figure 4, it can be observed that the internal structure of the spray-paintable reflective single-sided see-through film includes, from top to bottom, a colorable upper layer PVC1, a PET or acrylic carrier film 2, a resin layer 3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com