Radiator

A technology of radiator and heat dissipation fin, applied in the direction of instruments, electric solid-state devices, semiconductor devices, etc., can solve the problems of inconvenience and trouble in production, and achieve the effect of stable fastening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

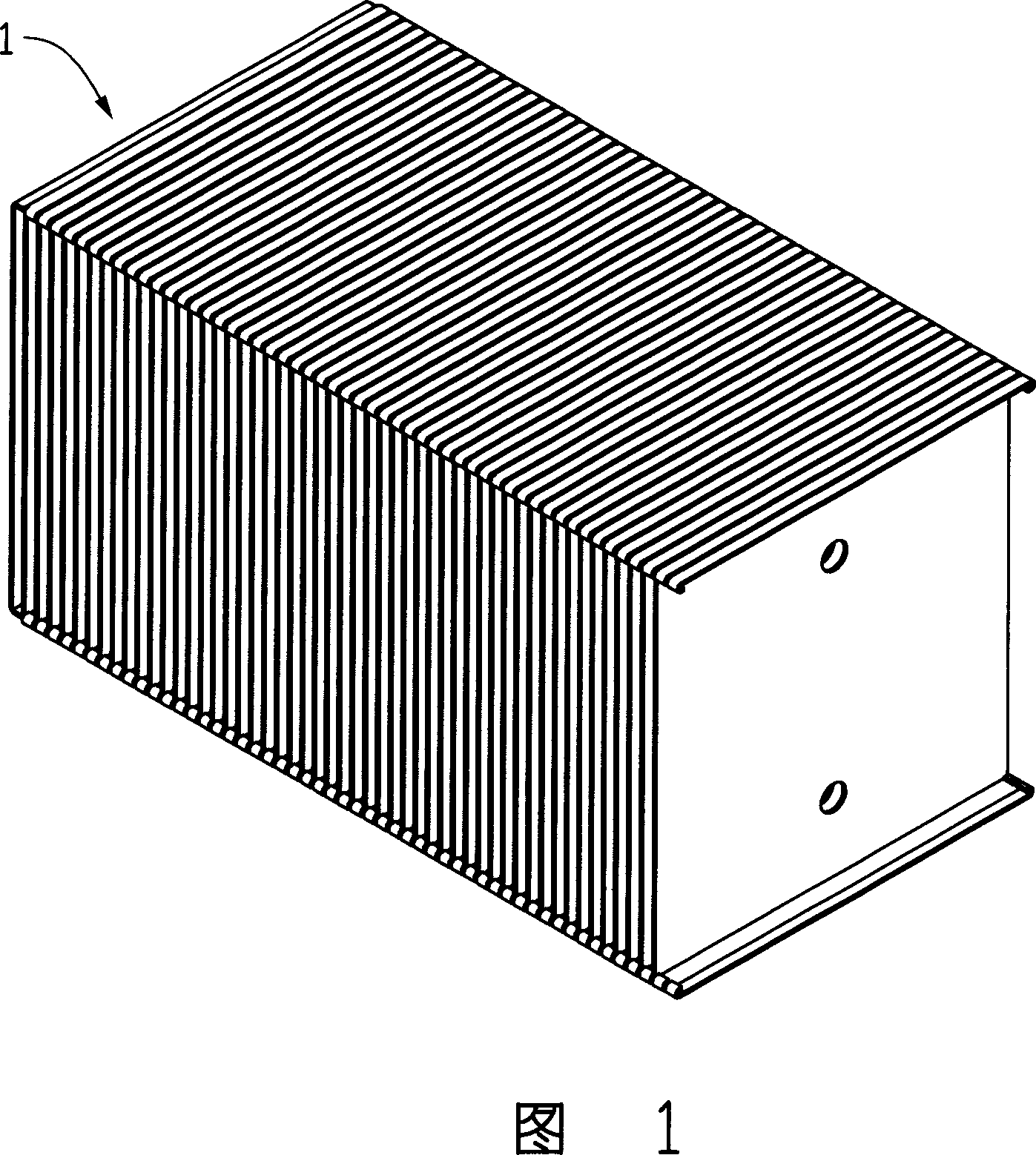

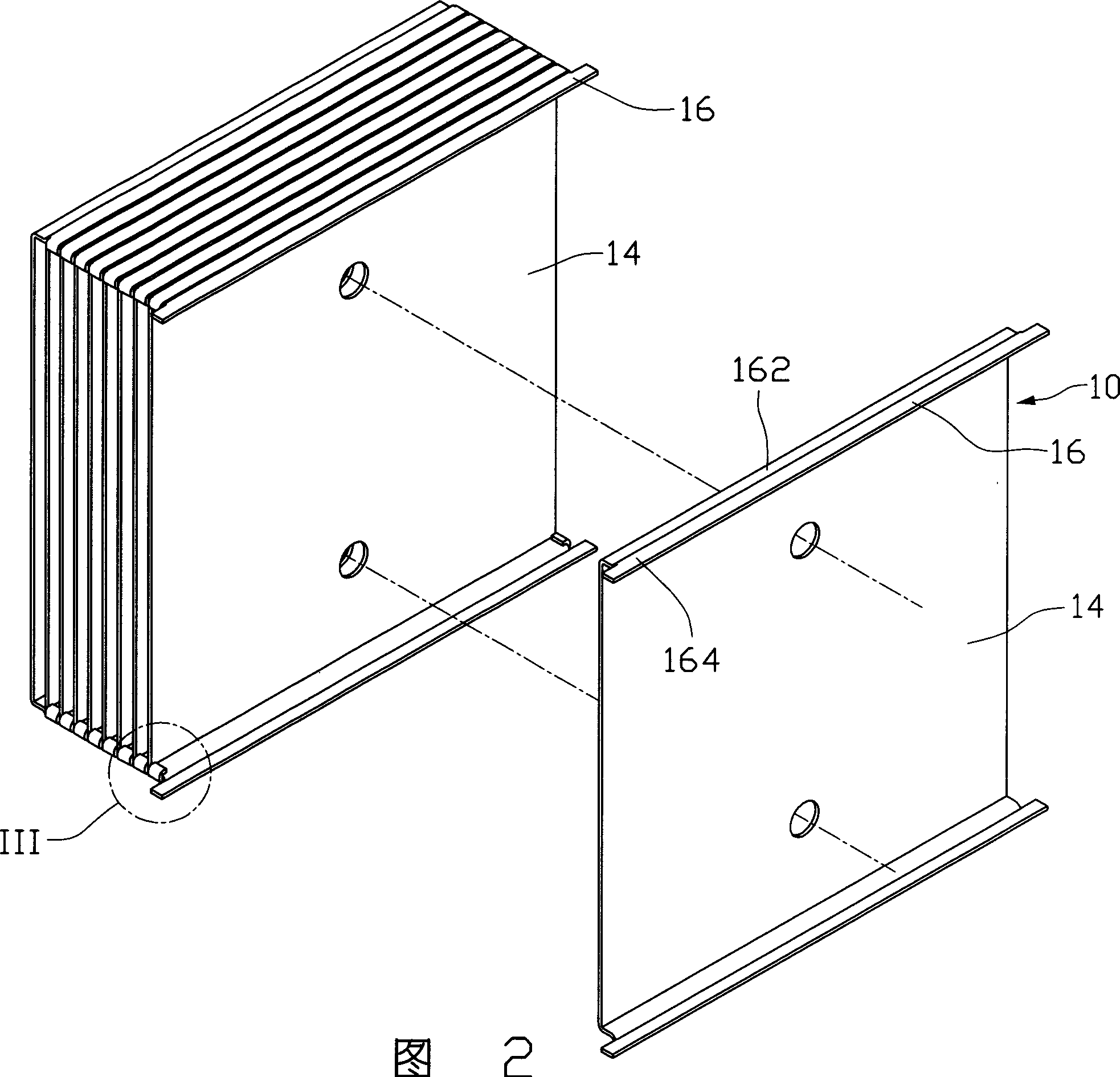

[0013] Please refer to Fig. 1 to Fig. 3, in the first embodiment of the present invention, the radiator 1 includes a plurality of heat dissipation fins 10 stacked on top of each other, the radiator 1 can be directly attached to the surface of the heating element (not shown), It can be pasted on a heat conduction plate (not shown in the figure), and then contact the heating element through the heat conduction plate.

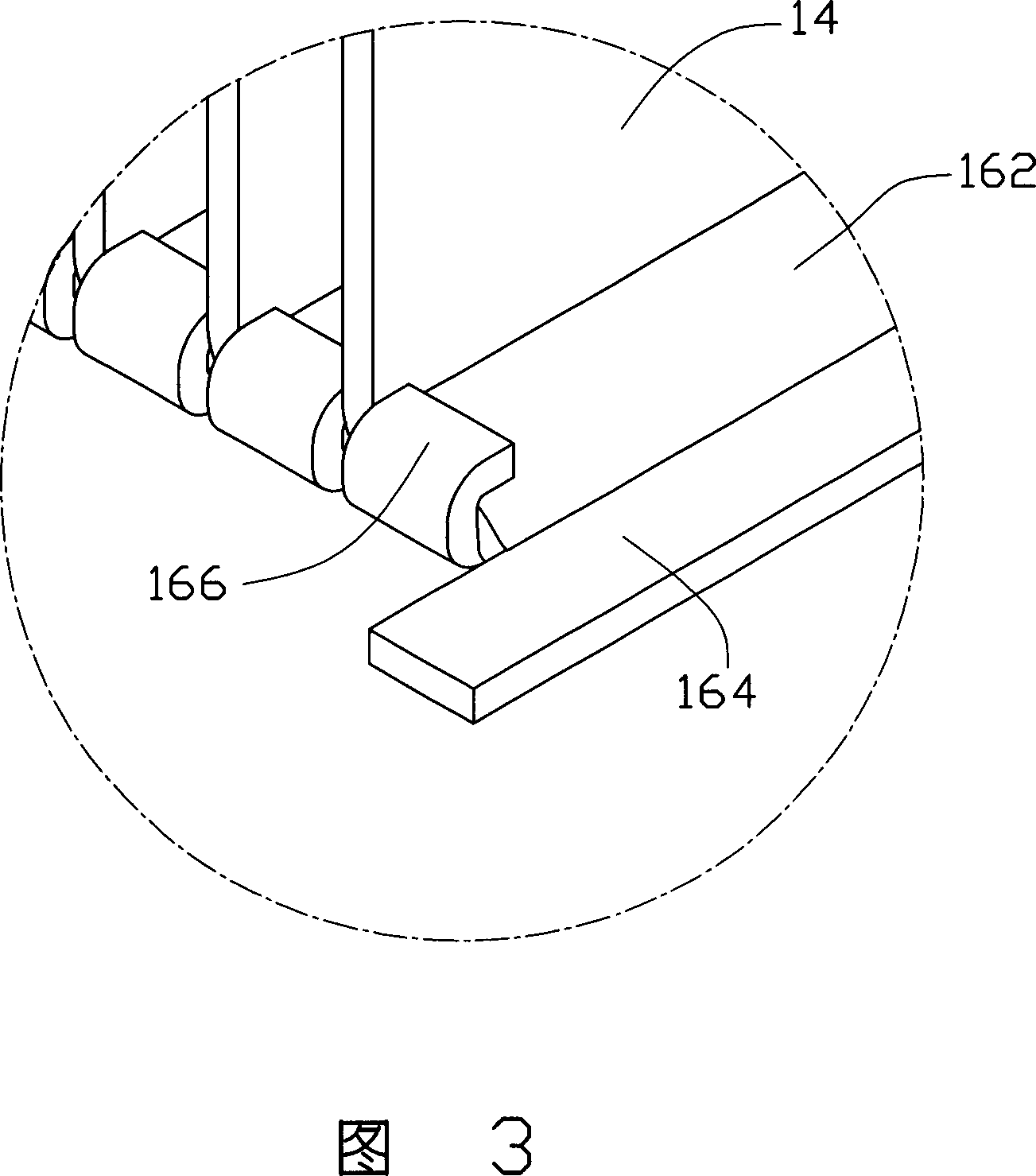

[0014] As shown in FIGS. 2 to 4 , each heat dissipation fin 10 has a flat heat dissipation body 14 , and the upper and lower edges of the body 14 are respectively bent and extended in the same direction with a folded edge 16 . Each flange 16 includes a receiving portion 162 extending along the edge of the main body 14 , a connecting portion 163 extending along the end of the receiving portion 162 , and a fastening portion extending from the free end of the connecting portion 163 parallel to the receiving portion 162 164. The connecting portion 163 is inclined to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com