Ink composition, method of ink-jet recording with the same, and recording object

An ink composition, composition technology, applied in the direction of copying/marking method, ink, application, etc., can solve problems such as uneven color balance, damage to image style, and reduce image quality, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11 and comparative example 1~8

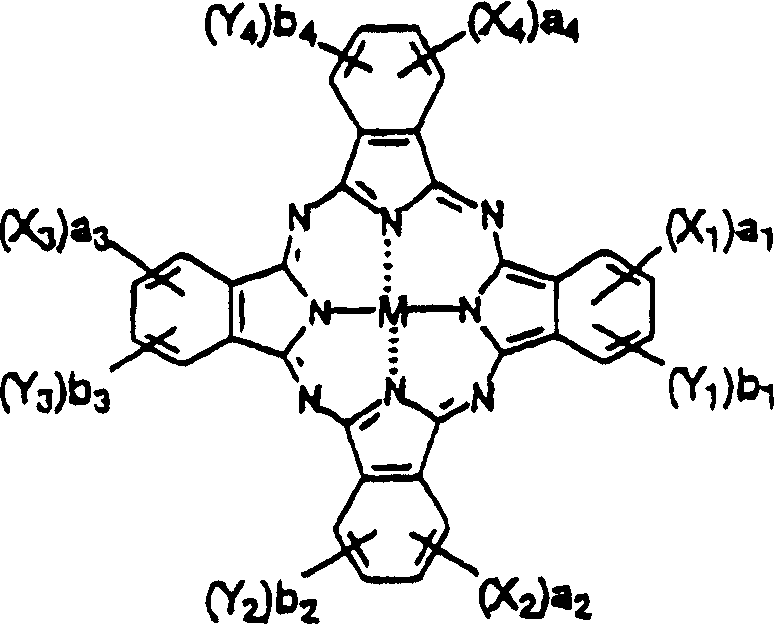

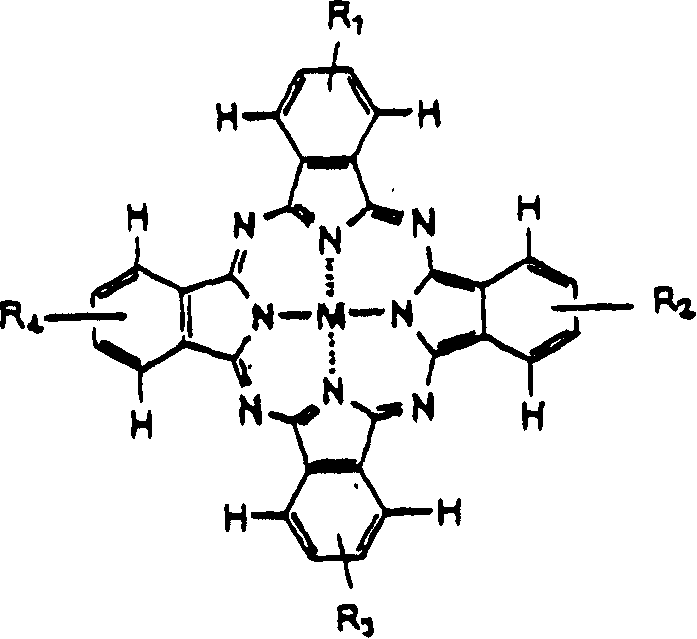

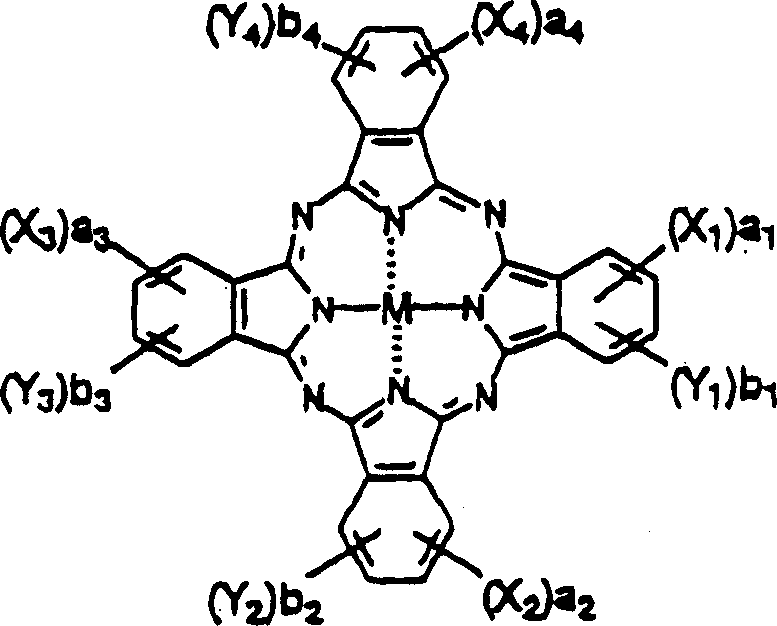

[0287] The components were mixed and dissolved in the compounding ratio shown in Table 9, and pressure filtration was performed through a membrane filter with a pore size of 1 μm to prepare the respective ink compositions of Examples 1 to 11 and Comparative Examples 1 to 8. Each component of the ink composition shown in Table 9 represents the weight % of each component relative to the total amount of the ink composition. In addition, M dye 1 in Table 9 is a compound represented by following formula (6).

[0288] Formula (6)

[0289] [chemical 15]

[0290]

[0291] (In formula (6), M represents NH 4 or Na, NH 4 :Na=1:1 (molar ratio). )

[0292] M dye 2 is a compound of dye 8 in Table 3, comparative dye 1 is C.I.Direct Red227, and comparative dye 2 is C.I.Acid Red 249.

[0293] The number of moles of Li and Na+K+NH in this combination 3 The number of moles of Li+Na+K+NH relative to the number of moles of carboxyl groups of 2-naphthoic acid 3 The molar ratio of Na+K+NH...

Embodiment 12~21 and comparative example 9~15

[0361] The components were mixed and dissolved in the compounding ratio shown in Table 14, and filtered under pressure with a membrane filter having a pore size of 1 μm to prepare the respective ink compositions of Examples 12 to 21 and Comparative Examples 9 to 15. Each component of the ink composition shown in Table 14 represents the weight % of each component relative to the total amount of the ink composition. It should be noted that, in the composition of Comparative Example 12, 2-naphthoic acid was not completely dissolved, and an ink composition usable for evaluation could not be obtained. In addition, in Comparative Example 13, the pH of the ink was 11.8, and there was a problem with the ink resistance of the printed part, so no evaluation was performed.

[0362] The number of moles of lithium ions and the number of moles of sodium ions + potassium ions to the number of moles of sulfoalkyl groups having ionic hydrophilic groups in the cyan dye in this composition, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com