Fuel supply device

A fuel supply device, fuel pump technology, applied in the direction of fuel injection devices, fuel injection pumps, charging systems, etc., can solve the problems of pipeline strength, installation size and similar limitations, complicated structure, and inability to guarantee, etc., to achieve Effects of weight reduction, power increase, and rise suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

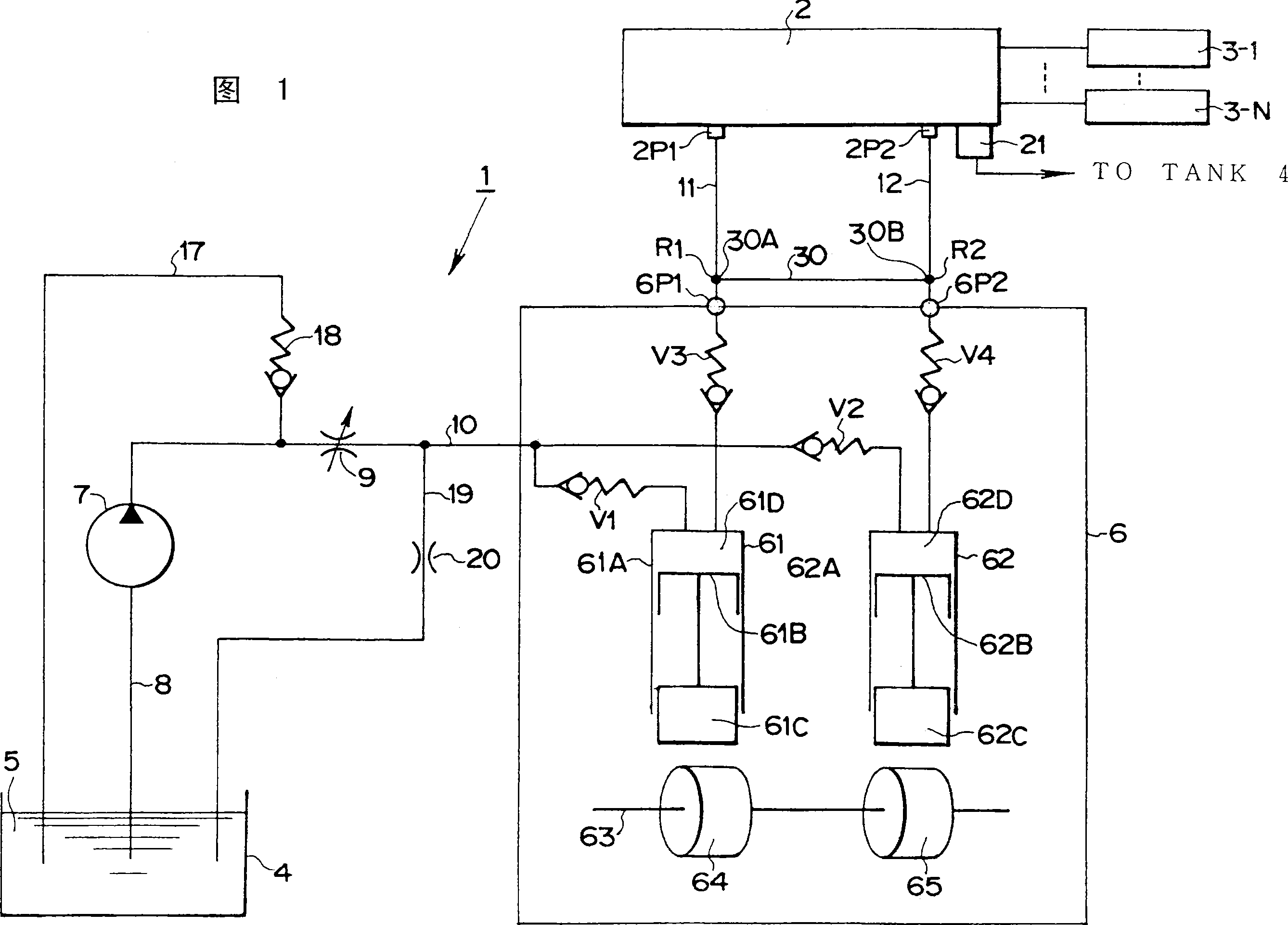

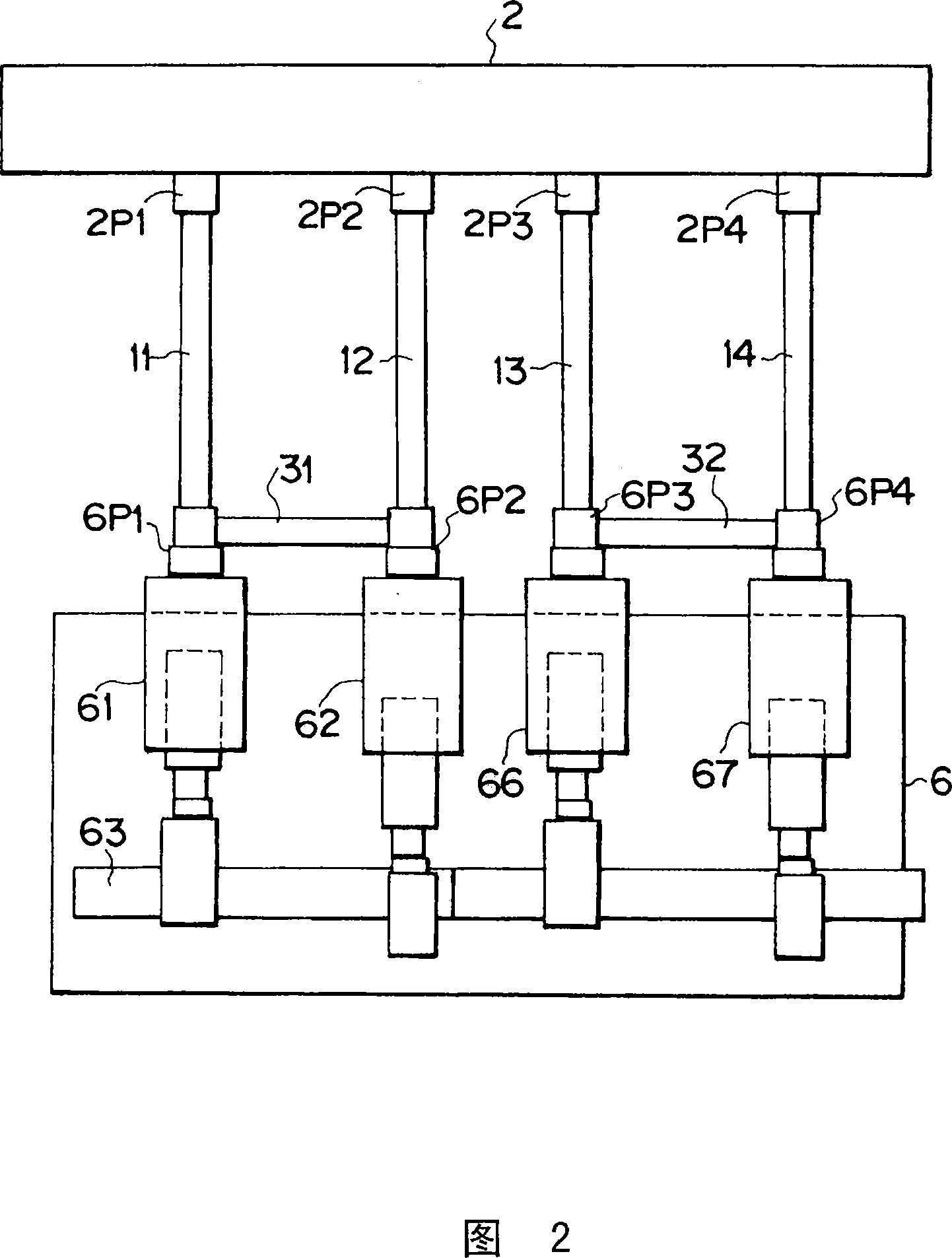

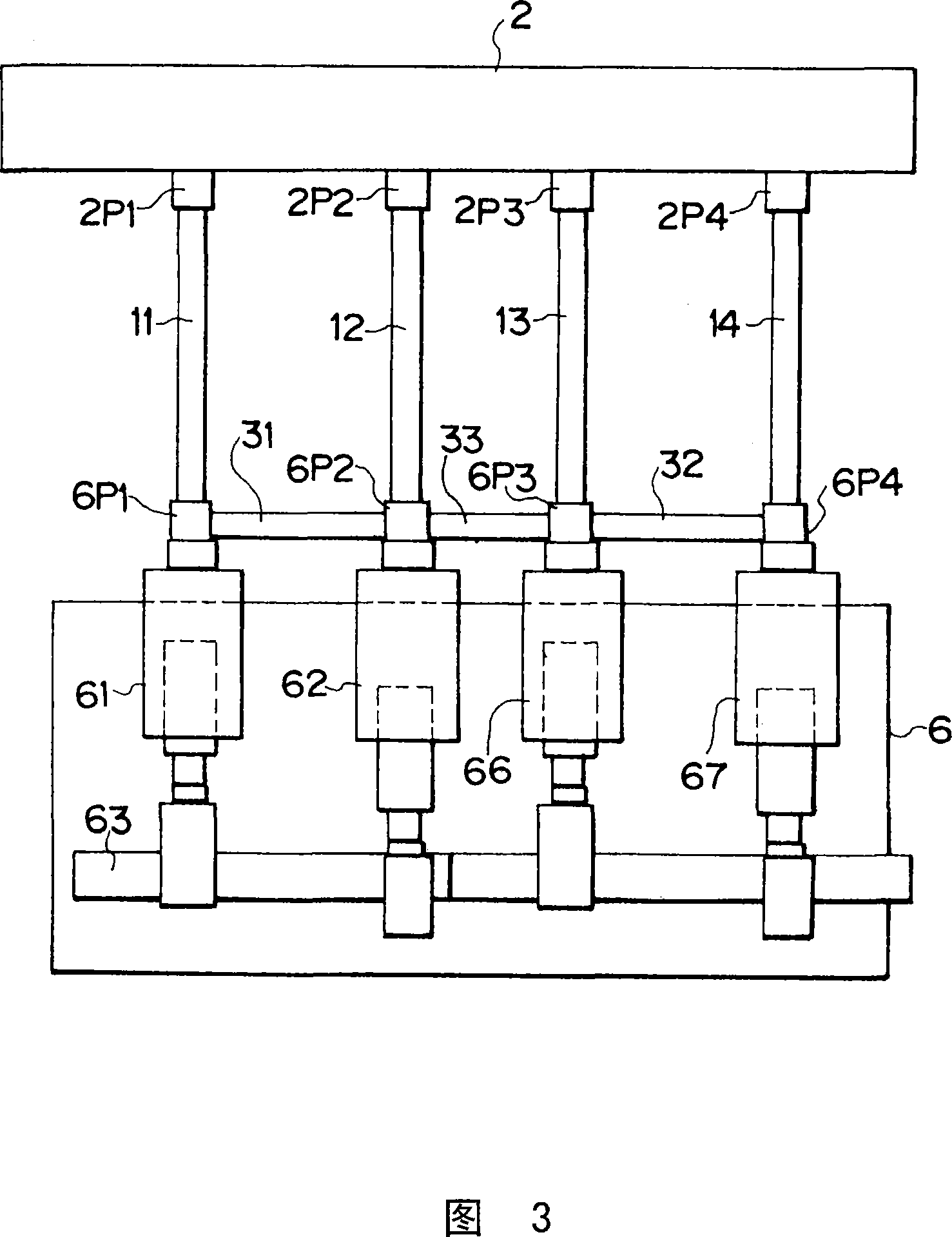

[0016] In order to describe the present invention in more detail, it is illustrated in conjunction with the accompanying drawings.

[0017] Fig. 1 is a structural schematic diagram of an embodiment of the present invention. The fuel supply device 1 shown in Fig. 1 is a common rail type fuel supply device, and high-pressure fuel is accumulated in its common rail 2, and the high-pressure fuel is injected and supplied to each cylinder of the internal combustion engine through injectors 3-1~3-N (Fig. not shown). The common rail 2 has a pressure control valve 21 to adjust the fuel pressure inside the common rail 2 to a desired value. Each cylinder is respectively equipped with injectors 3-1-3-N, and is subject to on / off control of an injection control unit composed of a microcomputer (not shown in the figure).

[0018] In FIG. 1, reference numeral 4 designates a container for accumulating fuel 5, reference numeral 6 designates a fuel pump (feed pump), and reference numeral 7 desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com