Use method of industrial caustic dross in treatment of road bed and foundation

An application method and grass-roots treatment technology, applied in the direction of roads, roads, buildings, etc., can solve problems such as hindering urban development, occupying land, and having a large impact on the urban environment, so as to reduce the pressure on land resources, reduce project costs, and eliminate pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

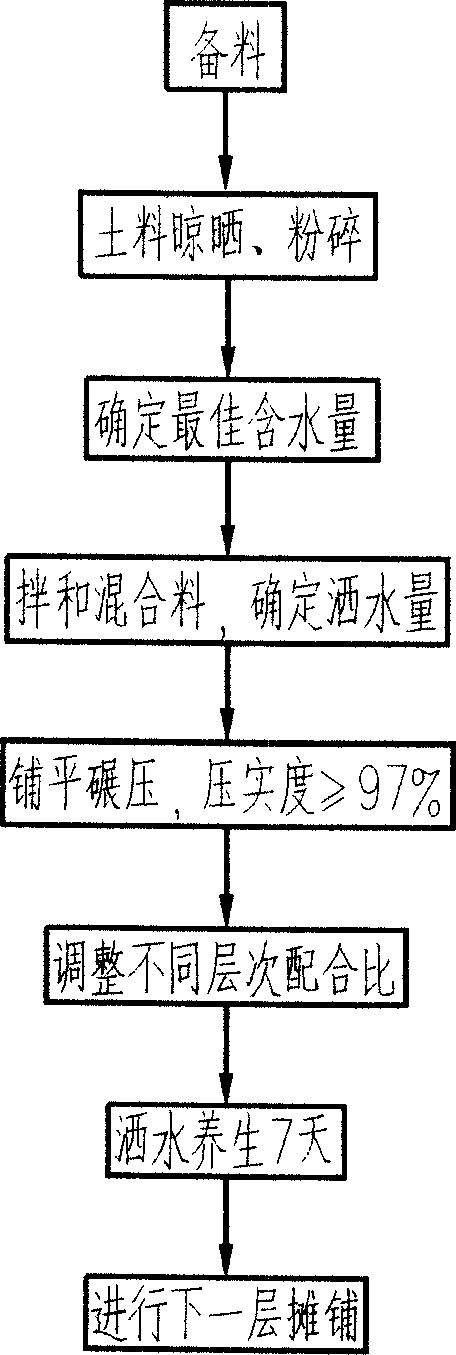

Embodiment 1

[0021] Prepare materials, including alkali slag, brick slag, fly ash, cement or lime, and soil; dry and crush the alkali slag and site soil; then, through indoor heavy-duty compaction tests, determine the optimum water content of the mixture to be 17-24 %, the maximum dry density is 1.79~2.08×10 3 kg / m 3 ; prepare the shallow treatment lower layer soil, its composition includes by weight percentage: 31% alkali slag, 65% soil, 4% lime; prepare shallow treatment upper layer soil, its composition includes by weight percentage: 30% Soda slag, 63% of soil, 4% of lime, 3% of cement; prepare subbase and base course, and its composition includes: 30% of soda slag, 10% of cement, 30% of fly ash in weight percentage , 30% brick slag, mix each layer of soil evenly according to the determined ratio, measure the natural water content to be 14.2-19%, and determine the spraying water amount to be 53.2-95kg according to the difference between the optimum water content and the natural water c...

Embodiment 2

[0023] Prepare materials, including alkali slag, brick slag, fly ash, cement or lime, and soil; dry and crush the alkali slag and site soil; then, through indoor heavy-duty compaction tests, determine the optimum water content of the mixture to be 18-22 %, the maximum dry density is 1.75~1.96×10 3 kg / m 3 ; prepare the shallow treatment lower layer soil, its composition includes by weight percentage: 40% alkali slag, 55% soil, 5% lime; prepare shallow treatment upper layer soil, its composition includes by weight percentage: 38% Soda slag, 55% of soil, 5% of lime, 2% of cement; prepare the base course and base course, and its composition includes: 42% of soda slag, 8% of cement, 25% of fly ash in weight percentage , 25% brick slag, mix each layer of soil evenly according to the determined ratio, measure the natural water content to be 15.6-19.8%, and determine the spraying water amount to be 41.8-45.6% based on the difference between the optimum water content and the natural w...

Embodiment 3

[0025] Prepare materials, including alkali slag, brick slag, fly ash, cement or lime, and soil; dry and crush the alkali slag and site soil; then, through indoor heavy-duty compaction tests, determine the optimum water content of the mixture to be 17-22 %, the maximum dry density is 1.73~1.98×10 3 kg / m 3 ; Prepare shallow subsoil, its composition includes: 45% alkali slag, 50% soil, 5% lime in weight percentage; Prepare shallow upper layer soil, its composition includes in weight percentage: 45% alkali slag , 45% of soil, 8% of lime, 2% of cement; prepare subbase, base, its composition comprises respectively by weight percentage: 35% of alkali slag, 5% of cement, 25% of fly ash, 35% % of brick slag, mix each layer of soil according to the determined ratio, measure the natural water content as 14.8-19.1%, and determine the spraying water amount as 41.8-55.1kg / m 3 , to make it reach the optimum water content; pave and roll on site, control the compaction degree of the shallo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com