Buckling-restrained brace of combined hot-rolled angle steel

An angle steel and anti-pressure technology, which is applied in the direction of earthquake resistance, building components, building structures, etc., can solve problems such as the cross-sectional shape of steel cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

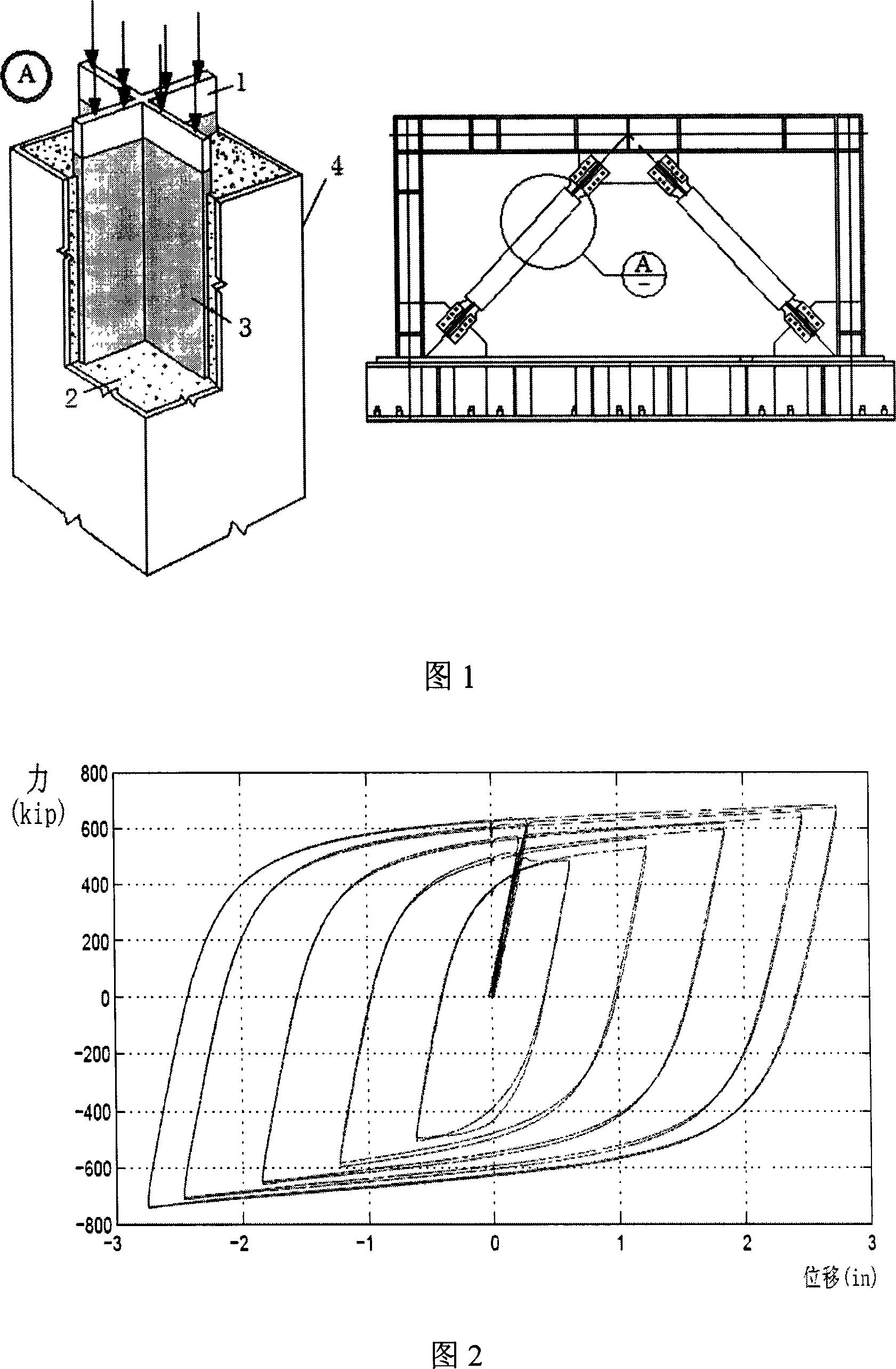

[0066] A four-story steel frame structure with a construction area of about 5000m 2 , the height of the first floor is 4.8m, the standard floor height is 4.2m, and the total height of the structure is 17.4m. The laminated floor of profiled steel plate is adopted, and the live load of the floor is 2.5kN / m 2 . The seismic fortification intensity is 8 degrees, the basic seismic acceleration of the structure is 0.2g, and the site is class II. The design earthquake is grouped into the first group.

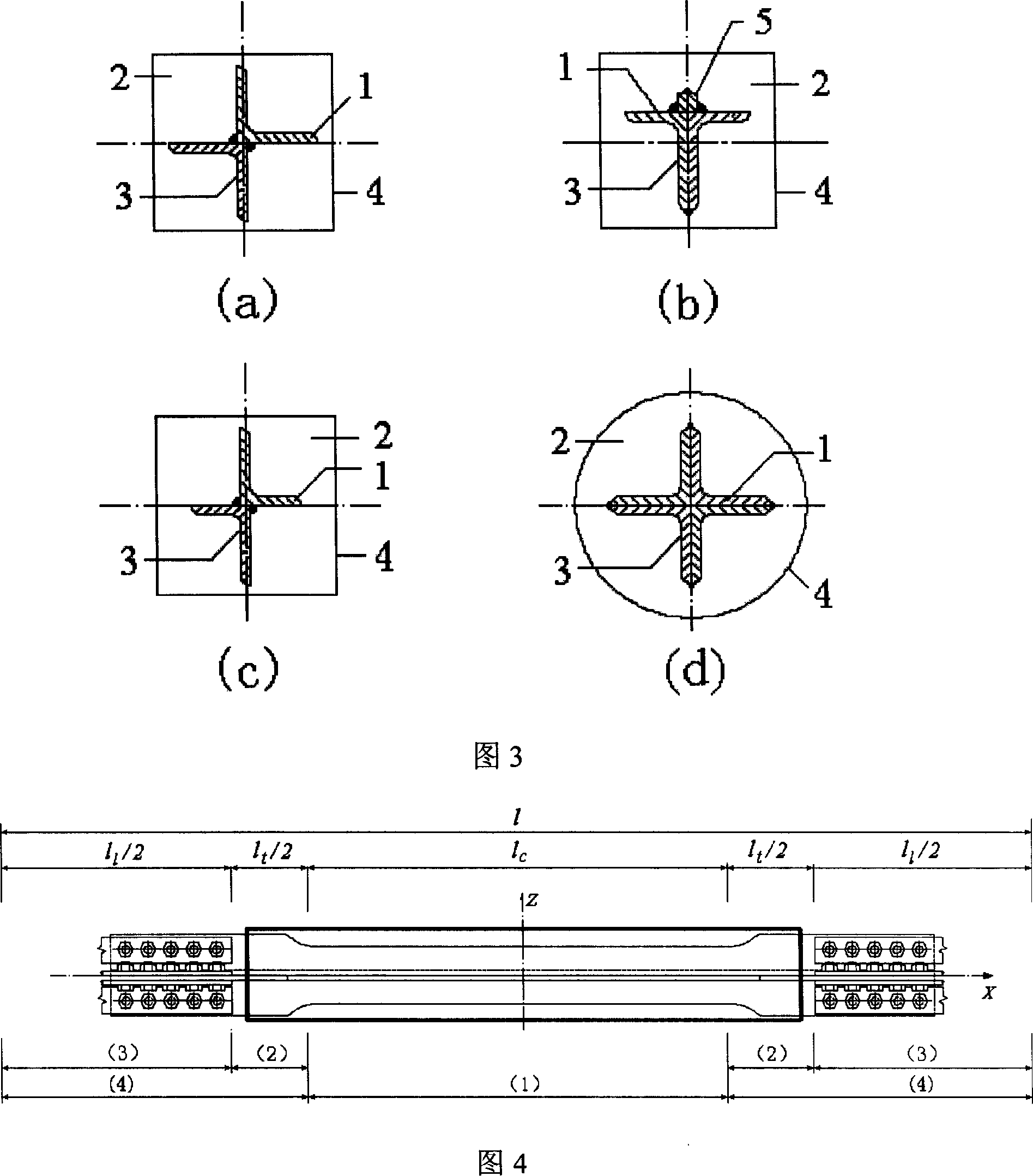

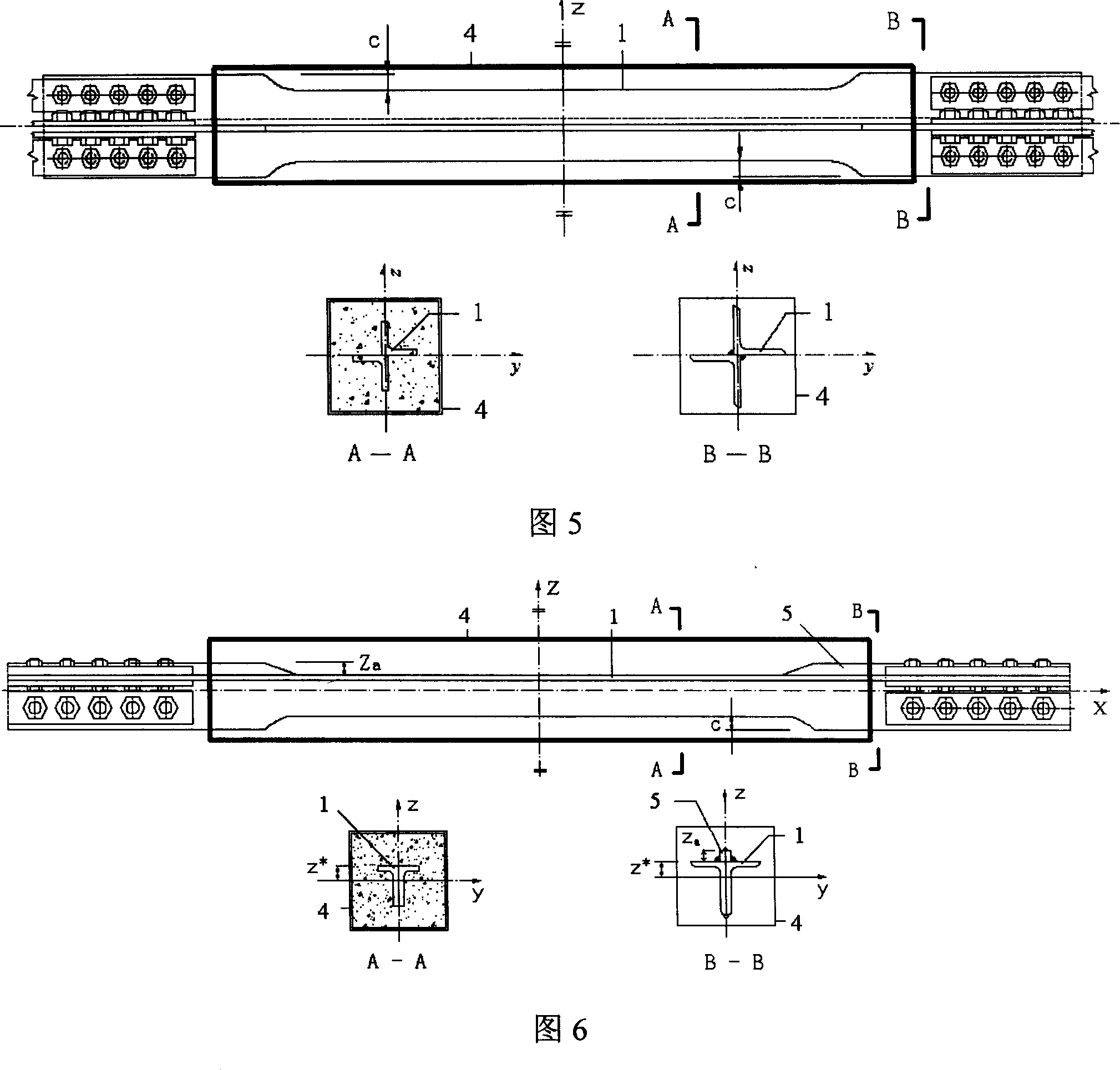

[0067] 1. Selection of steel frame structure and design and manufacture of combined hot-rolled angle steel anti-buckling support

[0068] 1) Type selection of the main steel frame structure and lateral stiffness of the anti-buckling support: determine the column grid size of the main frame structure according to the building function requirements, and determine the vertical load bearing capacity according to the "Code for Design of Steel Structures" (GB50017-2003) and vertical disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com