Tension-pressure equal-strength type metal energy consumption re-centering damper and installation and using method thereof

A self-resetting and damper technology, which is applied in the direction of shock absorbers, shock absorbers, building types, etc., can solve the problems of unstable energy consumption, easy leakage, and reduced friction, and achieve stable energy consumption , Energy consumption mechanism is clear, the effect of high carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

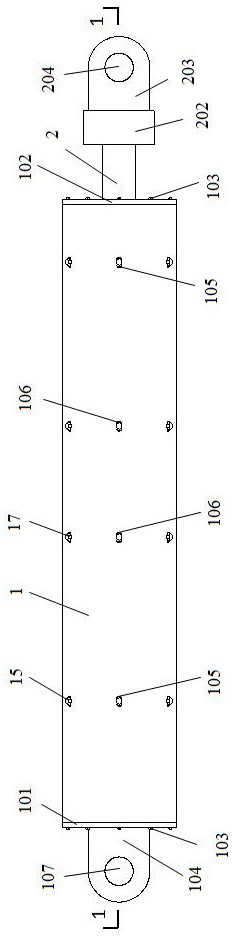

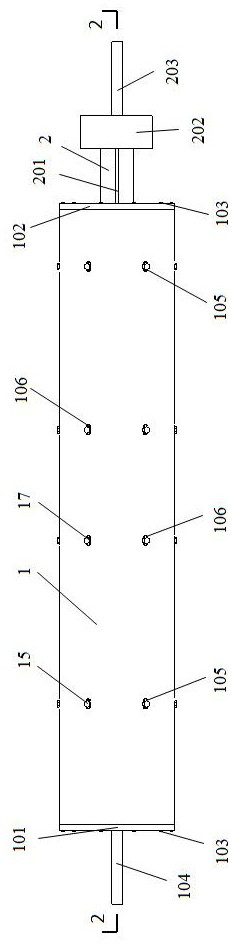

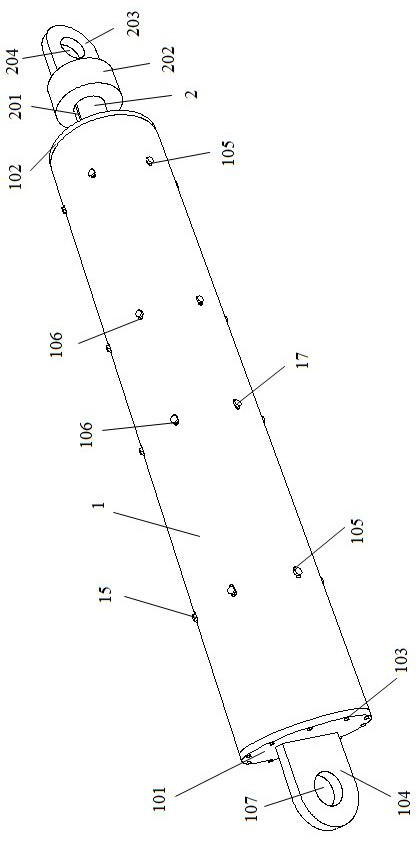

[0036] A tension-compression equal-strength metal energy-dissipating self-resetting damper, including a cylinder body 1, a guide rod 2, a first metal bellows 3, a butterfly spring group 4, a pressure sensor 5, a second metal bellows 6, and a guide rod 2 are respectively connected with the first metal bellows 3, the butterfly spring group 4, the pressure sensor 5 and the second metal bellows 6, and the guide rod 2 passes through the first connecting plate 7, the first limiting plate 9, and the first connecting bolt 15 The cylinder body 1 is connected with the third connecting bolt 17, the cylinder body 1 and the guide rod 2 are respectively provided with a first lug plate 104 and a second lug plate 203, and the first lug plate 104 and the second lug plate 203 are respectively connected to the building structural stress.

[0037] The end of the guide rod 2 is provided with a threaded joint 205 at the end, and the threaded joint at the end of the guide rod 2 is respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com