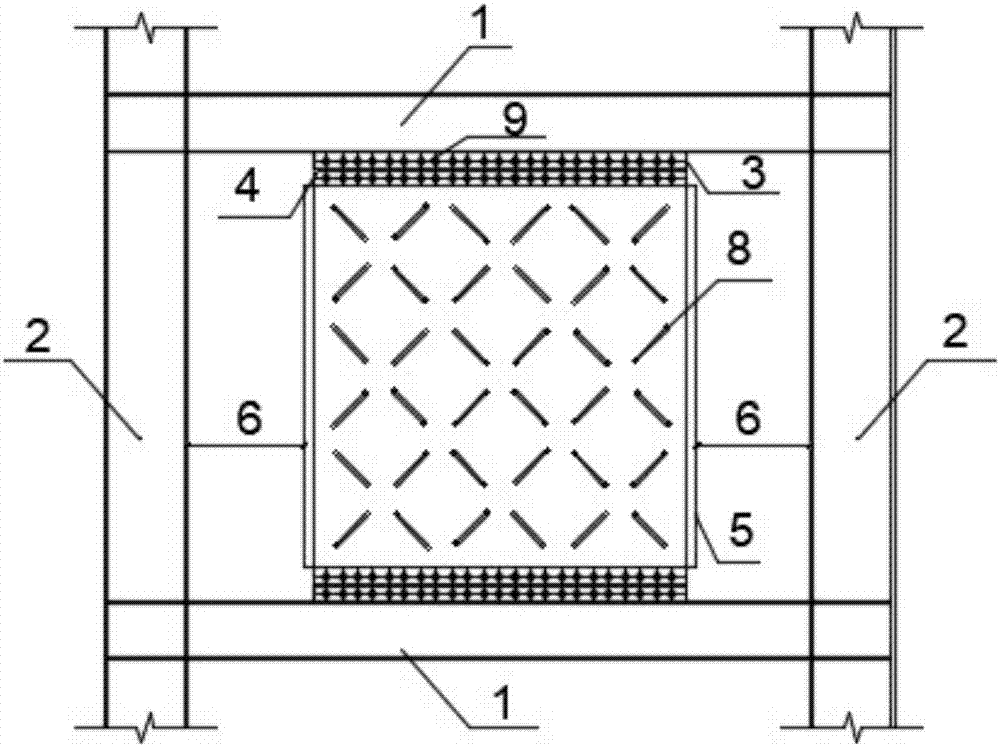

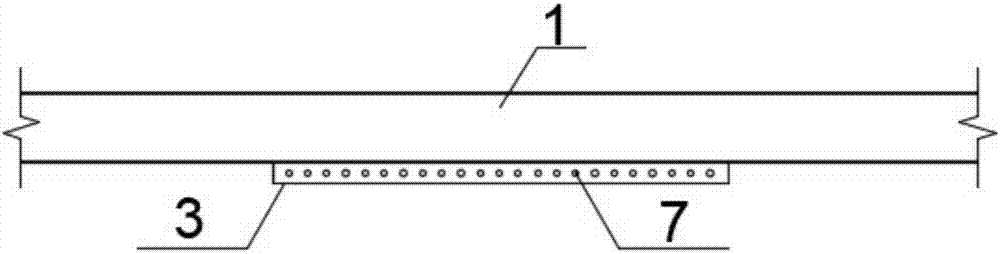

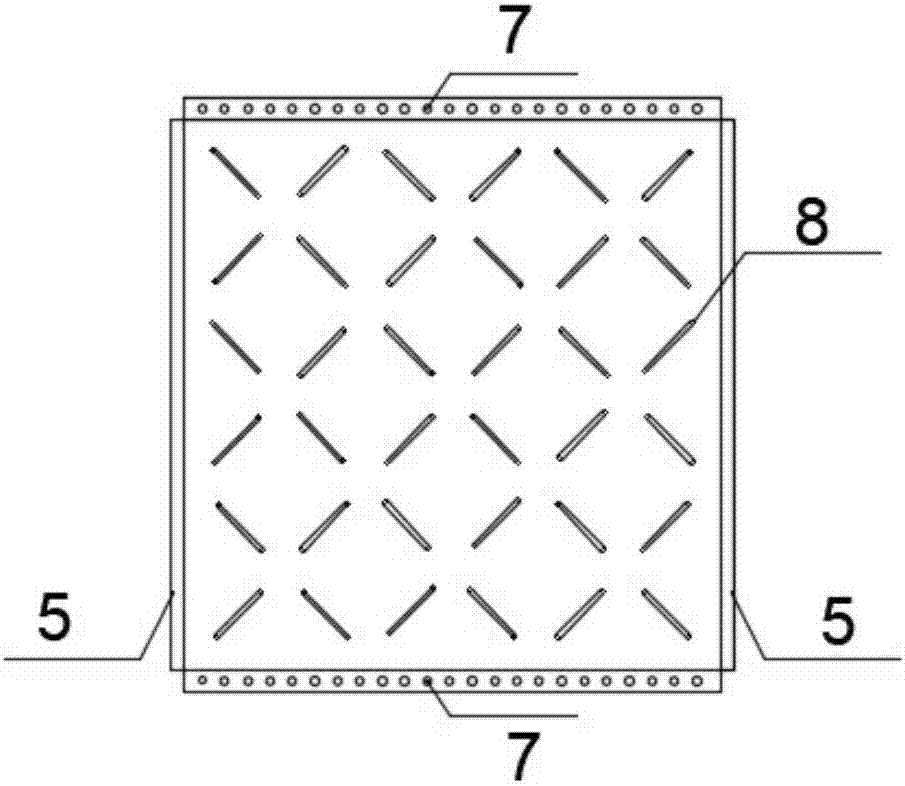

Oblique-slotted steel plate shear wall

A steel plate shear wall, steel plate technology, applied in the direction of wall, building, building type, etc., can solve the problems of complex installation, low load capacity, unreasonable load, etc., to improve the assembly rate, high bearing capacity, suitable for The effect of transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In the field of construction engineering technology, steel plate shear walls are currently widely used as components to bear structural horizontal forces and prevent structural shear damage. However, the existing steel plate shear walls on the market face shortcomings and shortcomings such as complicated installation, unreasonable force, low bearing capacity, and high processing costs, so they are not suitable for promotion and use.

[0042] The inventors of the present invention found that some steel plate shear walls with gaps have poor ductility, and it is difficult to form a complete tension field under the action of horizontal loads. The bearing capacity provided is limited, and generally cannot be used as a structural lateral force resistance system alone.

[0043] In order to solve the problems and deficiencies in the prior art, the inventors of the present invention tried to design a new type of steel plate shear wall with oblique slots, in order to obtain a stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com