Running wheel for suction machine

A technology of working wheel and suction machine, which is applied to components, mechanical equipment, machines/engines, etc. of pumping devices for elastic fluids. It can solve problems such as difficulty in fixing, reduce manufacturing costs, save plastics, and improve machinery /Effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

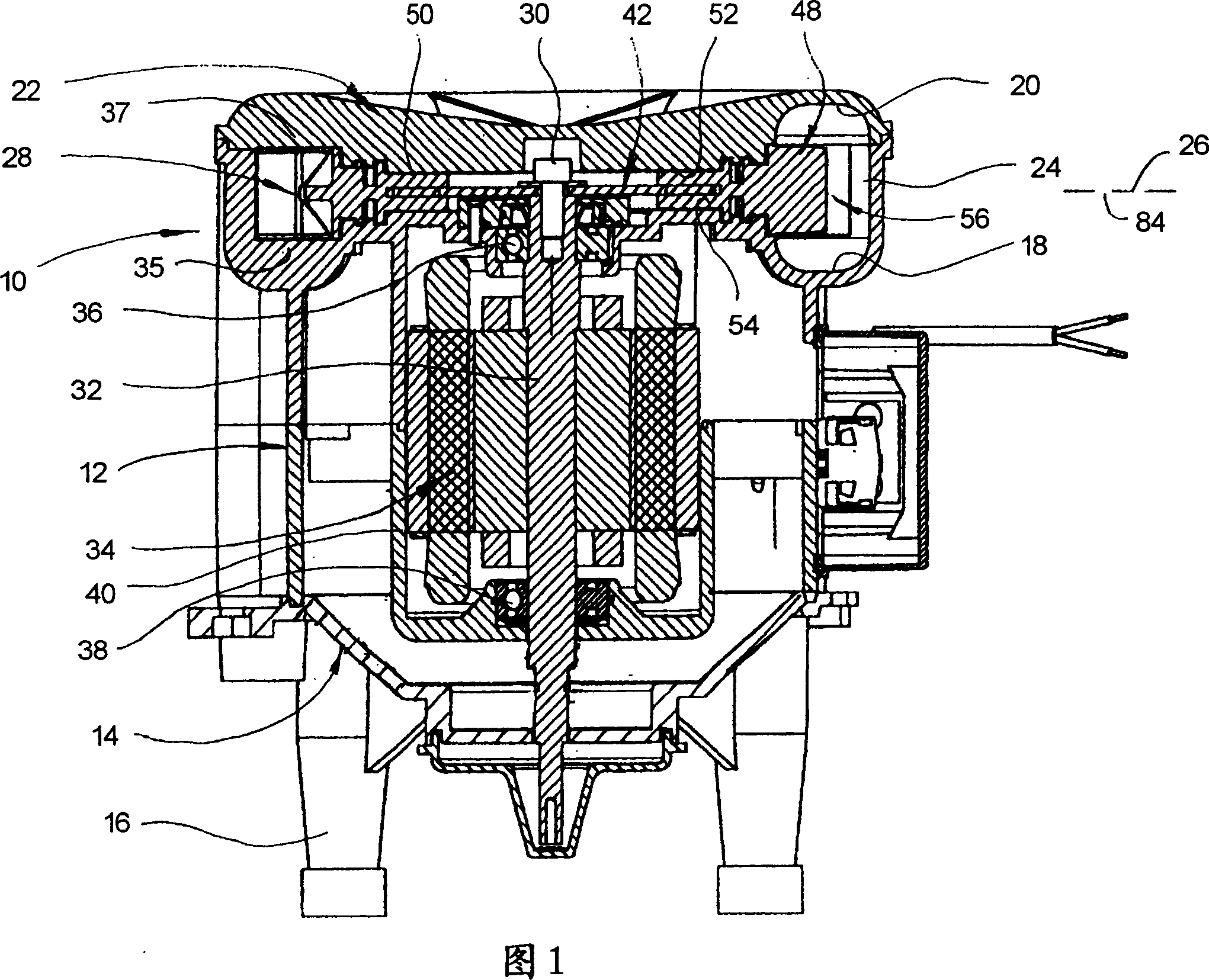

[0029] FIG. 1 shows a side channel suction machine with a housing generally indicated at 10 . The housing comprises a two-piece substantially cylindrical middle shell part 12 which is screwed to a lower shell part 14 supported by feet 16 .

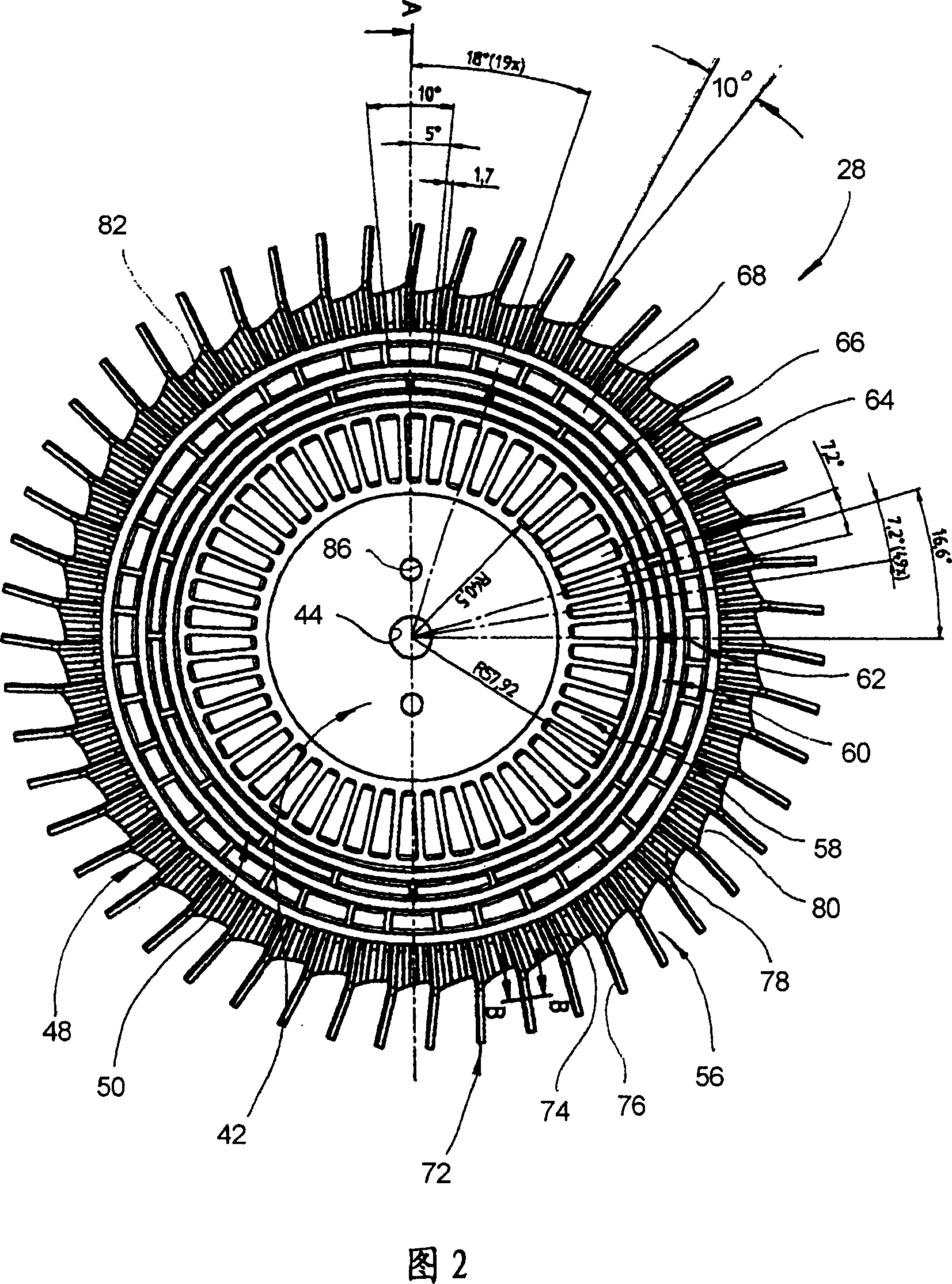

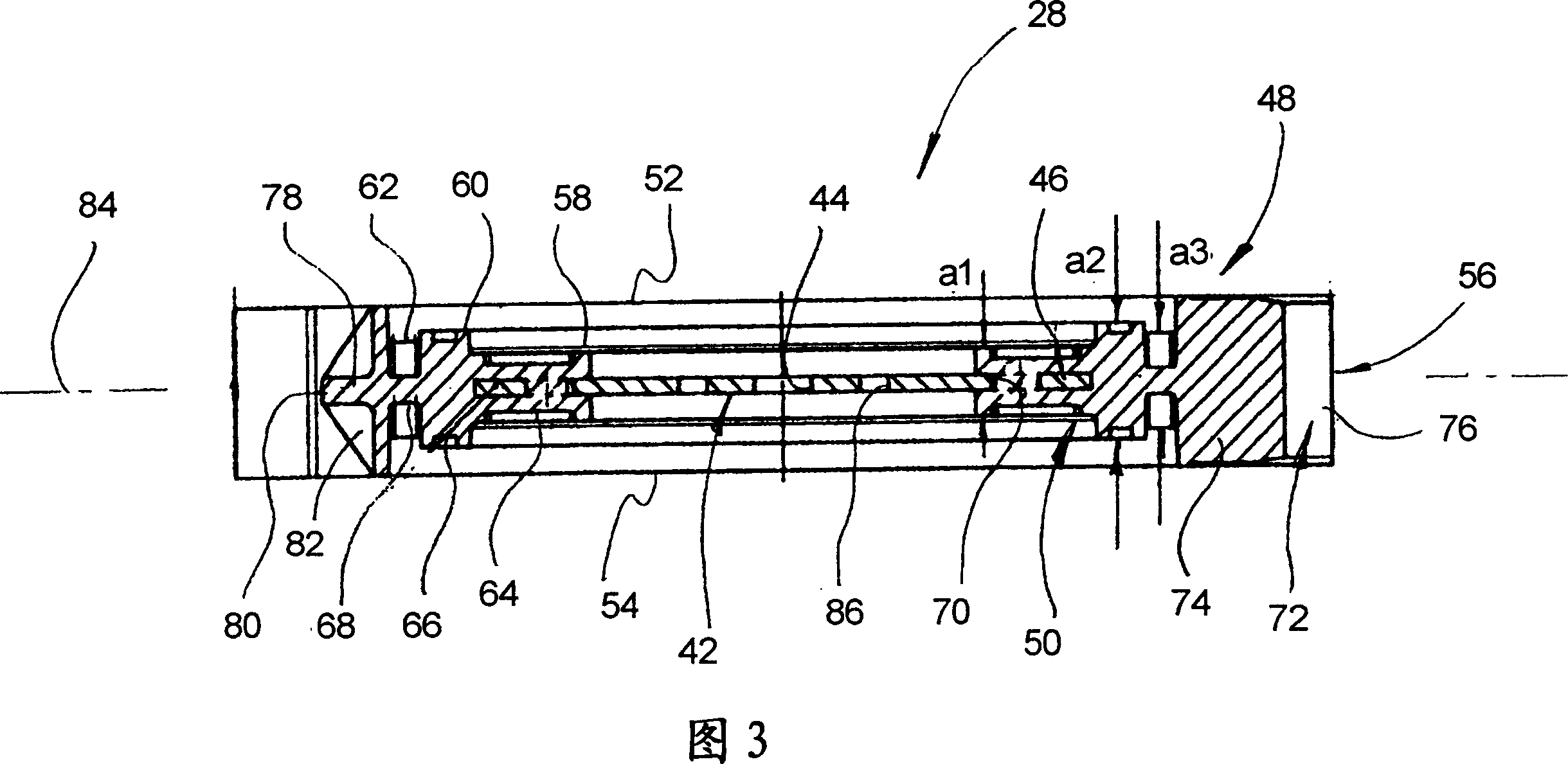

[0030] The upper end of the middle shell portion 12 is tapered and defines a groove portion 18 which, together with an aligned groove portion 20 in the upper shell portion 22, defines a working space 24 . The working space has a circumferentially increasing cross-section and is symmetrical about a median plane 26 .

[0031] In the working space 24 a working wheel, indicated in its entirety at 28 , rotates and is firmly connected by means of screws 30 to the end of a motor shaft 32 , which belongs to the electric machine in its entirety at 34 . The motor shaft 32 is supported on bearings 36 , 38 supported by a motor housing 40 .

[0032] The access to the workspace 24 can be conceived as opening into the workspace in front of the drawing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com