Intelligent electricity-saving device for high-voltage ball miller

A power-saving device and ball mill technology, which is applied in grain processing and other directions, can solve problems such as affecting the working conditions of user equipment, large temperature rise of motor work, and insignificant energy-saving effect, so as to reduce iron loss and copper loss, reduce working temperature rise, The effect of working temperature rise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

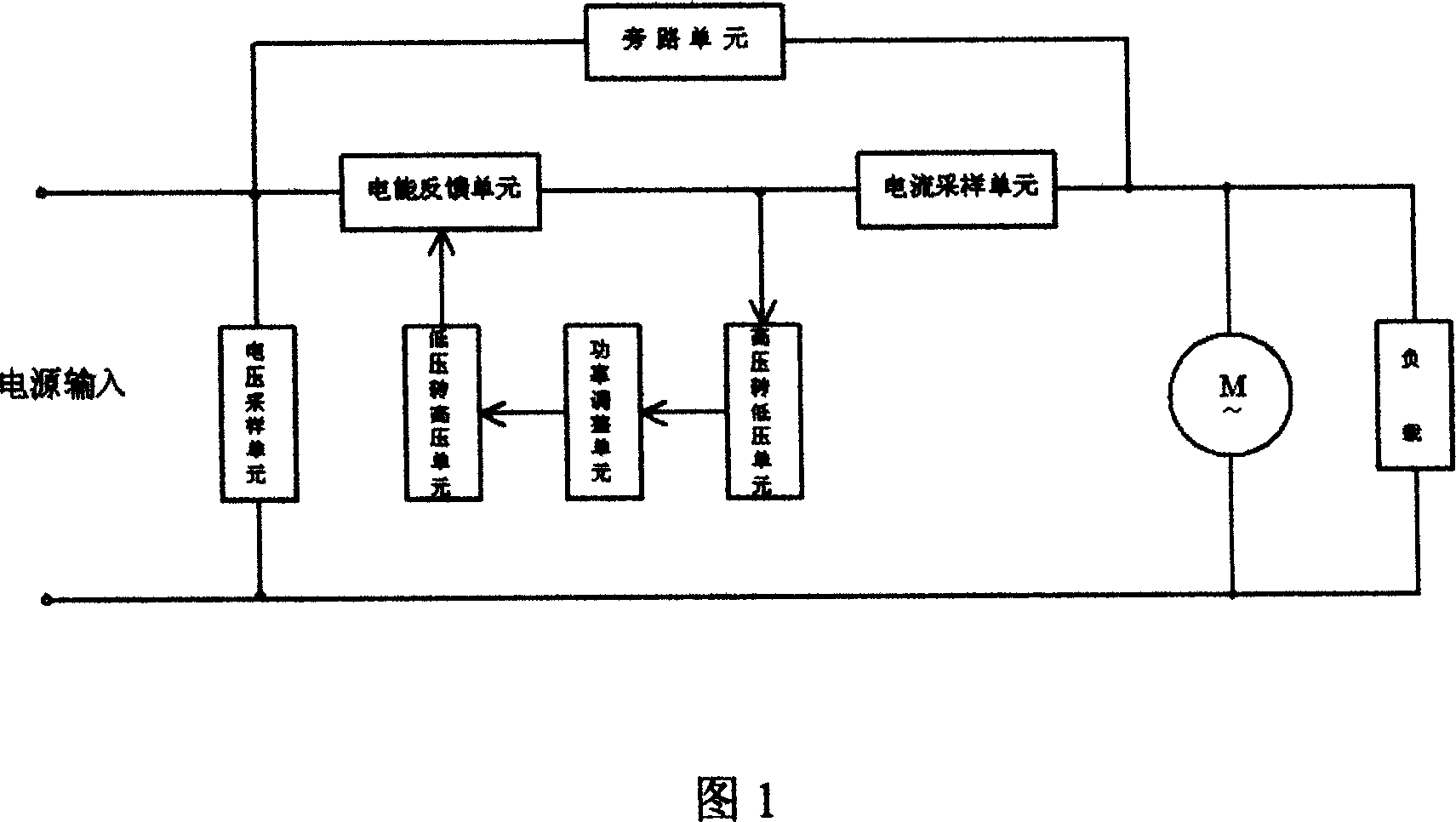

[0026] As shown in Figure 1, the device consists of the following parts: ① Electric energy feedback unit ② High-voltage to low-voltage unit ③ Power adjustment unit ④ Low-voltage to high-voltage unit ⑤ Voltage sampling unit ⑥ Current sampling unit ⑦ Bypass unit ⑧ SCR unit. ③The power adjustment unit calculates and processes the signals sent by the current and voltage sampling unit, and then compares them with the inherent parameters of the motor and related operating curves to adjust the output power of the motor so that the output power matches the power required by the load. At the same time, the excess electric energy is fed back to the grid through the electric energy feedback unit, and the energy-saving concept of "what you use is what you need" is implemented to achieve the purpose of energy saving. The bypass unit is used as a backup unit in case of sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com