Double revolution surface quadric enveloping worm gear pairs and its production method

A toroidal worm, secondary enveloping technology, applied in worms, manufacturing tools, gear teeth manufacturing tools, etc., can solve the problems of complex adjustment of the tool seat structure, decreased micro meshing quality, undercutting or sharpening of the edge tooth tip. , to achieve the effect of shortening the grinding auxiliary time, long service life and reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention will be further described:

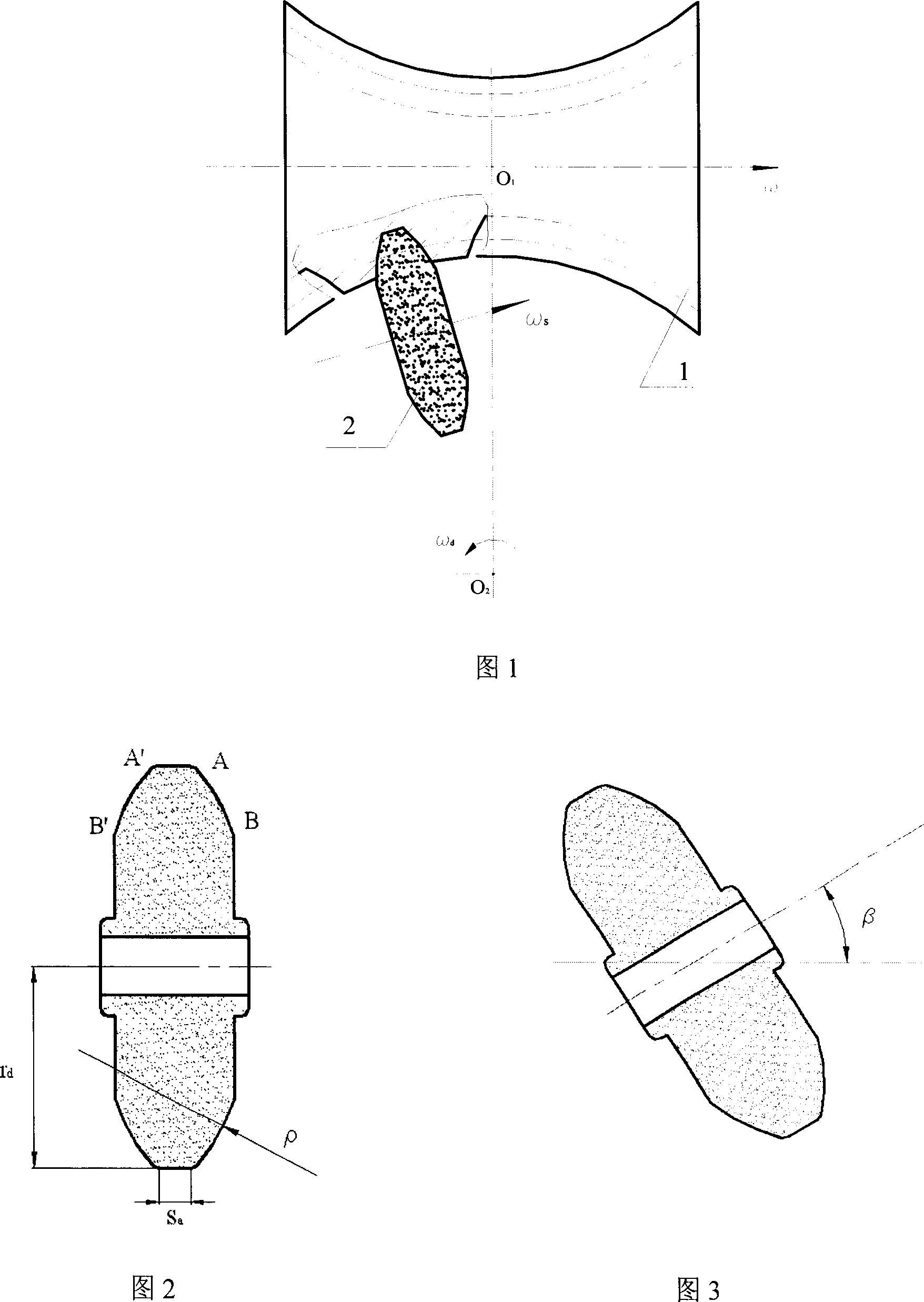

[0012] A method for manufacturing a quadratic enveloping toroidal worm pair with a double-revolved curved surface. The fine grinding process of the toroidal worm [1] is shown in Figure 1. The toroidal worm [1] blank and the tool seat are respectively at angular speed ω and ω d Rotate around their respective axes, the axis of the tool seat coincides with the axis of the worm gear, and the speed ratio between the blank of the torus worm [1] and the tool seat is equal to the transmission ratio of the torus worm pair, i.e. 1d = i 12 . Cutter [2] is a grinding wheel (in this embodiment, the cutter is specifically a grinding wheel [2]), and the grinding wheel is at an angular velocity ω s Rotate around its own axis.

[0013] The plane curve AB selected in this embodiment, as shown in Figure 2, is a circular arc as the working profile in the section of the grinding wheel shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com