Transferring device

A technology of conveying device and conveying guide rail, which is applied to electromechanical devices, conveyors, conveyor objects, etc., can solve problems such as sagging of structures, difficulty in holding coils and permanent magnets, and increased installation costs of conveying devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

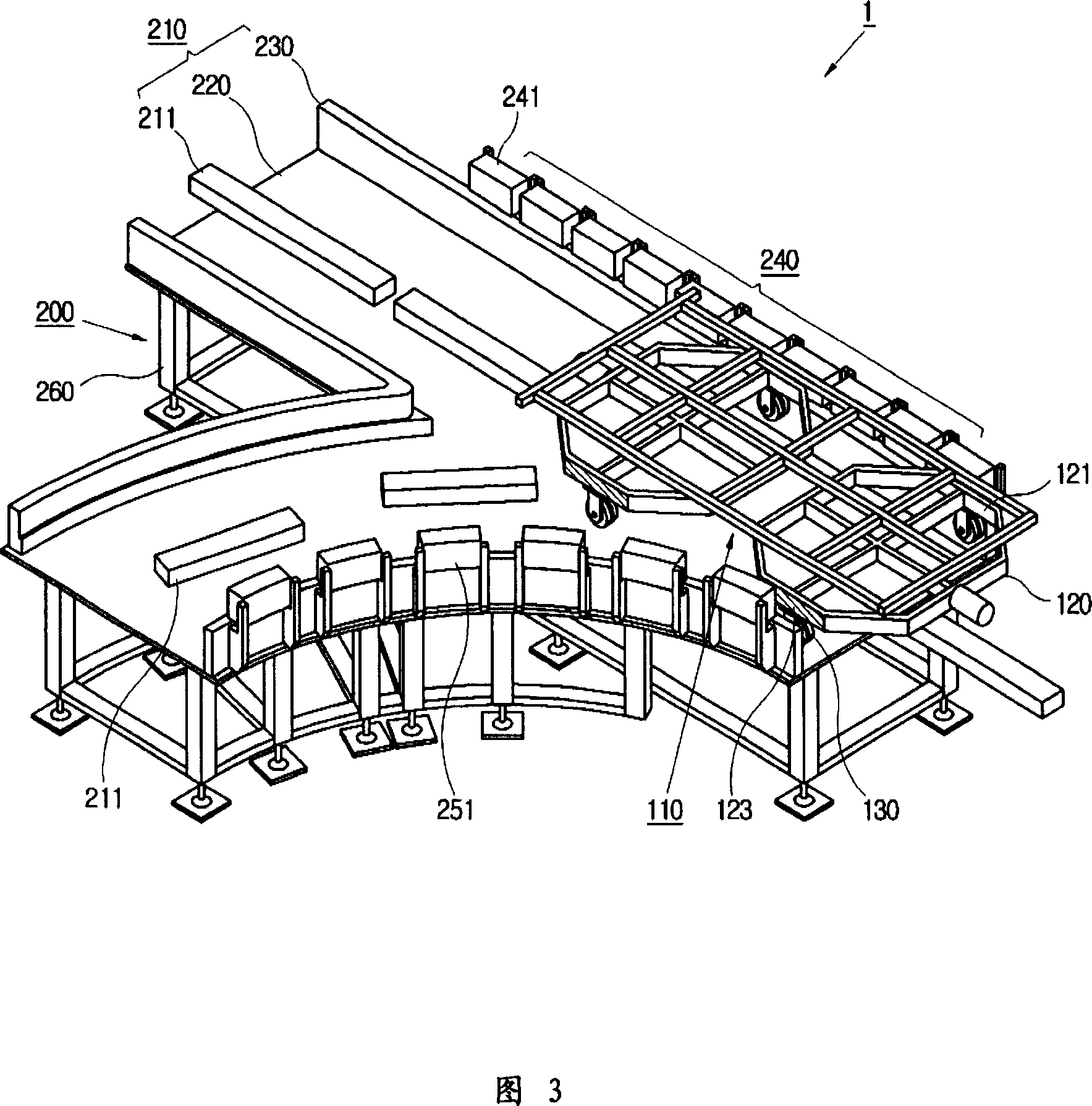

[0023] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0024] Fig. 3 is a schematic structural view of the branching part of the conveying device 1 provided according to the present invention, Fig. 4 is a top view of the conveying device 1 provided according to the present invention, Fig. 5 is a cross-sectional view of the branching part in Fig. 4, Fig. 6 It is a schematic bottom view showing the structure of the transport vehicle 100 provided according to the present invention.

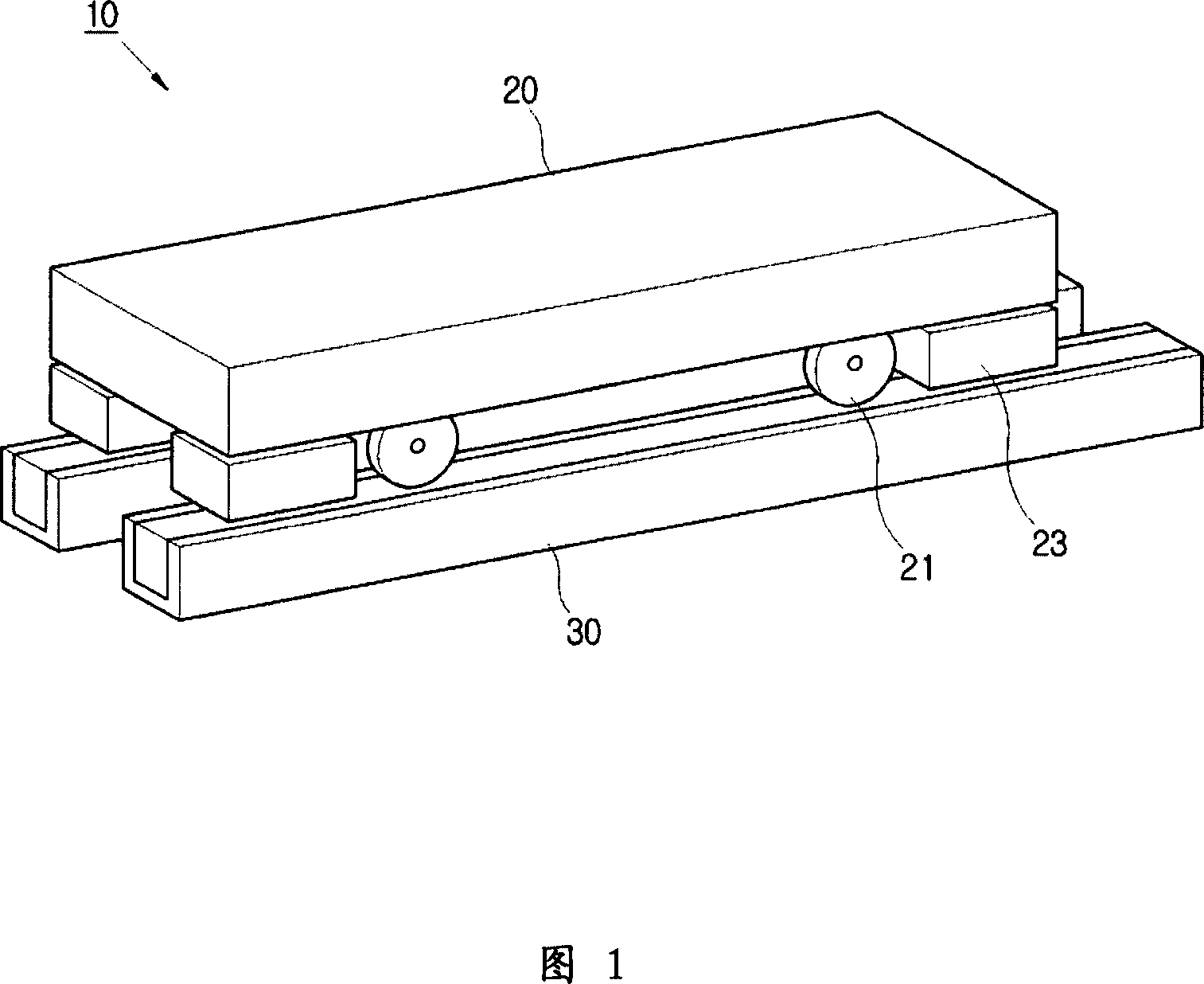

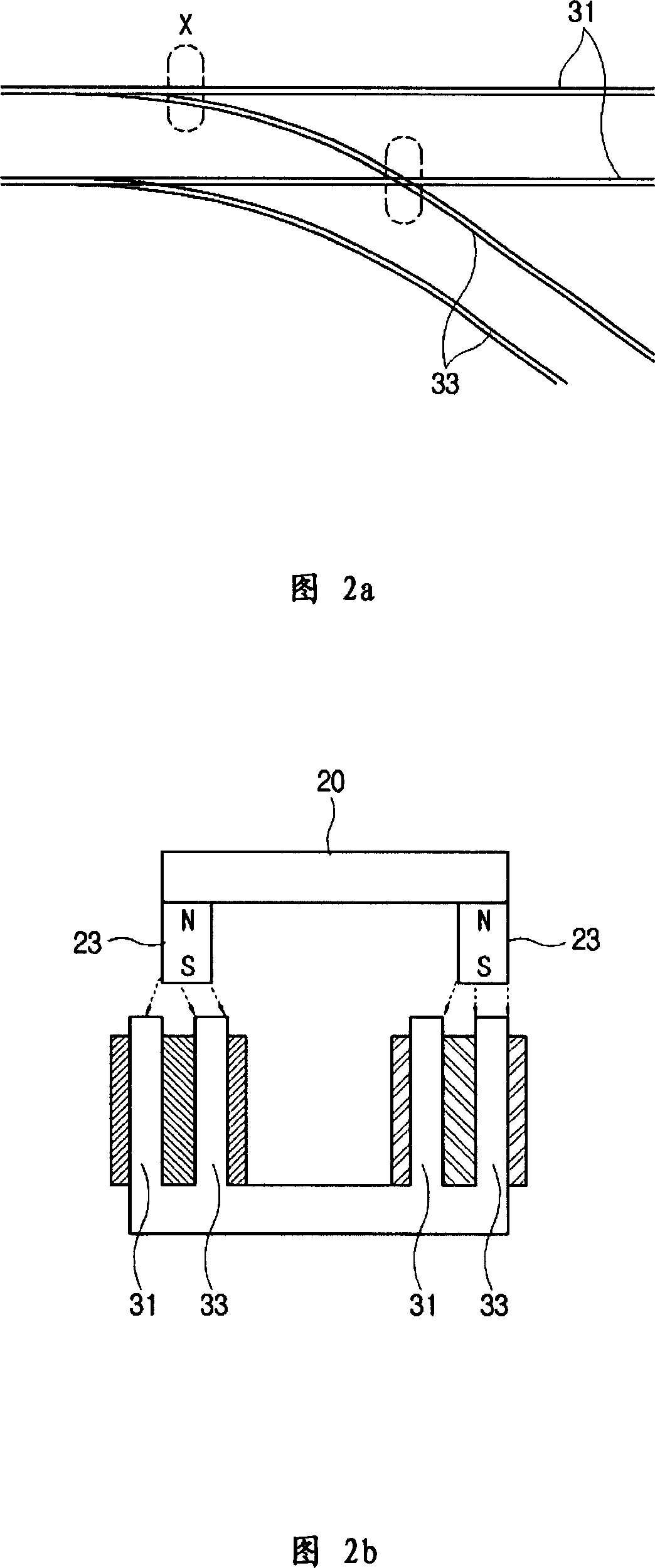

[0025] As shown in these figures, the conveying device 1 provided according to the present invention includes a carrier cart 100 for loading articles and a transfer rail 200 for transporting the carrier cart 100 .

[0026] The truck 100 provided according to the present invention comprises: a main body 110 for loading articles; a magnetic induction guide plate part 120 with magnetic induction guide plates 121, 123 arranged on the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com