Method for measuring return flow in petroleum drilling and device therefor

A flow measurement device, oil drilling technology, applied in the directions of measurement, earthwork drilling, flushing wellbore, etc., can solve the problems of affecting measurement accuracy, unreachable, long lag time, etc., to achieve high test accuracy, easy installation, data Small error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

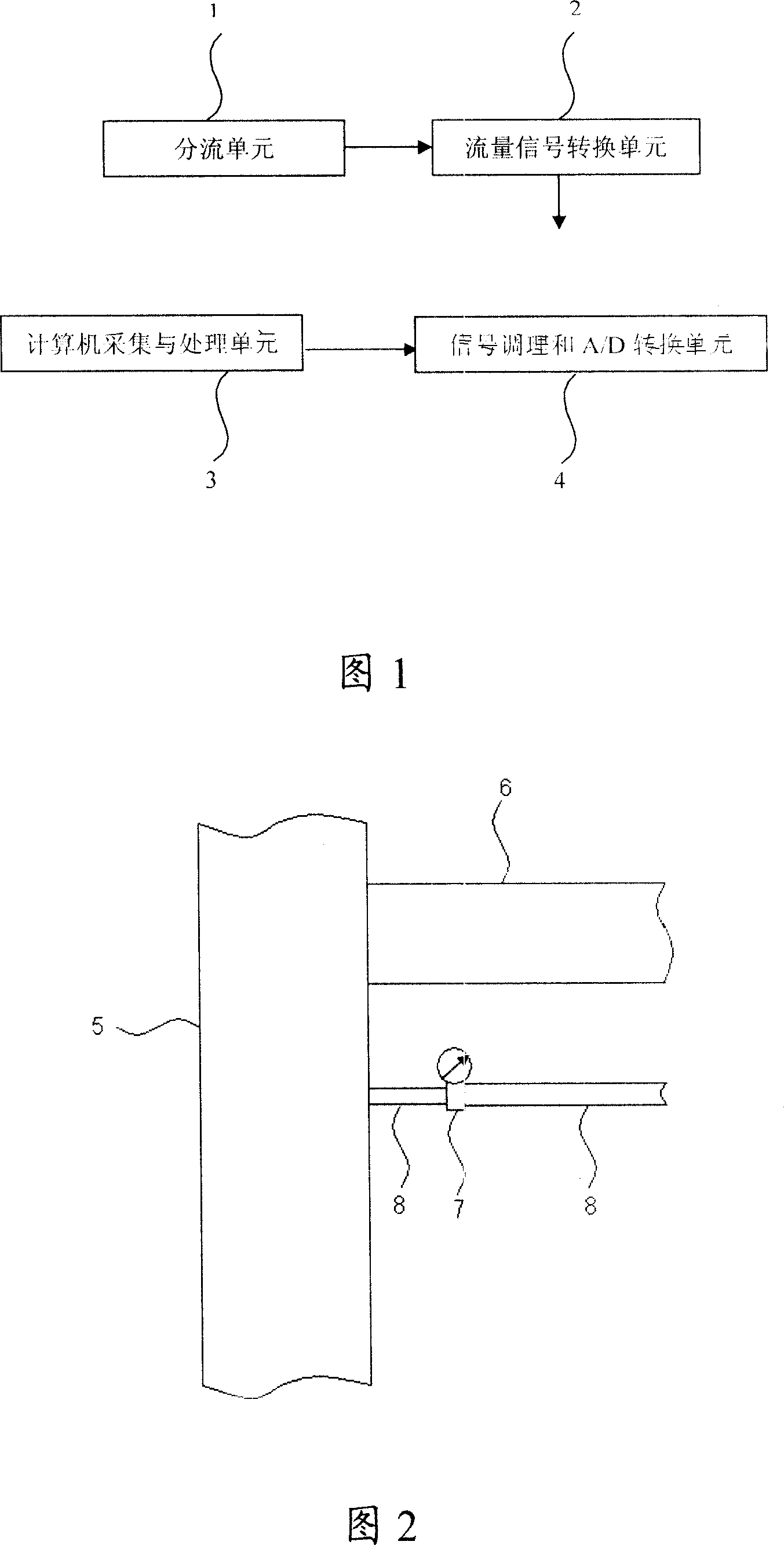

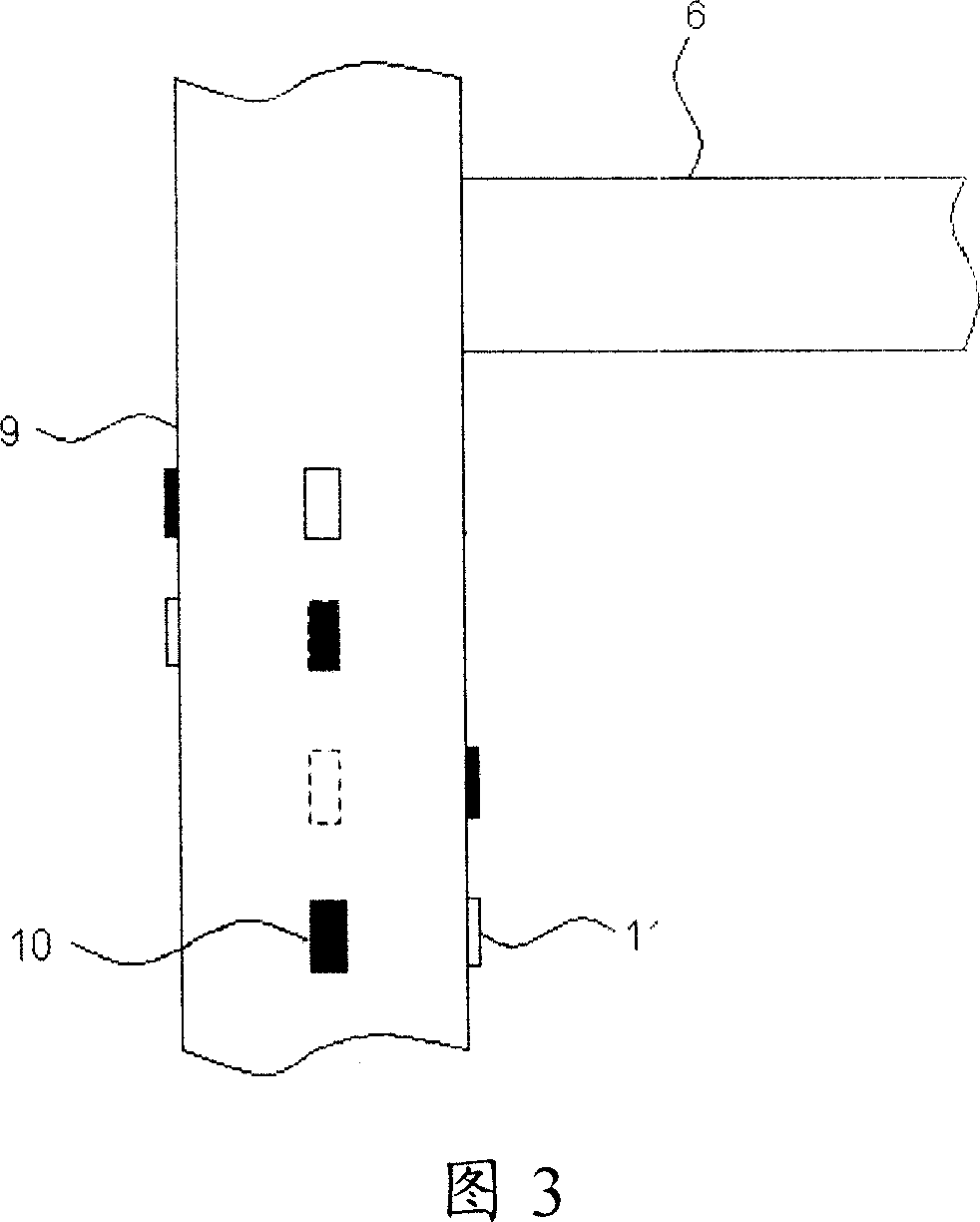

[0031] As shown in Figures 1, 2, and 3, the shunt-type small-section measuring device is equipped with a shunt unit 1, a flow signal conversion unit 2, a signal conditioning and A / D conversion unit 4, and a computer acquisition and processing unit 3. Wherein, the splitting unit 1 is composed of branch pipes 8 with different diameters, which are divided into two by the flow signal conversion unit 2 , and the flow signal conversion unit 2 is composed of a high-sensitivity flowmeter 7 . The flow signal conversion unit 2 is connected to the signal conditioning and A / D conversion unit 4 by an anti-interference signal line, and the signal conditioning and A / D conversion unit 4 is connected to the computer acquisition and processing unit 3 by a data line.

[0032] Install a branch pipe 8 parallel to the return pipeline at 30cm below the mud return pipeline 6. Selecting 30cm is to consider that the installation of the branch pipe will be convenient and safe. If the branch pipe is too f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com