Megawatt-level water-cooled dual-feed wind asynchronous generator

A wind power generator, double-fed asynchronous technology, applied in asynchronous induction motors, cooling/ventilation devices, electromechanical devices, etc., can solve the problems of power quality improvement, work reliability improvement, etc., to achieve convenient installation and manufacture, and long motor life , the effect of low temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

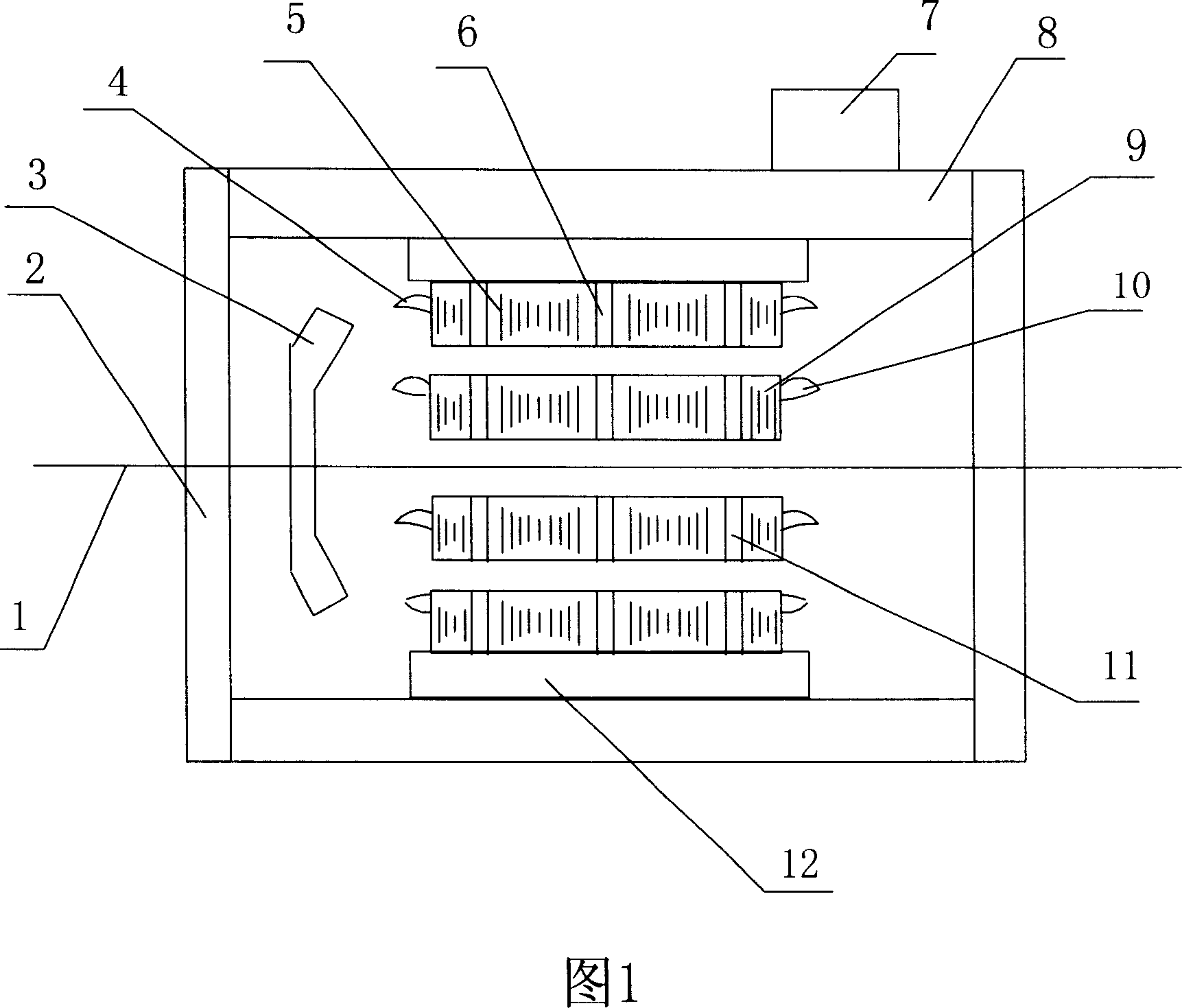

[0008] As shown in Fig. 1, the present invention includes machine base 8, machine cover 2, rotating shaft 1, fan 3, stator iron core 5, rotor iron core 9, inner rib 12, water-cooling machine base inlet and outlet device 7, machine cover 2 connected At the front and rear ends of the machine base 8, it is characterized in that a water-cooled machine base water inlet and outlet device 7 is connected above the machine base 8, a fan 3 is connected on the shaft 1 in the inner cavity of the machine base, a stator winding 4 is connected on the stator core 5, and the winding It is a concentric discontinuous single-layer winding, and the connection method is △ connection. The stator core 5 is provided with radial air ducts 6 for the stator core. The rotor core 9 is connected with the rotor winding 10, and the rotor winding 10 adopts the form of wave winding. The connection method is the Y connection method, the rotor core 9 is provided with a rotor core radial air duct 11, and the machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com