Double hydraulic rolling tool with equal rolling force

A technology of rolling force and dual hydraulic pressure, which is applied in the field of rolling tools of rolling force and free surface rolling tools, which can solve the problem of limiting the applicable range and effect of rolling process, difficulty in keeping the rolling depth basically constant, and affecting rolling The overall effect and other issues, to achieve the effect of convenient and accurate adjustment, wide versatility, and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings, but the embodiment of the present invention is not limited thereto. The installation method of the rolling tool needs to adopt different clamping handles or tooling according to the different machine tools used.

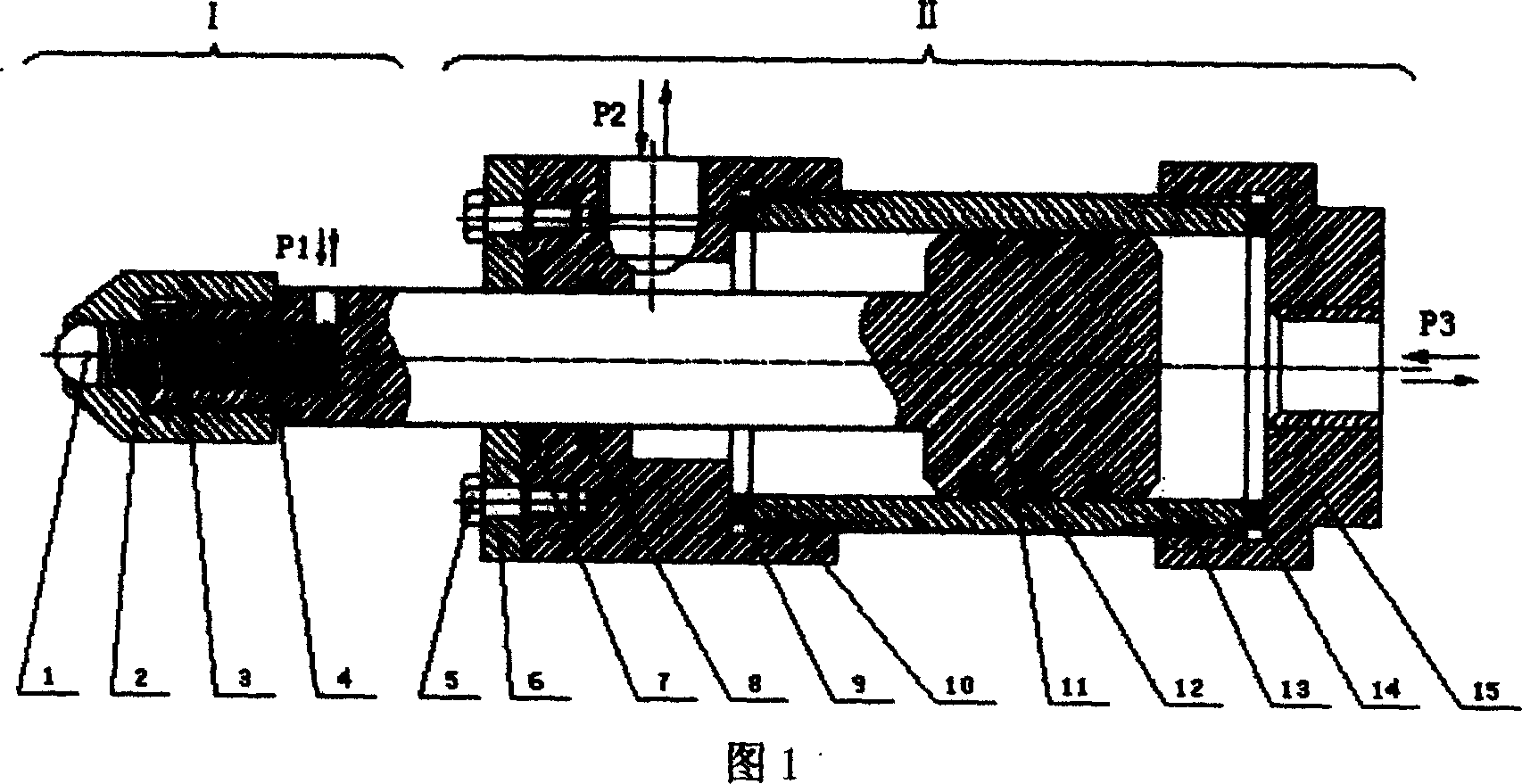

[0018] Figure 1 shows an embodiment of the present invention, which is realized by the following structure, including two parts: the one is a small displacement fine-tuning mechanism 1, which consists of a rolling body 1, a rolling body holding sleeve 2, a compression spring 3 and a holding The sleeve sealing ring is composed of 4. The second is the large displacement main adjustment mechanism II, which consists of gland screw 5, gland 6, dustproof ring 7, piston rod seal ring 8, front end cover seal ring 9, front end cover 10, piston with rod 11, piston seal 12, cylinder Tube 13, rear end cover sealing ring 14 and rear end cover 15 are ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap