Energy-saving high speed hovercraft hull

A hovercraft, energy-saving technology, applied in the direction of air cushion, transportation and packaging, vehicle parts, etc., can solve the problems of complex structure, limitations, generally only a few hundred tons, and astonishing energy consumption, so as to improve transportation efficiency and reduce weight. , the effect of huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

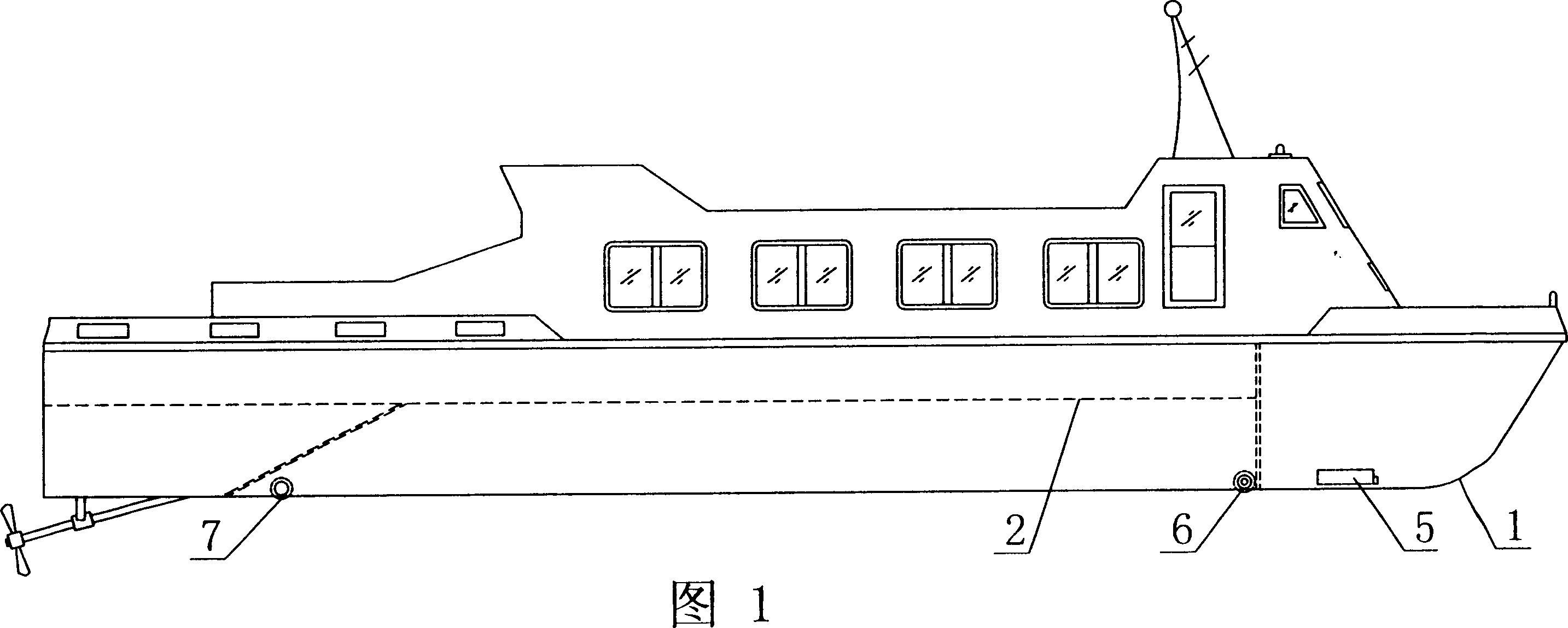

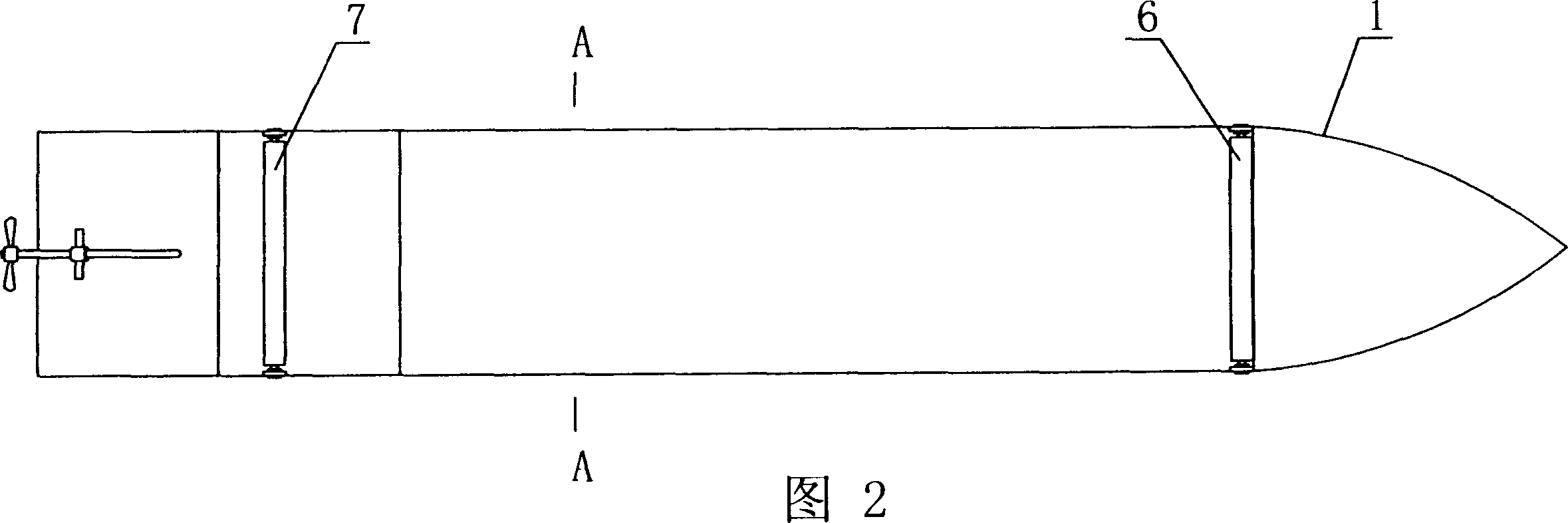

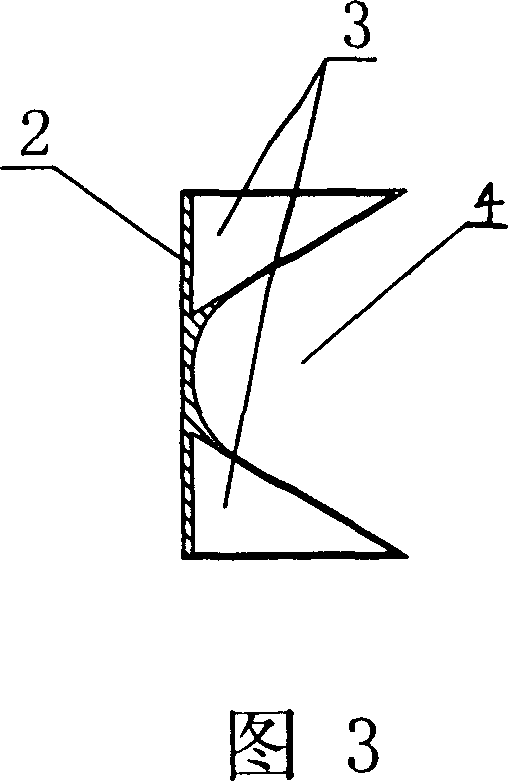

[0019] Referring to Fig. 1, Fig. 2, shown in Fig. 3, the energy-saving type high-speed hovercraft hull of the present invention comprises a hull 1, and at the middle part of the bottom of the hull 1 is an upward concave concave bottom 2, on which concave bottom 2 is provided with two sides. Sealed air chamber 3 and an air chamber 4 with an open bottom in the middle; the cross-sectional shape of the sealed air chamber 3 is an inverted triangle, and the sealed air chamber 3 and the air chamber 4 are arranged symmetrically with the longitudinal central axis of the hull 1; Air pressurization device 5, the high-pressure outlet of air pressurization device 5 communicates with each air chamber 4 respectively; The sealed air chamber 3 on the concave bottom 2 and the junction of the air chamber 4 and the bottom of the bow are provided with a front sliding roller 6, the The two ends of the front sliding roller 6 are pivotally arranged on the side panels on both sides of the hull 1; the j...

Embodiment 2

[0021] Referring to Fig. 1, Fig. 4, shown in Fig. 5, the hull of the energy-saving high-speed hovercraft of the present invention is basically the same as that of Embodiment 1, and four sealed air chambers 3 and three open air chambers 4 are provided on the concave bottom 2 Composition; the cross-sectional shape of the airtight chamber 3 is an inverted triangle, and the airtight chamber 3 and the airchamber 4 are arranged symmetrically with the longitudinal central axis of the hull 1 .

Embodiment 3

[0023] Referring to Fig. 1, Fig. 6, shown in Fig. 7, the hull of the energy-saving high-speed hovercraft of the present invention is basically the same as Embodiment 1, and seven sealed air chambers 3 and six open air chambers 4 are arranged on the concave bottom 2 Composition; the cross-sectional shape of the airtight chamber 3 is an inverted triangle, and the airtight chamber 3 and the airchamber 4 are arranged symmetrically with the longitudinal central axis of the hull 1 .

[0024] During concrete use of the present invention, each air chamber 4 is inflated with an air pump, and water is discharged outwards from each air chamber 4, so that the hull 1 reduces the draft; Pressure device 5 is constantly inflated to air chamber 4, guarantees the normal draft of hull, further reduces sailing resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com