Jet wheel engine

A technology of engines and spray wheels, which is applied in the direction of machines/engines, gas turbine devices, mechanical equipment, etc., and can solve problems such as inability to operate, low mechanical efficiency, and small effective rotational torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

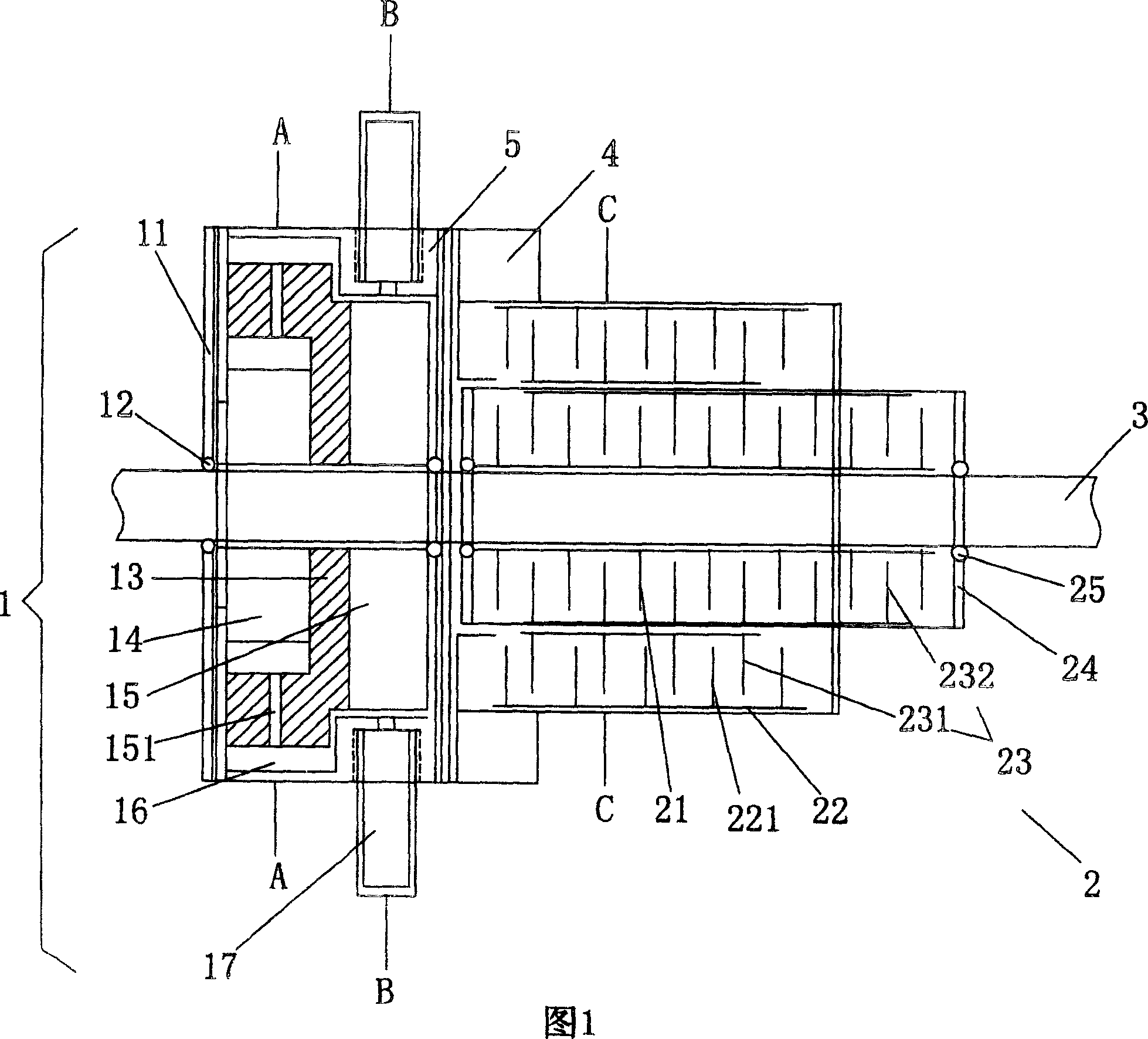

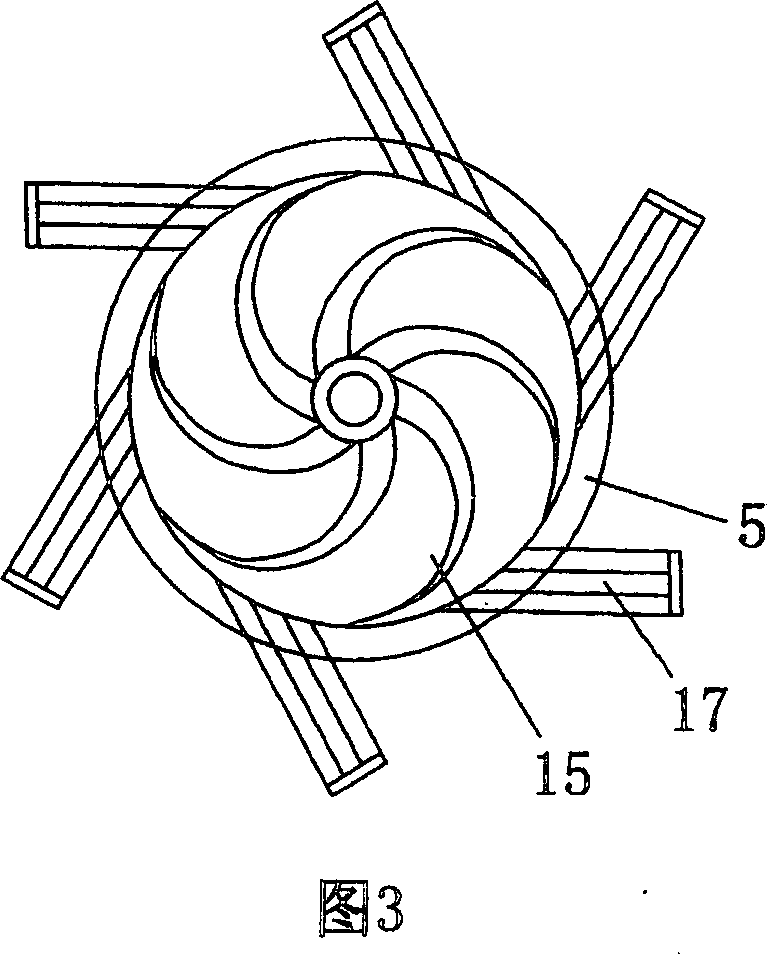

[0030] As shown in Figure 1, the spray engine of the present invention is made up of axial flow turbine 1, shaft row turbine 2 and turbine casing 5, and turbine casing 5 is covered outside the axial flow turbine 1 and shaft row turbine 2, and the axial flow turbine 1 is two The end is installed on the turbine shaft 3 by the ring flower-shaped wheel cover 11 and bearing 12. The axial flow turbine is composed of the turbine shaft 3, the flywheel 13, the centrifugal impeller 14, the turbine impeller 15, and the explosion chamber 17. The flywheel 13, the centrifugal impeller 14, the turbine The impellers 15 are respectively installed on the turbine shaft 3, the centrifugal impeller 14 is in contact with the wall surface of the flywheel 13, the flywheel 13 is in contact with the wall surface of the turbine impeller 15, the centrifugal impeller 14 is arranged in the inner cavity of the flywheel 13, and the circumference of the flywheel 13 is processed with anti-rotation tangent direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com