Capacitive physical quantity sensor and method of diagnosing the same

A physical quantity sensor, sensor technology, applied in the direction of capacitance measurement, conversion of sensor output, transmission of sensing components by electromagnetic/magnetic devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

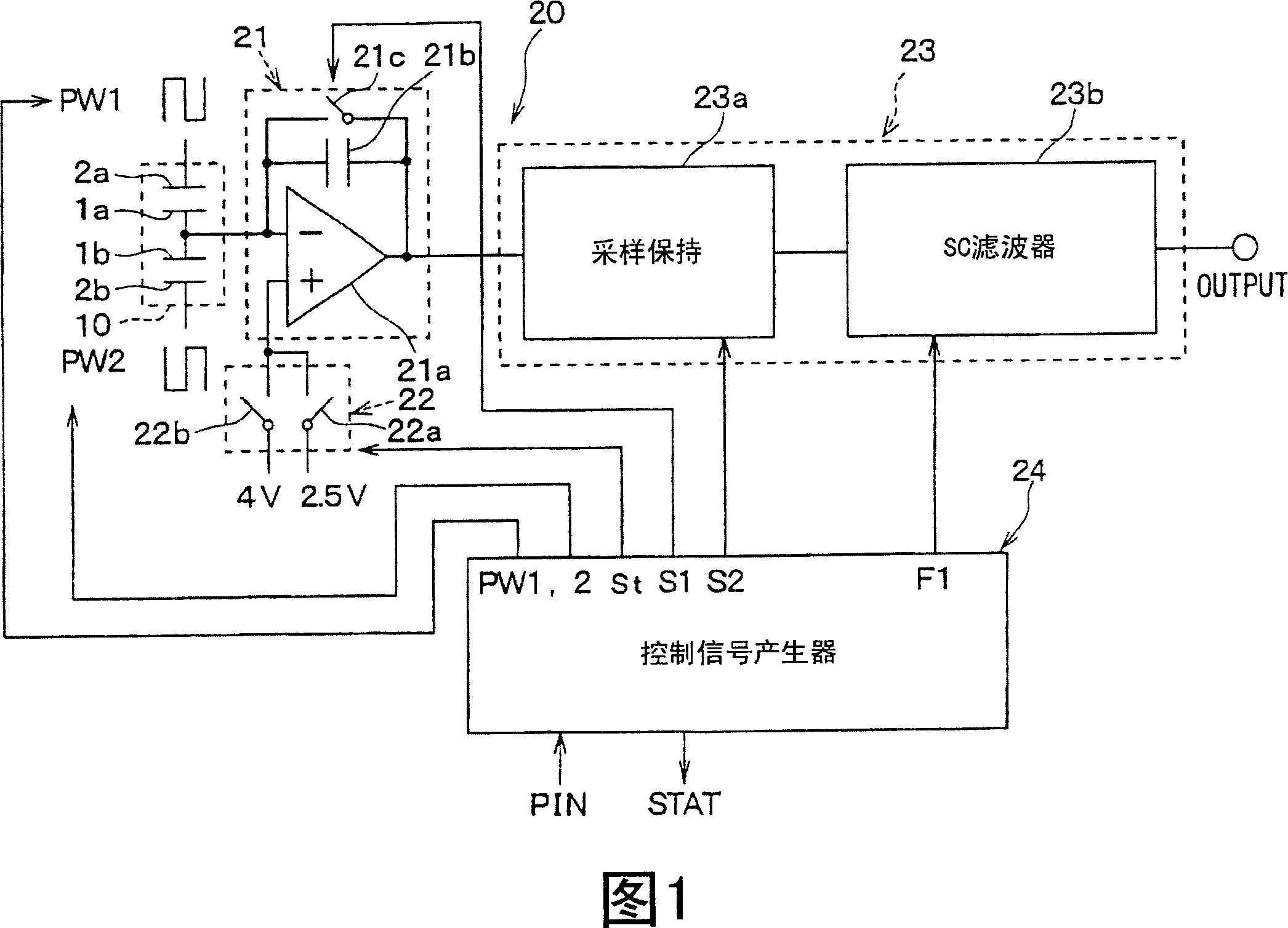

Method used

Image

Examples

no. 2 example

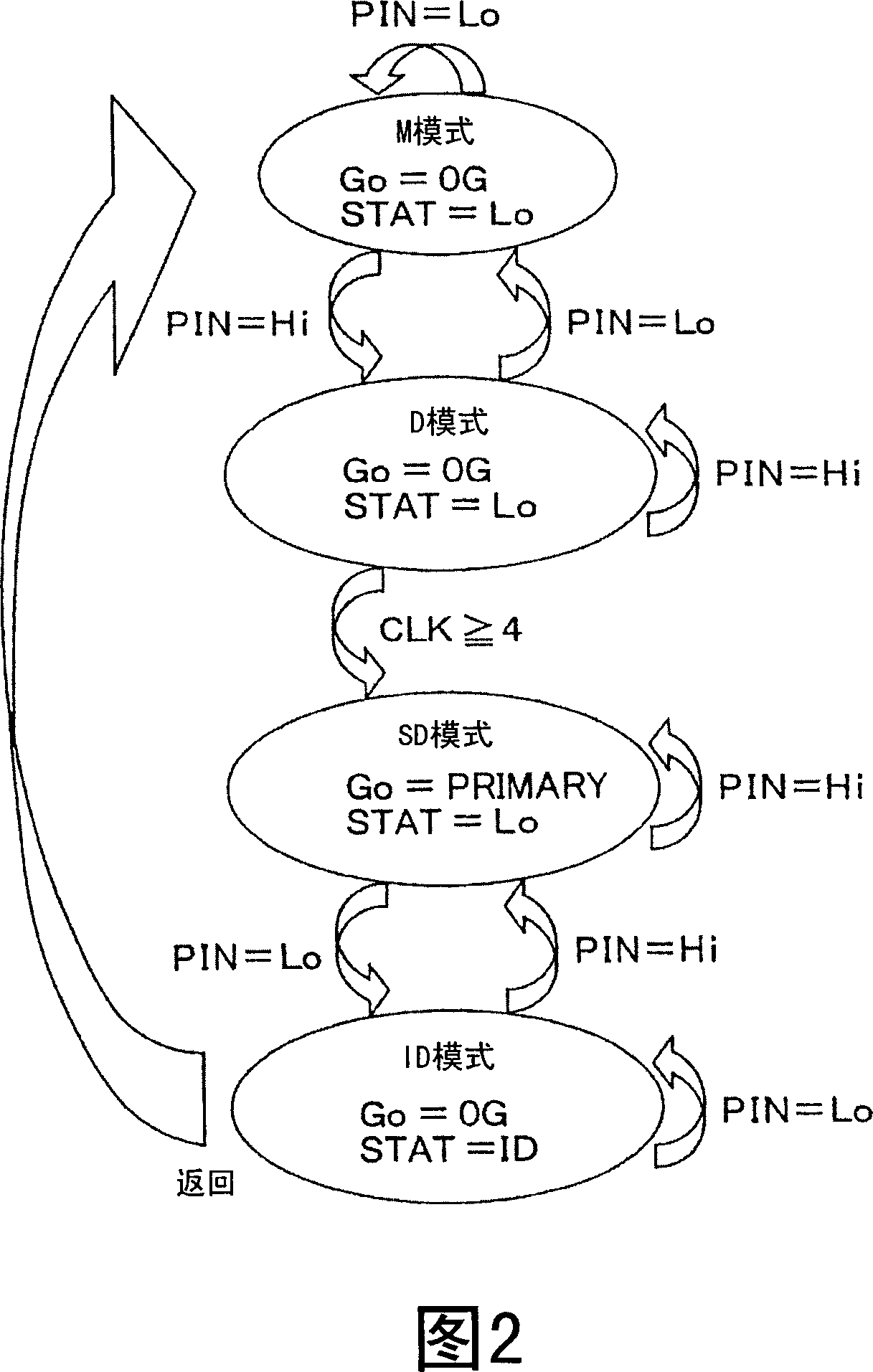

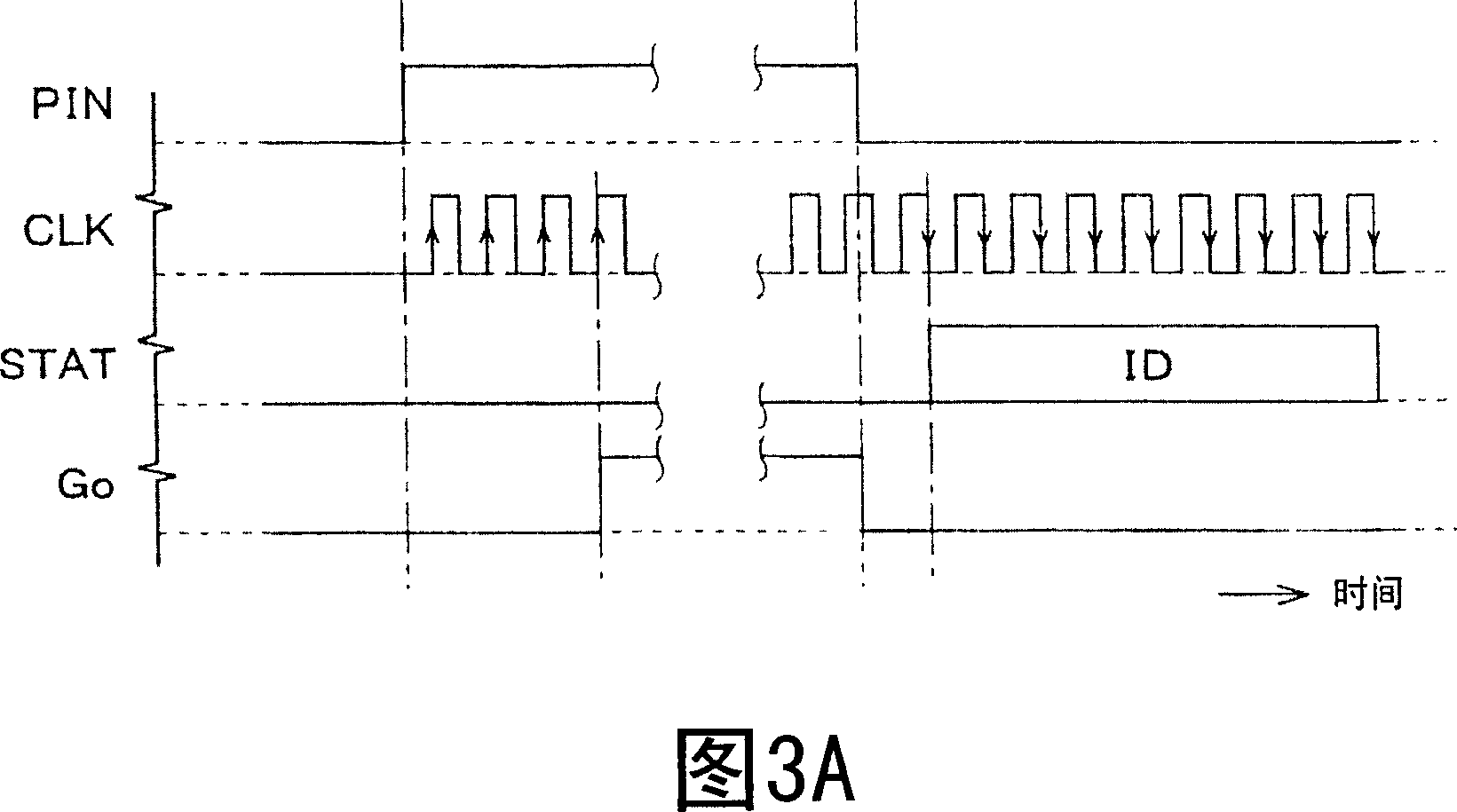

[0049] In the second embodiment, whether a PIN signal is indicated as a signal for self-diagnosis or is set to Hi by external noise is determined by using a plurality of PIN signals. Other parts can be made similar to those of the first embodiment, and descriptions of these other parts are omitted.

[0050] In the self-diagnosis mode, a signal indicating self-diagnosis, that is, a PIN signal is set to Hi in the control signal generating circuit 24 . In contrast, the PIN signal can be set to Hi by external noise. When the PIN signal is set to Hi, it is determined by using the clock signal CLK generated by the clock in the circuit 24 whether the PIN signal is a signal indicating self-diagnosis or is set to Hi by external noise.

[0051] First, when the PIN signal is set to Hi, a signal is output from the circuit 24, and the output potential of the STAT terminal is set to Hi in synchronization with the rising edge of the PIN signal. Specifically, an operation similar to that in...

no. 3 example

[0063] In the third embodiment, the acceleration sensor has two sensitivities for a single axis. Other parts can be made similar to those of the first embodiment, and descriptions of other parts will be omitted.

[0064] As shown in FIG. 6 , an integrated circuit (IC) package 30 (pressure sensor) includes a sensor element 10 , a C-V conversion circuit 21 , a switch circuit 22 , a signal processing circuit 23 and a control signal generation circuit 24 . The IC 30 further includes a power supply terminal 30a, a first output terminal 30b, a second output terminal 30c, a ground (GND) terminal 30d, a STAT terminal 30e and an input terminal 30f. These six terminals 30a-30f correspond to a lead frame 35 described below. The power supply terminal 30 a supplies the driving voltage VCC to the IC 30 . The first output terminal 30b outputs an output signal Go1. The second output terminal 30c outputs an output signal Go2. The GND terminal 30d is connected to the reference potential GND...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com