Photomagnetic mixed storing material with high-coercive fore and producing method thereof

A hybrid storage, opto-magnetic technology, applied in the direction of information storage, magnetic layer coating, recording information storage, etc., can solve the problems of difficult guarantee of material performance, complex preparation process, etc., achieve significant application value, improve coercive force, storage The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment one: component one TbFeCo

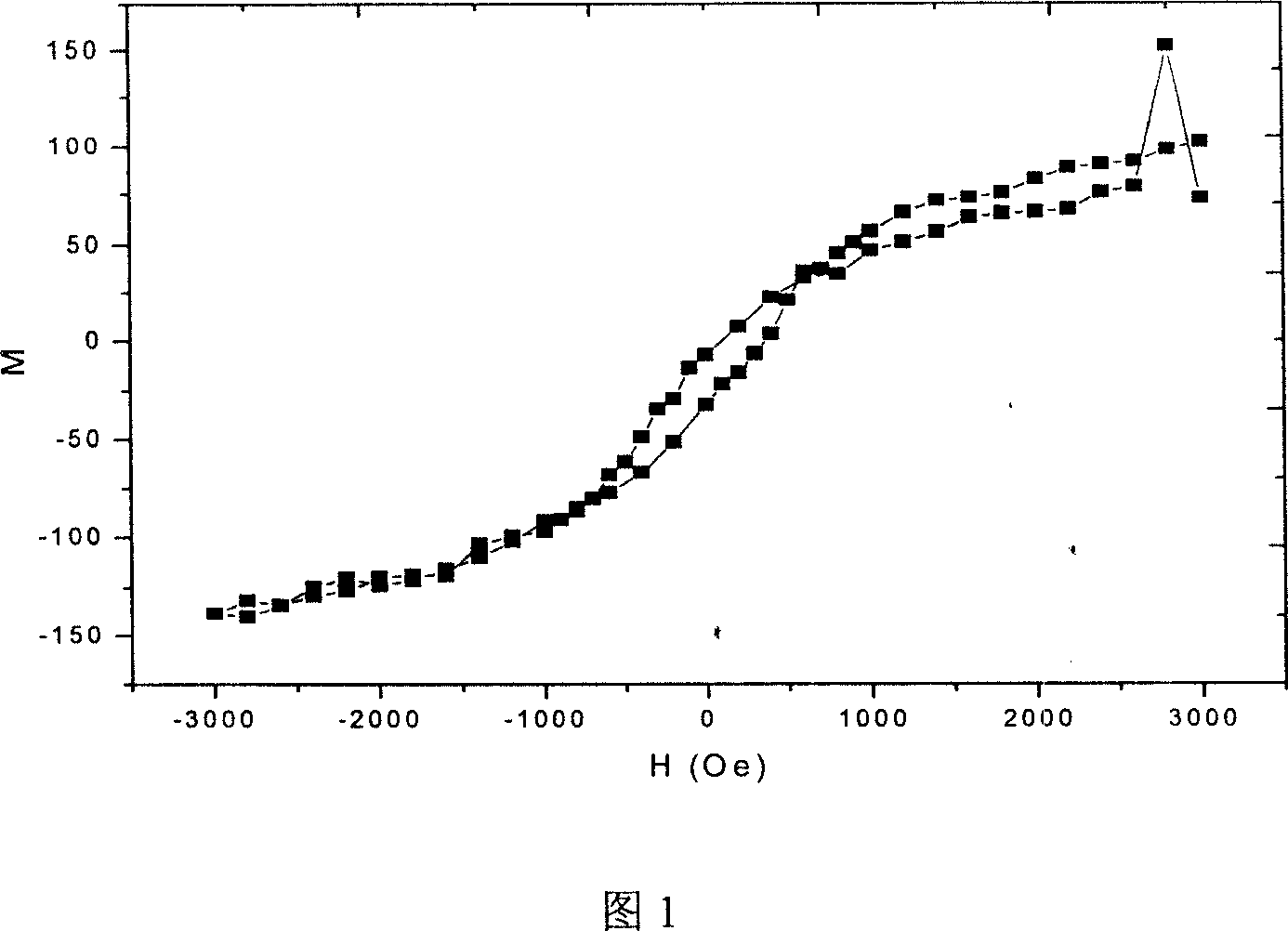

[0015] Put the glass substrate into absolute alcohol and clean it two to three times with an ultrasonic sounder. The substrate / TbFeCo (6nm) is prepared by computer-controlled multifunctional magnetron sputtering equipment, and the easy magnetization direction is difficult to be perpendicular to the film surface. As shown in Figure 1, the experimental curve of the sample at room temperature is given.

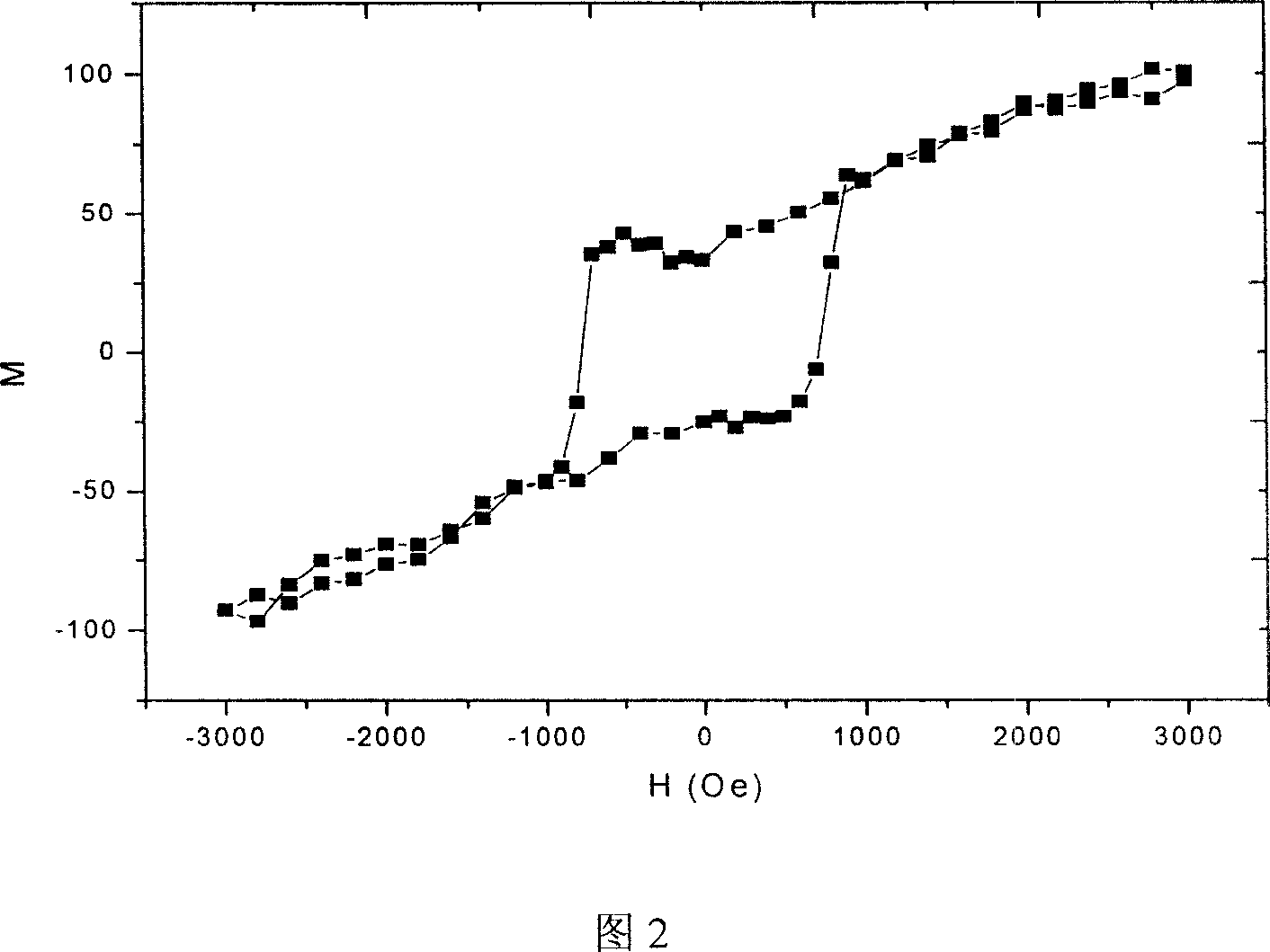

[0016] The substrate / MgO(0.8nm) / TbFeCo(6nm) is prepared by computer-controlled multifunctional magnetron sputtering equipment, the easy magnetization direction is perpendicular to the film surface, and the coercive force is obviously increased. As shown in Figure 2, the experimental curve of the sample at room temperature is given.

Embodiment 2

[0017] Embodiment two: component two TbFeCo

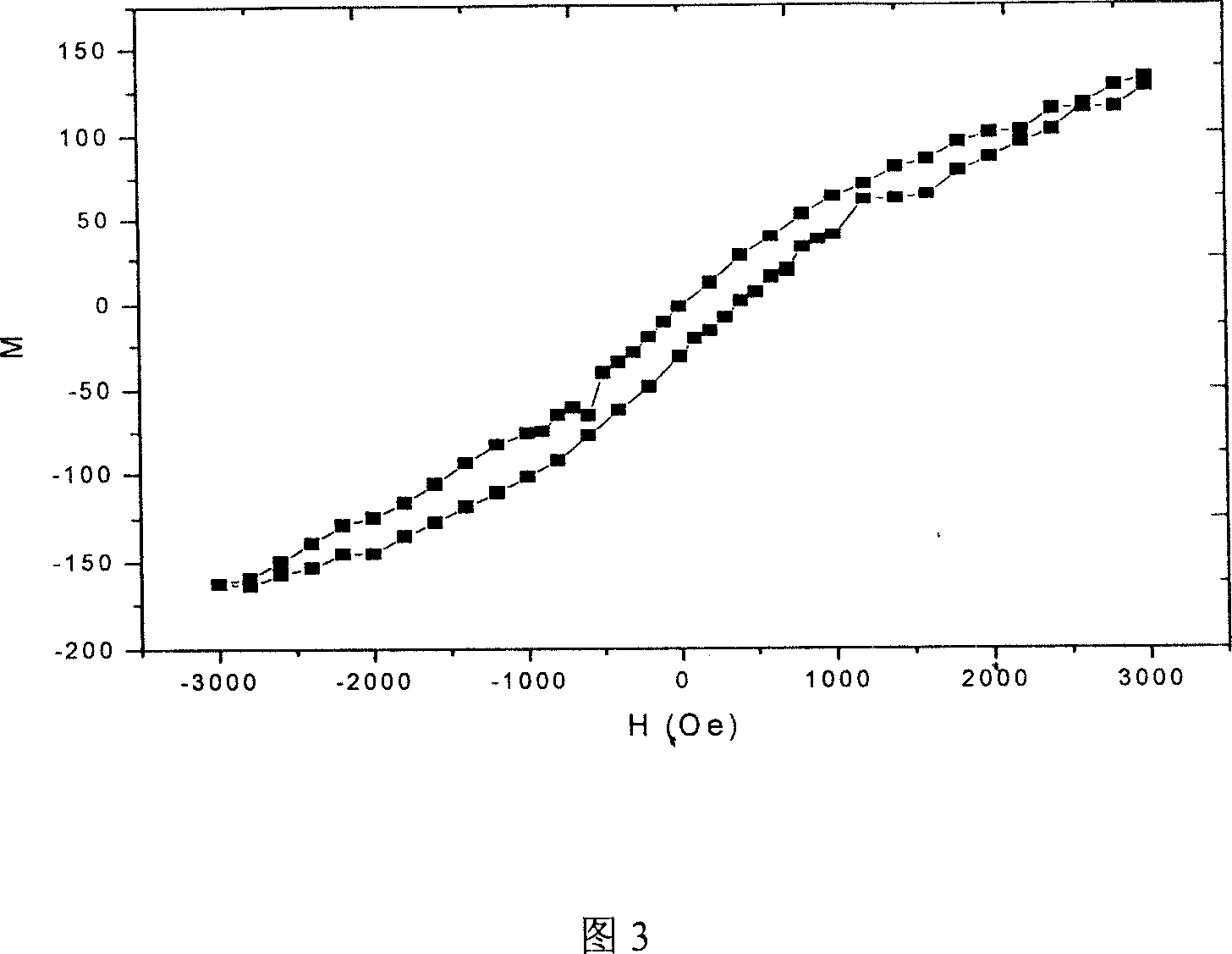

[0018] Carry out cleaning treatment (as embodiment 1) to glass substrate. The easy magnetization direction of the substrate / TbFeCo (9nm) is difficult to be perpendicular to the film surface by computer-controlled multifunctional magnetron sputtering equipment. As shown in Figure 3, the experimental curve of the sample at room temperature is given.

[0019] The substrate / MgO(2nm) / TbFeCo(9nm) easy magnetization direction is perpendicular to the film surface prepared by computer-controlled multifunctional magnetron sputtering equipment, and the coercive force increases greatly. The experimental curve of the sample at room temperature is shown in Figure 4.

Embodiment 3

[0020] Embodiment three: component three TbFeCo

[0021] Carry out cleaning treatment (as embodiment 1) to glass substrate. The substrate / TbFeCo (30nm) film surface perpendicular to the direction of easy magnetization was prepared by computer-controlled multifunctional magnetron sputtering equipment, and the film has coercive force. The experimental curve of the sample at room temperature is shown in Figure 5.

[0022] The substrate / MgO(1.2nm) / TbFeCo(30nm) is prepared by computer-controlled multifunctional magnetron sputtering equipment, and the film surface is perpendicular to the easy magnetization direction, and the coercive force increases. As shown in Figure 6, the experimental curve of the sample at room temperature is given.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com