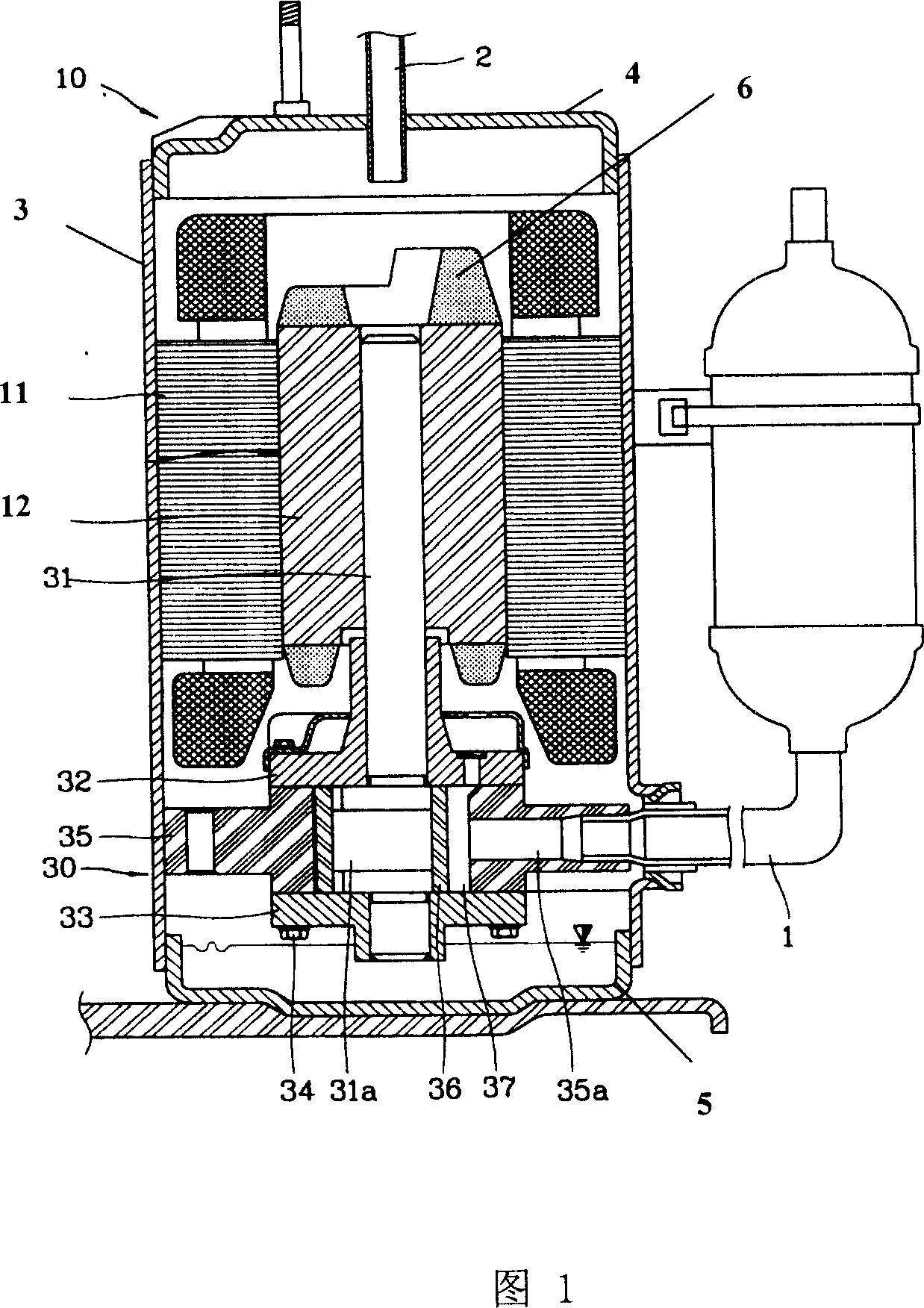

Upper bearing of rotary compressor

A rotary compressor and bearing technology, applied in rotary piston machinery, rotary piston/oscillating piston pump components, rotary piston pumps, etc., can solve problems such as high fluid noise and affect compressor efficiency, and achieve The effect of improving performance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

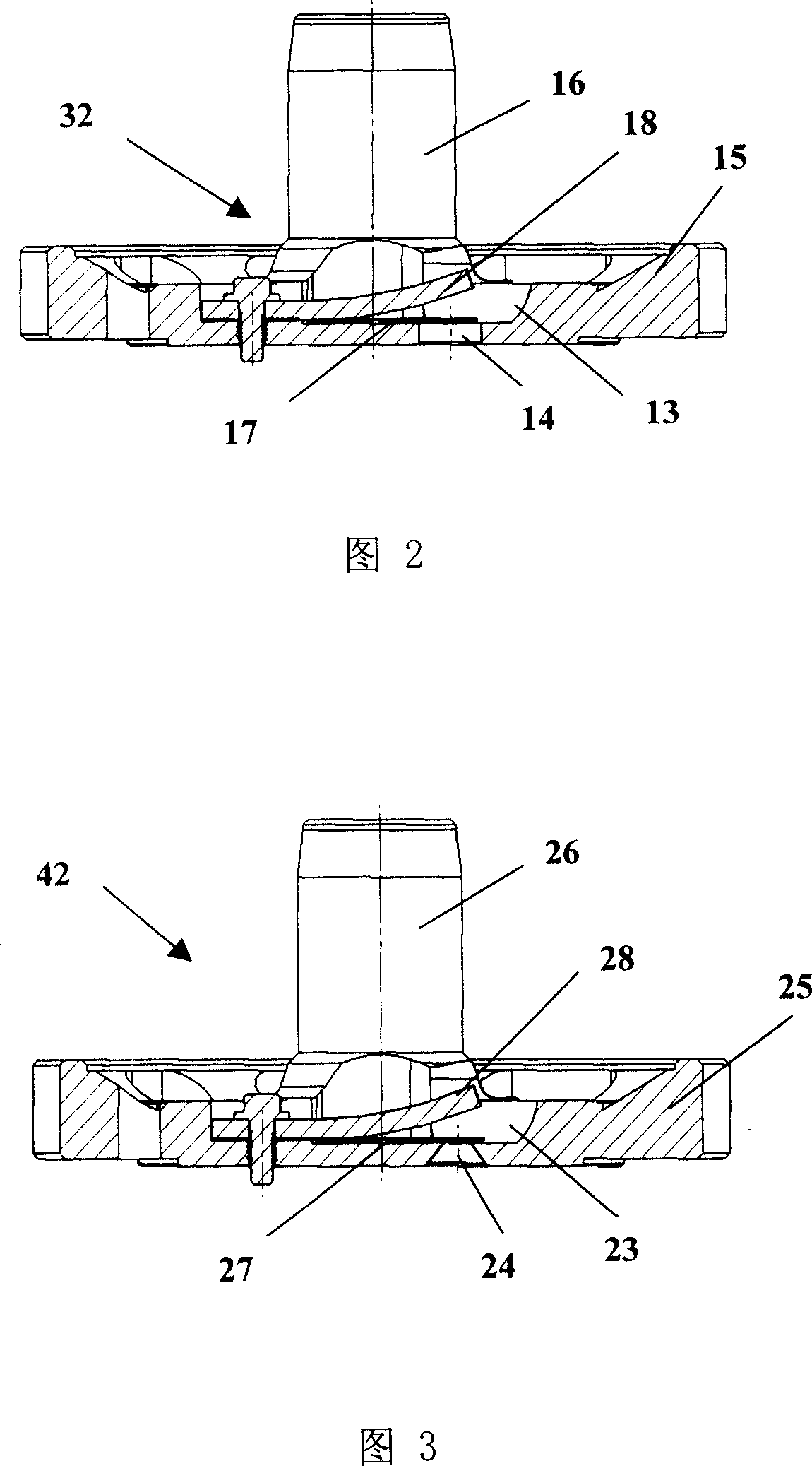

[0011] As shown in Figures 3 and 1, the upper bearing 42 of the rotary compressor provided by the present invention includes an elliptical mounting groove 23 formed on the top surface of the cylinder 35, and one side of the mounting groove 23 is A circular bearing housing 25 with an exhaust hole 24 formed therethrough; protruding upward from the center of the bearing housing 25 to be integrally formed, and a shaft sleeve 26 that can penetrate the central hole of the crankshaft 31 is formed at the center; mounted on the bearing housing 25 The inside of the upper mounting groove 23, and one end is fixed to the exhaust valve plate 27 on the bottom surface of the mounting groove 23 on the side opposite to the exhaust hole 24; and the upper part of the exhaust valve plate 27 in the mounting groove 23, one end The stopper 28 is fixed with the fixed end of the exhaust valve plate 27, and the other end is warped upwards, so as to limit the rising height of the free end of the exhaust valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com