A system for increasing the flue gas temperature at the inlet of denitrification under low load

A low-load, inlet technology, applied in the direction of emission prevention, combustion methods, lighting and heating equipment, etc., can solve the problems of air preheater clogging, catalyst activity reduction, affecting the safe and stable operation of the unit, etc., to adapt to changes in boiler load, The effect of changes in boiler load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention are described in further detail below: It should be emphasized that the embodiments of the present invention are illustrative rather than limiting, so the present invention is not limited to the embodiments described in the specific implementation methods. Other implementations obtained by those skilled in the art according to the technical solution of the present invention also belong to the protection scope of the present invention.

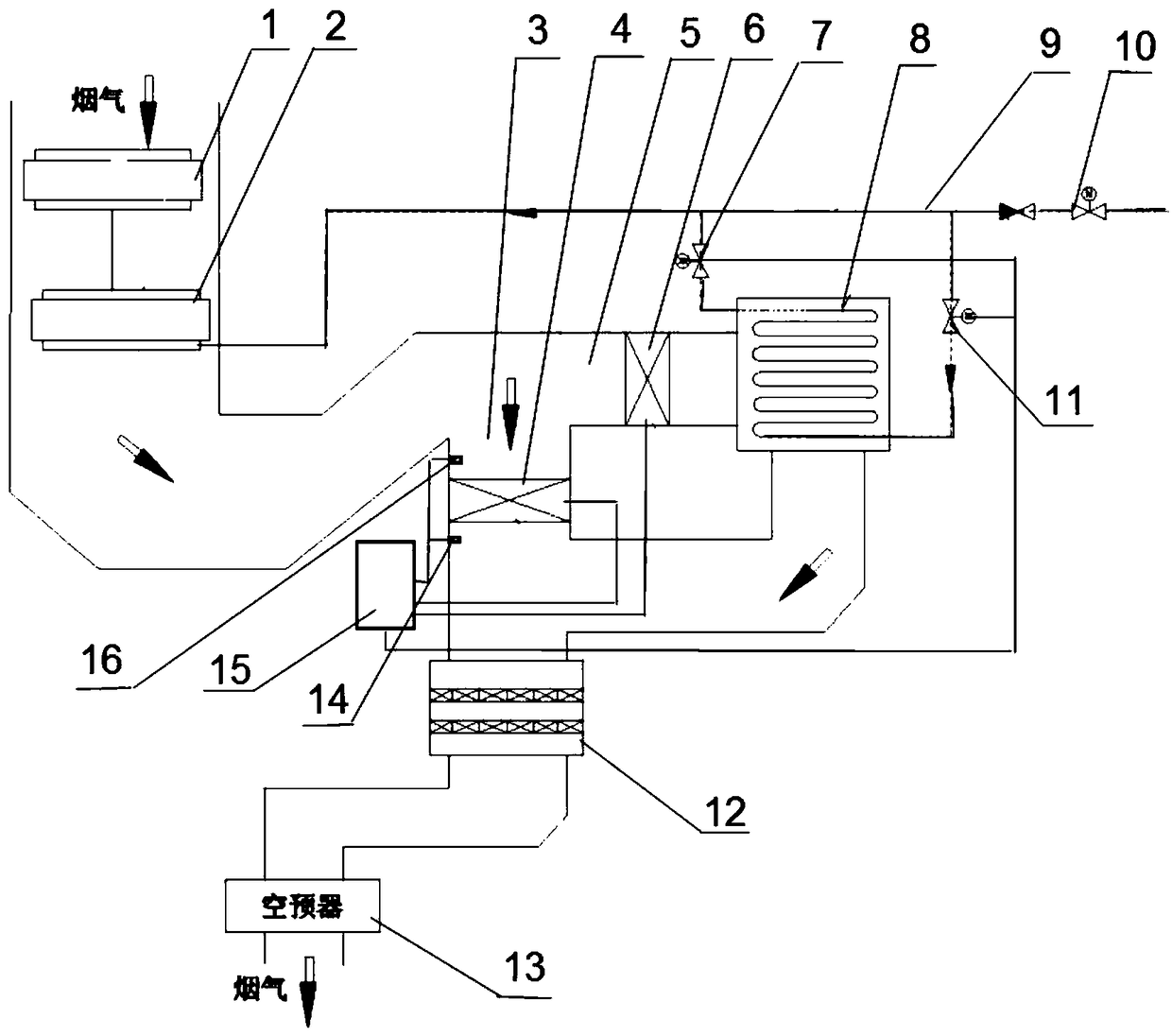

[0013] A system to increase the flue gas temperature at the denitrification inlet at low load, such as figure 1 As shown, it includes a low-temperature superheater 1, an economizer 2, and an air preheater 13 arranged in the boiler flue, and an SCR denitrification device 12 is arranged in the flue between the economizer and the air preheater. The innovation of the present invention Yes, the flue before the entrance of the SCR denitrification device is divided into the main flue 3 at the SCR entranc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com