Method for treating surface of copper-zinc-tin-sulfur-selenium film through plasma cleaning

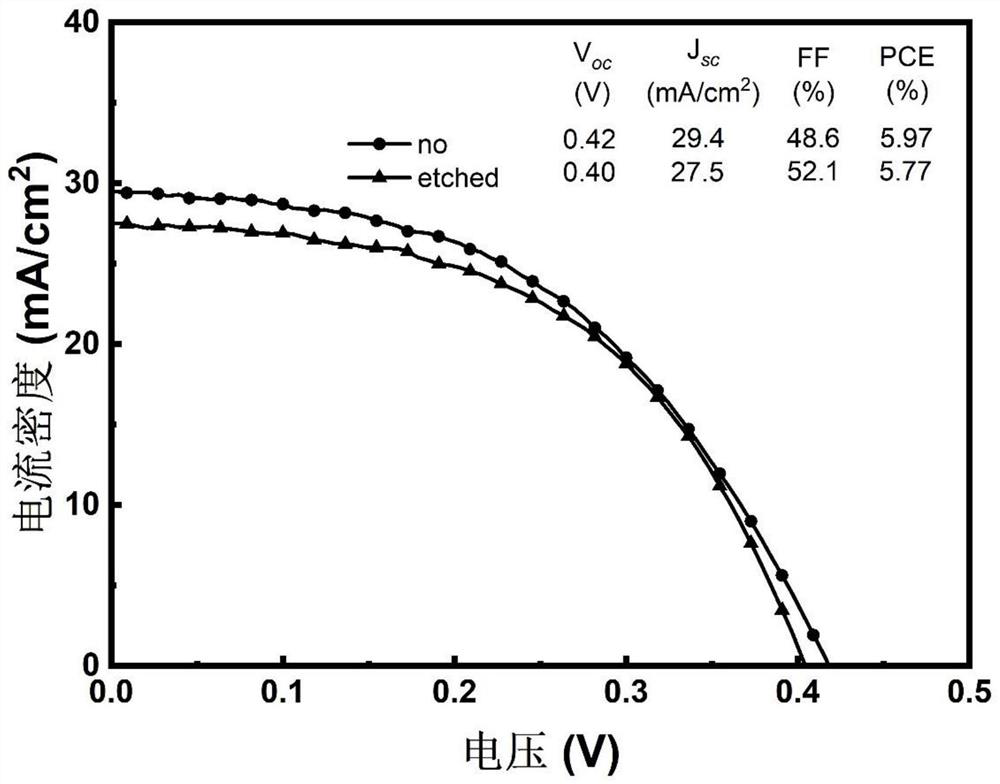

A copper-zinc-tin-sulfur-selenium, plasma cleaning technology, applied in cleaning methods and utensils, chemical instruments and methods, sustainable manufacturing/processing, etc. Effects of Density Reduction and Interfacial Contact Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for processing the surface of a copper-zinc-tin-sulfur-selenide film by plasma cleaning, comprising the following steps:

[0044] (1) Introduce Ar into the plasma cleaning chamber, the gas flow rate is 300mL / min, and the preparation pressure is 1×10 -2 Torr, clean the chamber with a power of 250W under no-load, and the no-load cleaning time is 10 minutes.

[0045] (2) Put the sample into the chamber, purge gas Ar:O 2 The volume ratio is 10:1, the total air flow is 300mL / min, the cleaning power is 150W, and the cleaning time is 30s.

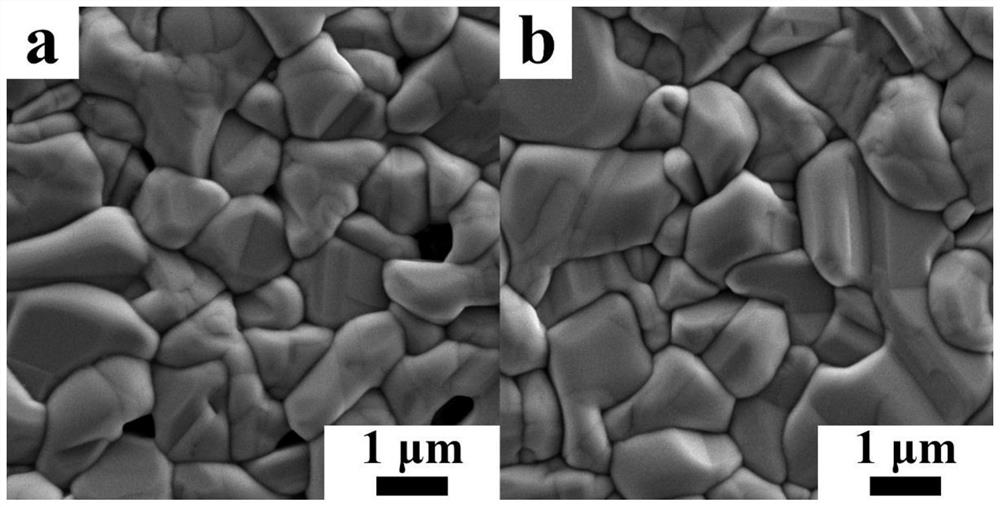

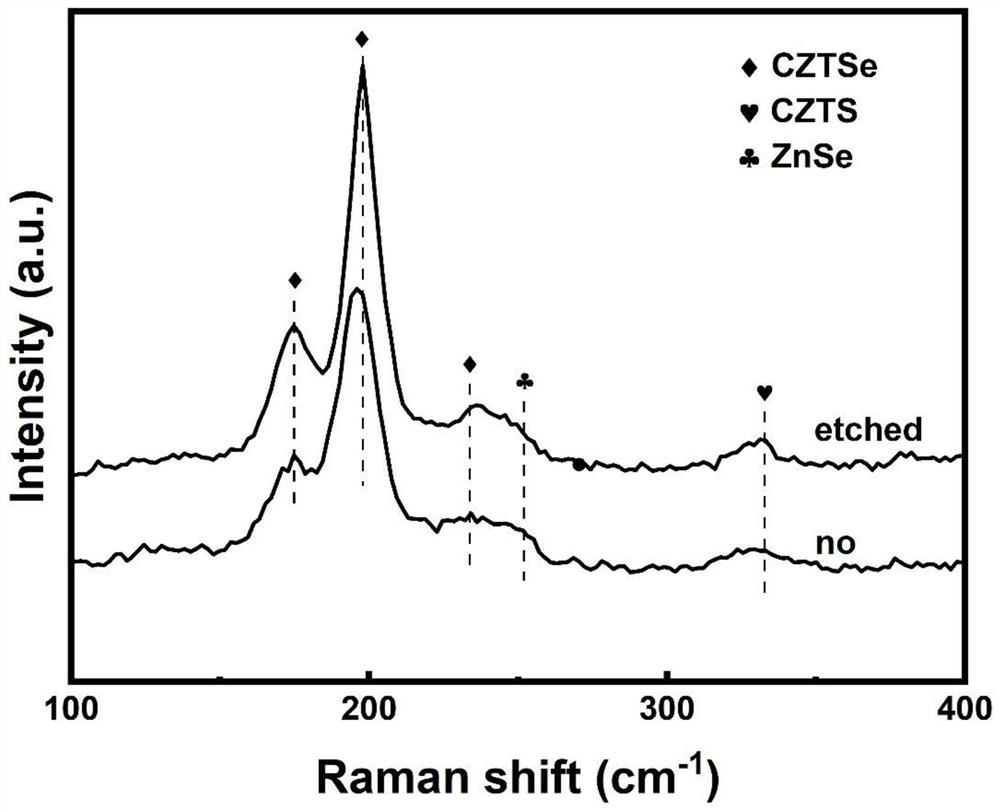

[0046] After cleaning the surface, turn off the air path and vacuum for a period of time, take out the copper-zinc-tin-sulfur-selenide film after surface treatment, and test that no new phases are formed on the surface by Raman test, and test that the large crystals on the surface are intact without obvious etching by SEM test crumbs.

Embodiment 2

[0048] A method for processing the surface of a copper-zinc-tin-sulfur-selenide film by plasma cleaning, comprising the following steps:

[0049] (1) Feed Ar into the plasma cleaning chamber, the gas flow rate is 200mL / min, and the preparation pressure is 1×10 -3 Torr, clean the chamber with no-load power of 150W, and the no-load cleaning time is 20min.

[0050] (2) Put the sample into the chamber, purge gas Ar:O 2 The volume ratio is 5:1, the total air flow is 350mL / min, the cleaning power is 200W, and the cleaning time is 20s.

[0051] After cleaning the surface, turn off the air path and vacuum for a period of time, take out the copper-zinc-tin-sulfur-selenide film after surface treatment, and test that no new phases are formed on the surface by Raman test, and test that the large crystals on the surface are intact without obvious etching by SEM test crumbs.

Embodiment 3

[0053] A method for processing the surface of a copper-zinc-tin-sulfur-selenide film by plasma cleaning, comprising the following steps:

[0054] (1) Introduce Ar into the plasma cleaning chamber, the gas flow rate is 400mL / min, and the preparation pressure is 1×10 0 Torr, clean the chamber with a power of 300W under no-load, and the no-load cleaning time is 5 minutes.

[0055] (2) Put the sample into the chamber, purge gas Ar:O 2 The volume ratio is 2:1, the total air flow is 400mL / min, the cleaning power is 250W, and the cleaning time is 10s.

[0056] After cleaning the surface, turn off the air path and vacuum for a period of time, take out the copper-zinc-tin-sulfur-selenide film after surface treatment, and test that no new phases are formed on the surface by Raman test, and test that the large crystals on the surface are intact without obvious etching by SEM test crumbs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com