Plane mirror spliced heavy-calibre grating pulse compressor

A large-aperture grating and pulse compression technology, which is applied in diffraction gratings, instruments, optics, etc., can solve the problems of high cost and difficulty, and achieve the effects of easy use, low adjustment difficulty, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

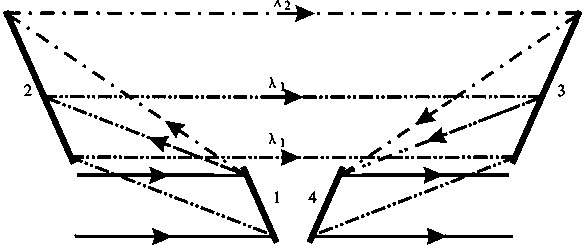

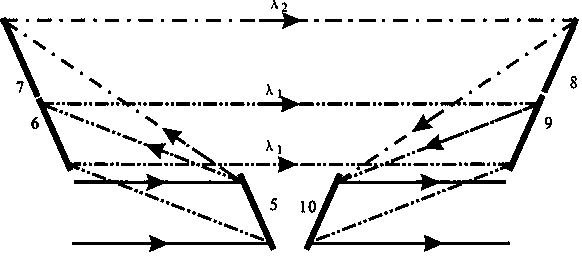

[0025] see Figure 4 , Figure 4 It is a schematic diagram of the structure of the large-diameter grating pulse compressor spliced with a plane mirror of the present invention. It can be seen from the figure that the large-diameter grating pulse compressor of the present invention is composed of a first grating 11, a second grating 12, a first plane mirror 13, and a third grating. 15. The fourth grating 16 and the second plane mirror 14, the positional relationship of the above components is as follows:

[0026] The grating surfaces of the first grating 11 and the second grating 12 are parallel to each other, and the first plane mirror 13 is perpendicular to the second grating 12 and form a first combination. The grating surfaces of the third grating 15 and the fourth gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com