Transformer and its producing method

A transformer, vertical technology, applied in the field of transformers, can solve the problems of high manufacturing cost and assembly cost, low transformer coupling degree, complex coil structure, etc., and achieve the effects of low manufacturing cost, cost reduction, and increase of effective cross-sectional area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An embodiment of the present invention will be described below with reference to the drawings.

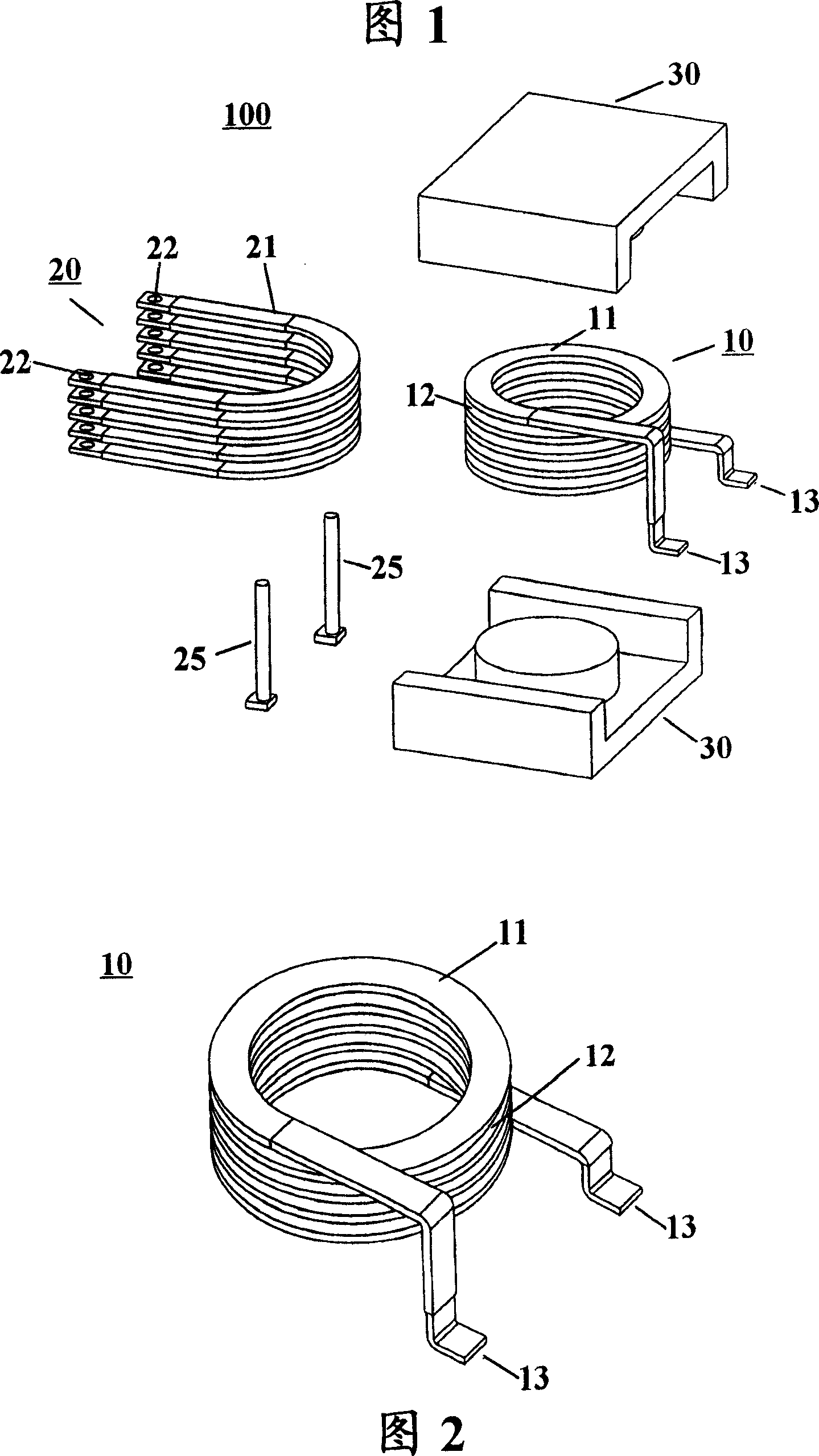

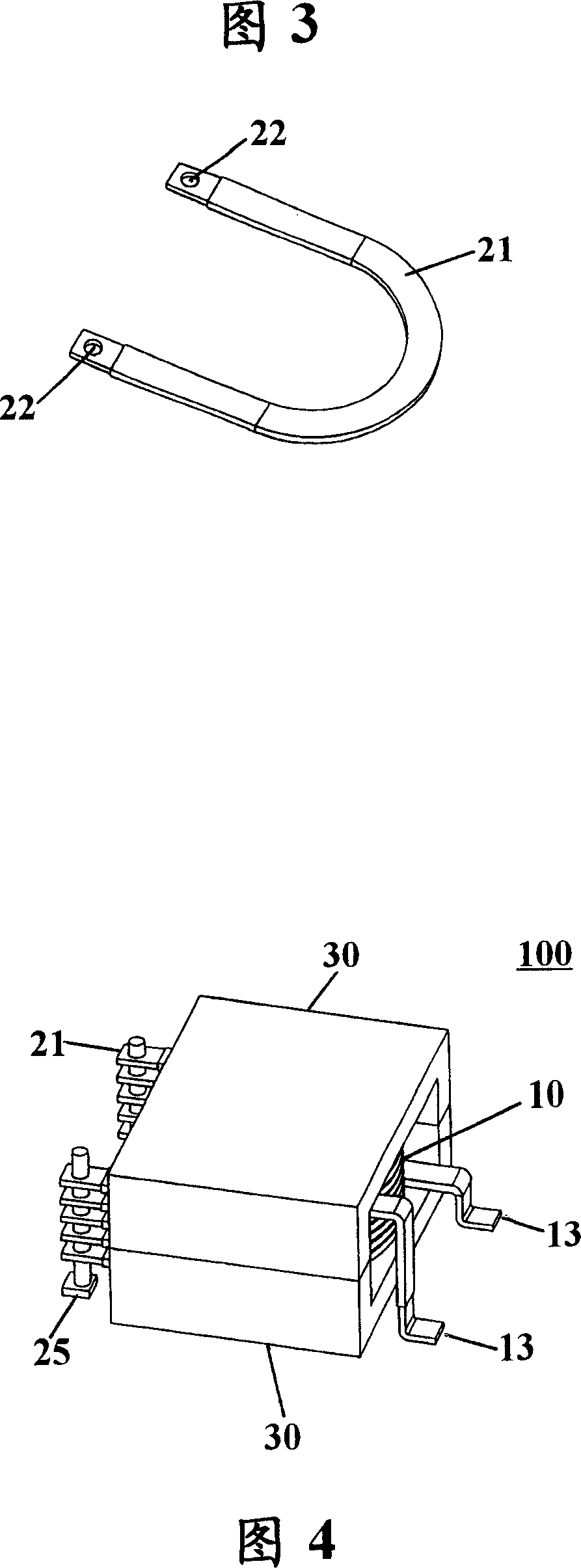

[0022] As shown in FIG. 1 , the transformer 100 of the present invention includes a primary coil 10 , a secondary coil 20 and a pair of magnetic cores 30 . The magnetic core 30 is a ferrite core commonly used in the field, which will not be described in detail herein.

[0023] As shown in Figure 2, the primary coil 10 is formed by helically winding a flat conductor 11 around an axis (not shown) perpendicular to the plane of the conductor, and there are Certain gaps12. In the description herein, the direction in the plane where the flat conductor is located is referred to as the horizontal direction, and the direction perpendicular thereto, that is, the direction in which the above-mentioned axis is located, is referred to as the vertical direction. Both ends of the primary coil 10 protrude outwards to form connection terminals 13 . The primary coil can be dipped in varnis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com