Electrostatic discharging protection circuit triggered by lining-bottom

An electrostatic discharge protection and substrate technology, which is applied to circuits, electrical components, and electrical solid devices, etc., and can solve problems such as uneven opening and large bulk resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

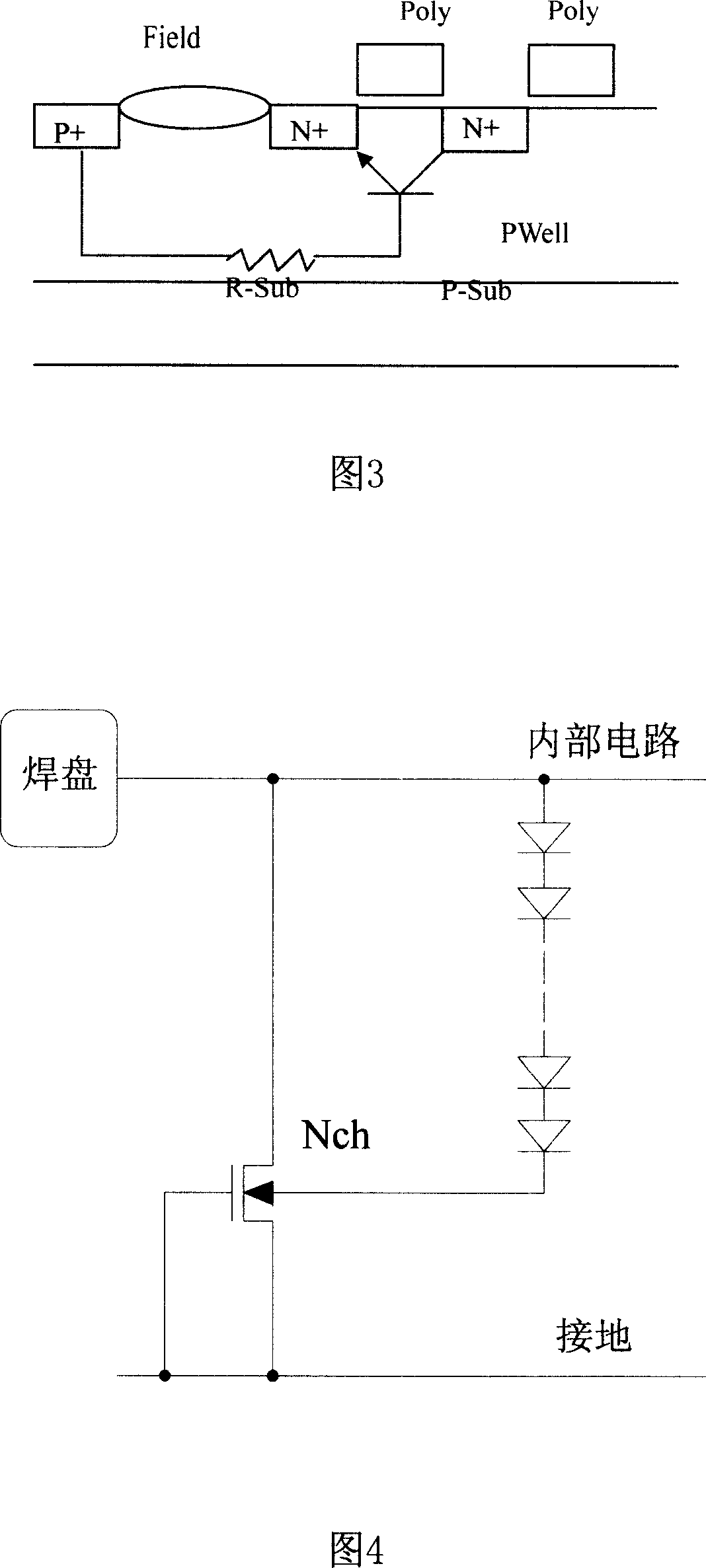

[0011] The circuit provided by the present invention is shown in Figure 4. In the traditional structure using GGNMOS as an ESD protection circuit, a voltage-dividing diode string is added, and the anodes and cathodes of every two adjacent diodes in the diode string are connected end to end. The diode string is placed between the previous stage of the internal circuit and the N-type metal oxide buffer (Nch Buffer) transistor substrate (bulk), the anode of the first diode is connected to the previous stage of the internal circuit, and the cathode of the tail diode is connected to the Nch Buffer The substrates of the transistors are connected, and the number of stages of the diode string is designed to make its turn-on voltage larger than the normal voltage operating range, but slightly smaller than the breakdown voltage of the Nch Buffer transistor. If the norm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com