Absorbency substance and manufacturing method thereof

A technology for absorbent articles, which is applied in the field of absorbent articles and their manufacture, can solve the problems of extreme reduction in cushioning performance, insufficient shape retention, and small bumps, etc., to eliminate surface residue, maintain quality style, and high cushioning performance Effect

Active Publication Date: 2007-06-20

DAIO PAPER CORP

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, although the fiber part of the raised part can ensure the raised amount in a dry state, when it becomes a wet state, the fiber is naturally compressed (sluggish state), the raised amount is reduced, and the cushioning performance is extremely reduced, and the shape retention of unevenness is insufficient. And other issues

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

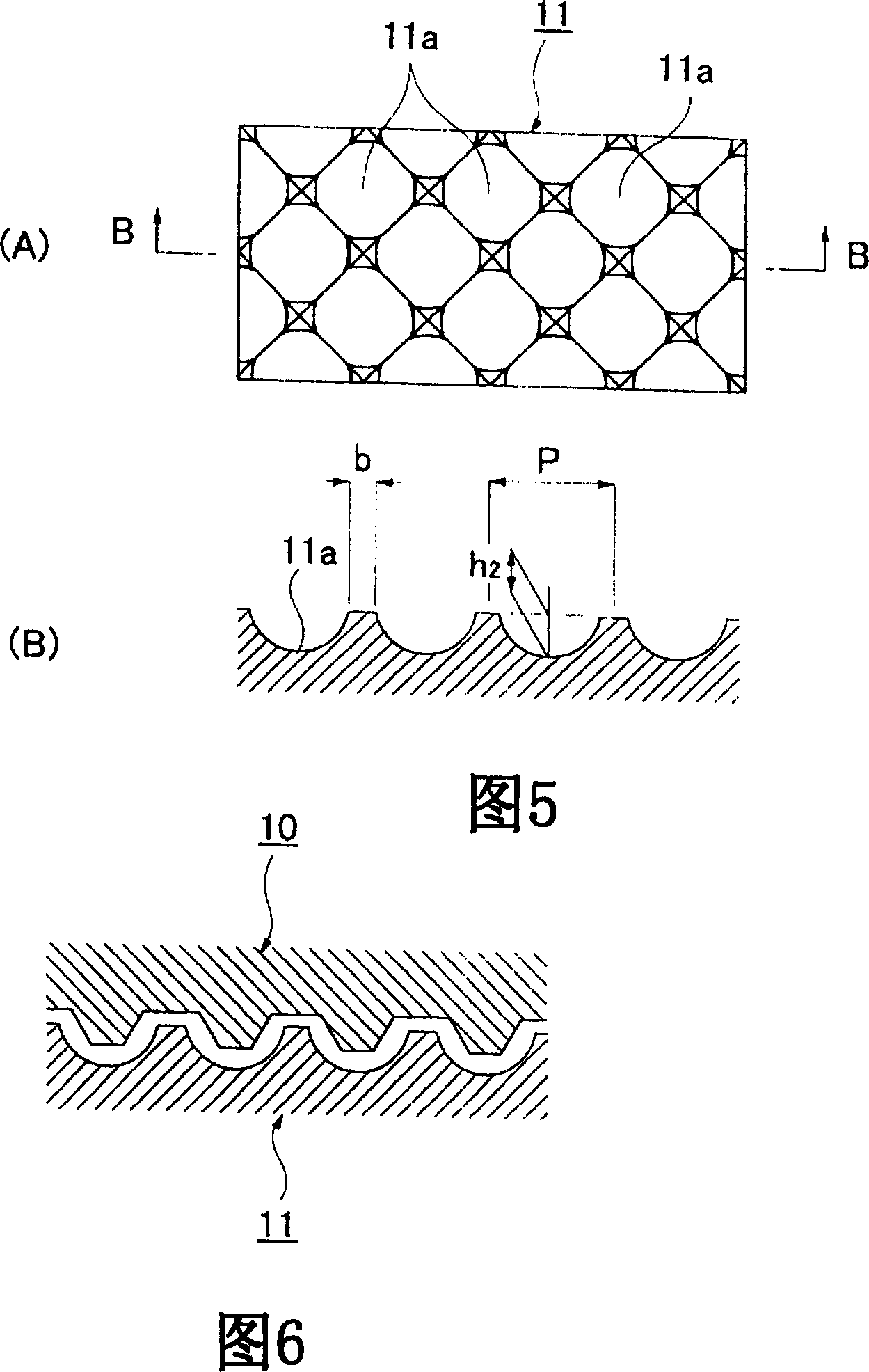

[0072] (1) Cushioning test when the interval P on the concave side is different

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

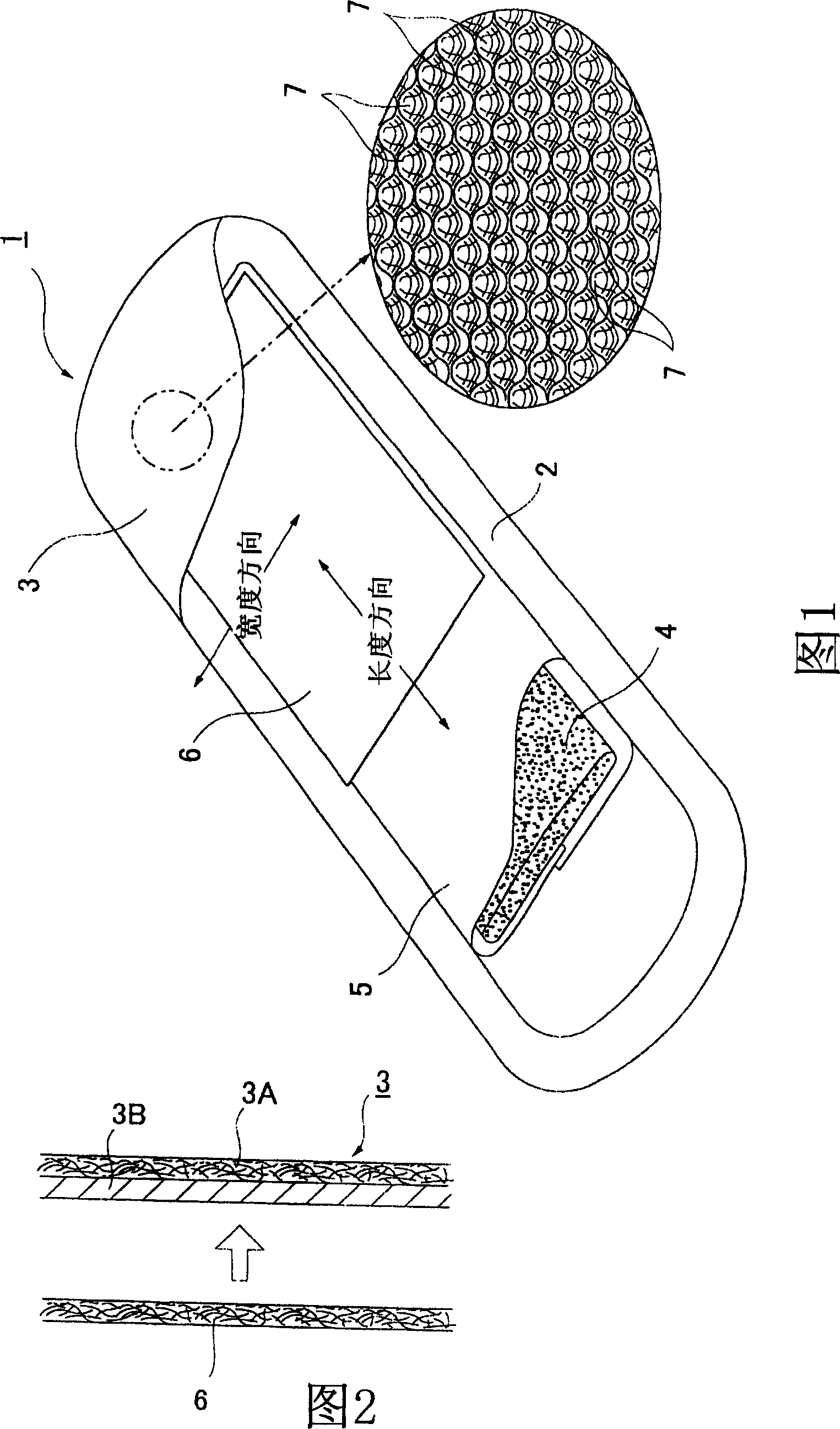

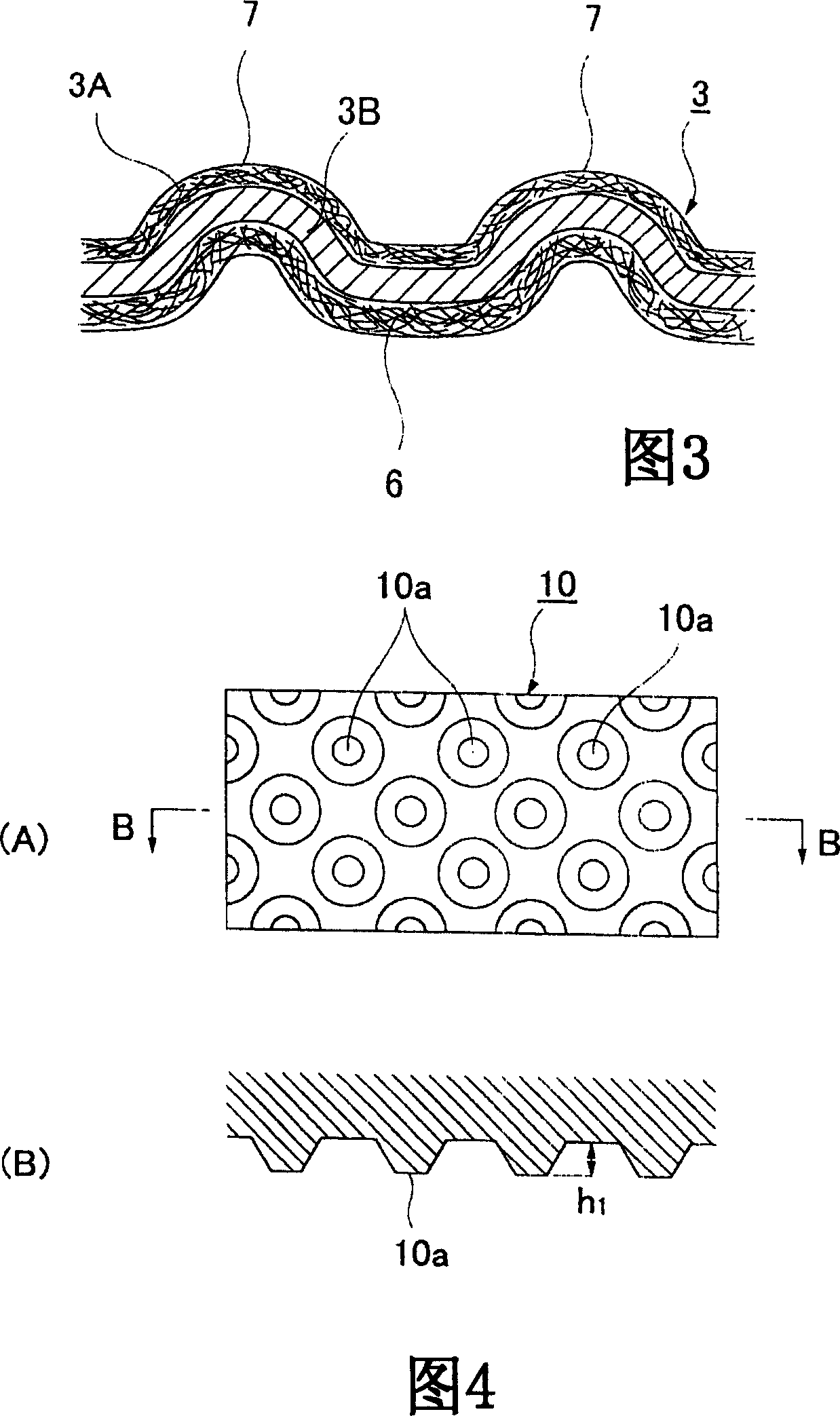

The invention provides an absorbable article and a method for manufacturing the same, which has strong felling of stereo perception, high shock-absorbing capacity, capable of minimizing area contacting with skin, and can maintain concavo convex embossing shape all the time. A surface sheet (3) is a multilayer sheet having two layer which comprises at least a non-woven favrics layer (3A) constituting skin contacting layer and a plastic film layer (3B) stacking on a non-skin contacting layer side of the non-woven favrics layer (3A), and the plastic film layer (3B) is formed by materials having the melting point lower than the non-woven favrics layer. Concavo convex shape embossing and a plurality of tapping treatments are implemented on a compounding sheet comprising the surface sheet (3) and a second non-woven favrics sheet (6) formed by materials having the melting point lower than the non-woven favrics layer (3A) which is bonding to the inner side fo the surface sheet (3), in a heating condition not less than the melting point of the plastic film layer (3B) and the non-woven favrics sheet (6), and less than the melting point of the non-woven favrics layer (3A).

Description

technical field [0001] The present invention relates to an absorbent article using a surface sheet that is rich in three-dimensionality and has high cushioning properties and eliminates skin troubles by reducing the contact area with the skin, and a method for manufacturing the same, and the surface sheet is embossed in a concave-convex shape Excellent shape retention. Background technique [0002] Conventionally, as surface materials of absorbent articles, materials with appropriate embossed patterns for the various purposes of reducing the contact area with the skin to suppress wetness, or obtaining texture and improving tactile sensation have been provided on the market. Examples of such materials include the techniques of the following Patent Documents 1 to 5 and the like. [0003] Patent Document 1 below discloses an absorbent article using, as a top sheet, a nonwoven fabric having a plurality of openings, on which a plurality of ridges and grooves are alternately arra...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A61F13/15A61F5/44

Inventor 铃木理惠

Owner DAIO PAPER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com