Calcium aluminate cement

A calcium aluminate cement and cement technology, applied in the field of chemical building materials, can solve problems such as being unsuitable for rotary kilns, and achieve the effects of improving cement quality, stable quality, and reliable quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

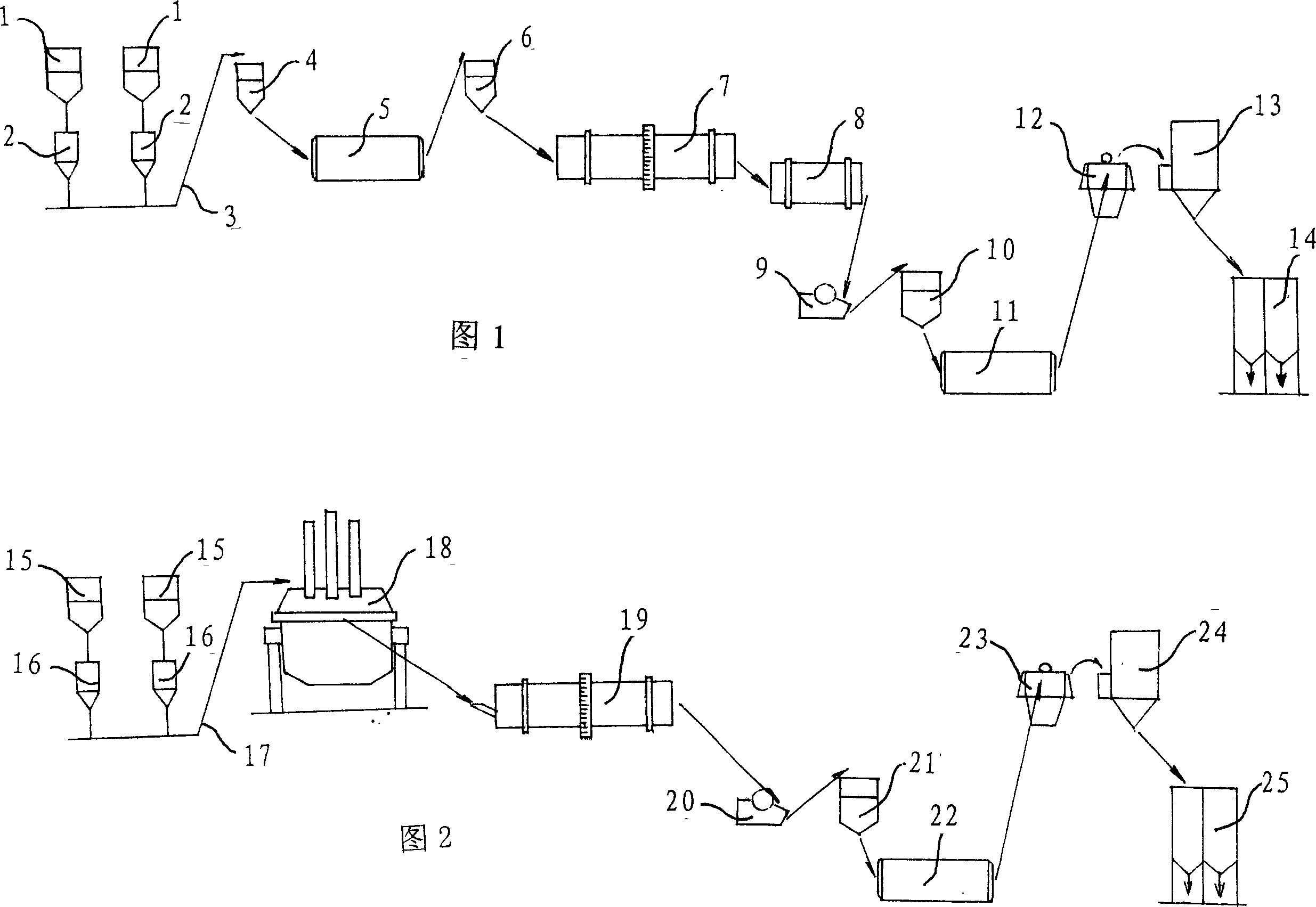

[0026] to AL 2 o 3 The ratio of CaO is 1.65. Weigh the raw materials of bauxite and limestone, and manufacture them according to the rotary kiln sintering process shown in Figure 1. The specific surface area of the prepared cement is 3950cm 2 / g.

[0027] After performance test: initial setting time 3 hours and 34 minutes

[0028] Final setting time 4 hours and 20 minutes

[0029] One day compressive strength 70.5Mpa

[0030] Make self-leveling floor material

[0031] 30 seconds self flow value 400mm

Embodiment 2

[0033] to AL 2 o 3 The ratio of CaO is 1.58. Weigh the raw materials of bauxite and limestone, and manufacture them according to the rotary kiln sintering process shown in Figure 1. The specific surface area of the prepared cement is 3550cm 2 / g.

[0034] After performance test: initial setting time 2 hours

[0035] Final setting time 2 hours and 25 minutes

[0036] One day compressive strength 56.2Mpa

[0037] Make self-leveling floor material

[0038] 30 seconds self flow value 400mm

Embodiment 3

[0040] to AL 2 o 3 The ratio of CaO is 1.51. Weigh the raw materials bauxite and limestone, and manufacture them according to the electric arc furnace melting process process shown in Figure 2. The specific surface area of the prepared cement is 4000cm 2 / g.

[0041] After performance test: initial setting time 3 hours and 30 minutes

[0042] Final setting time 4 hours 04 minutes

[0043] One day compressive strength 76.4Mpa

[0044] Make self-leveling ground

[0045] 30 seconds self flow value 400mm

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com