Wind-driven power generator and system

A generator and wind wheel technology, applied in wind generator components, wind power generation, wind turbines, etc., can solve the problem of high cost, achieve the effects of small energy loss, reduce manufacturing cost, and improve power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

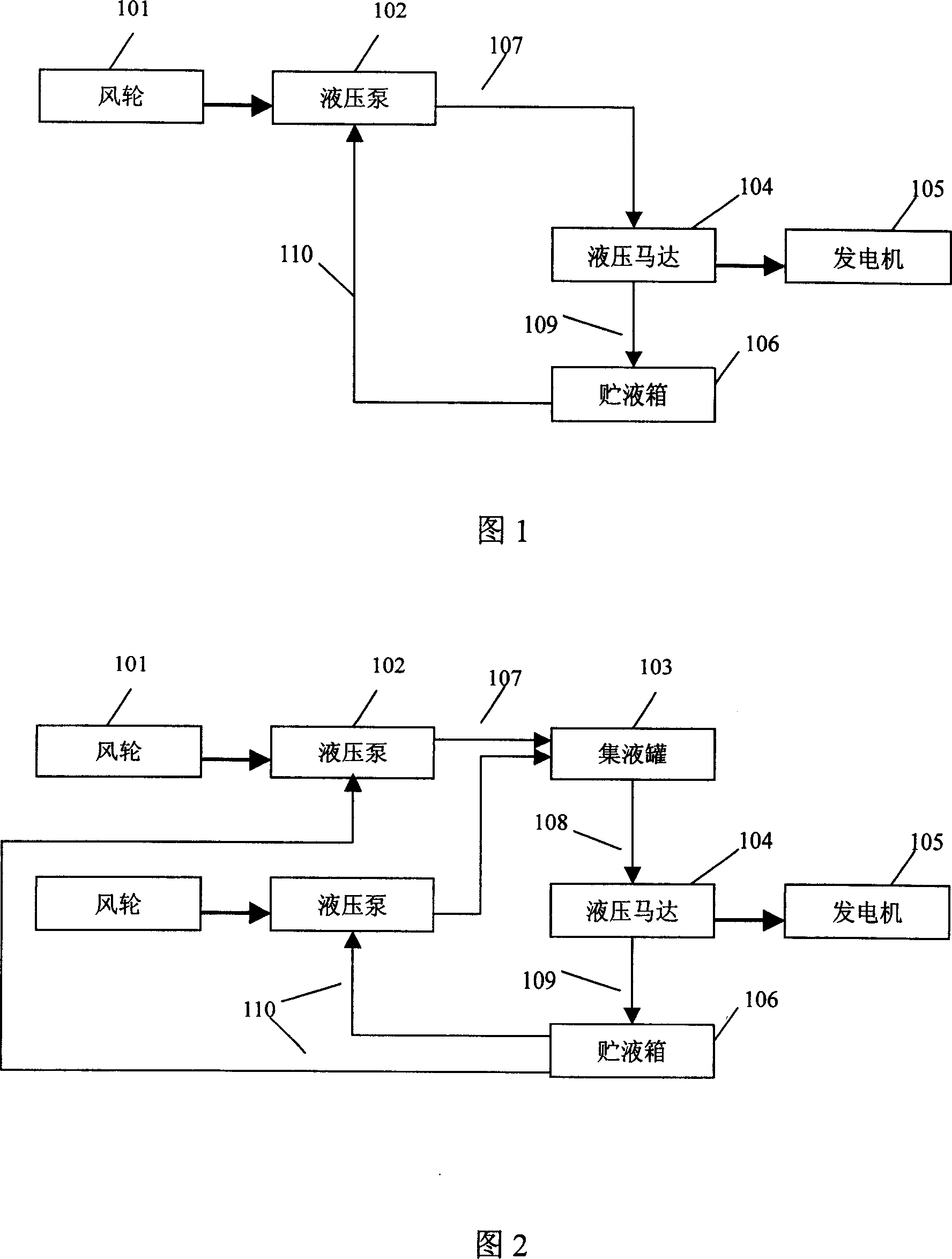

[0026] In a preferred embodiment of the present invention, the principle of the wind power generation device is shown in Fig. 1, the thick line arrows in the figure represent mechanical shaft transmission, and the thin line arrows represent liquid transmission.

[0027] It can be unloaded from FIG. 1 , the wind power generation device includes a wind wheel 101 , a hydraulic pump 102 , a hydraulic motor 104 , a generator 105 , a liquid storage tank 106 , and three liquid delivery pipes 107 , 109 , 110 . During the specific implementation, of course, towers, offset devices, control circuits, etc. are also included, but only the parts related to the working principle of the wind power generation device will be introduced here.

[0028] Wherein, the wind wheel 101 is used for converting wind energy into rotational mechanical energy. The working principle and structure of the wind wheel are mature prior art. When the wind blows, it can be driven by the wind to rotate, and its rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com