Electric oven

A technology for electric ovens and electrical component rooms, which is applied in the field of electric ovens, and can solve problems such as temperature rise in electrical component rooms, food heating efficiency reduction, thermal energy gap leakage, etc., to achieve the effect of preventing heat loss and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. However, this invention may be embodied in many different forms and should not be construed as limited to only set forth embodiments; Rather, these embodiments are provided so that this disclosure will be more detailed and complete, and enable those skilled in the art fully understand the principles of the invention.

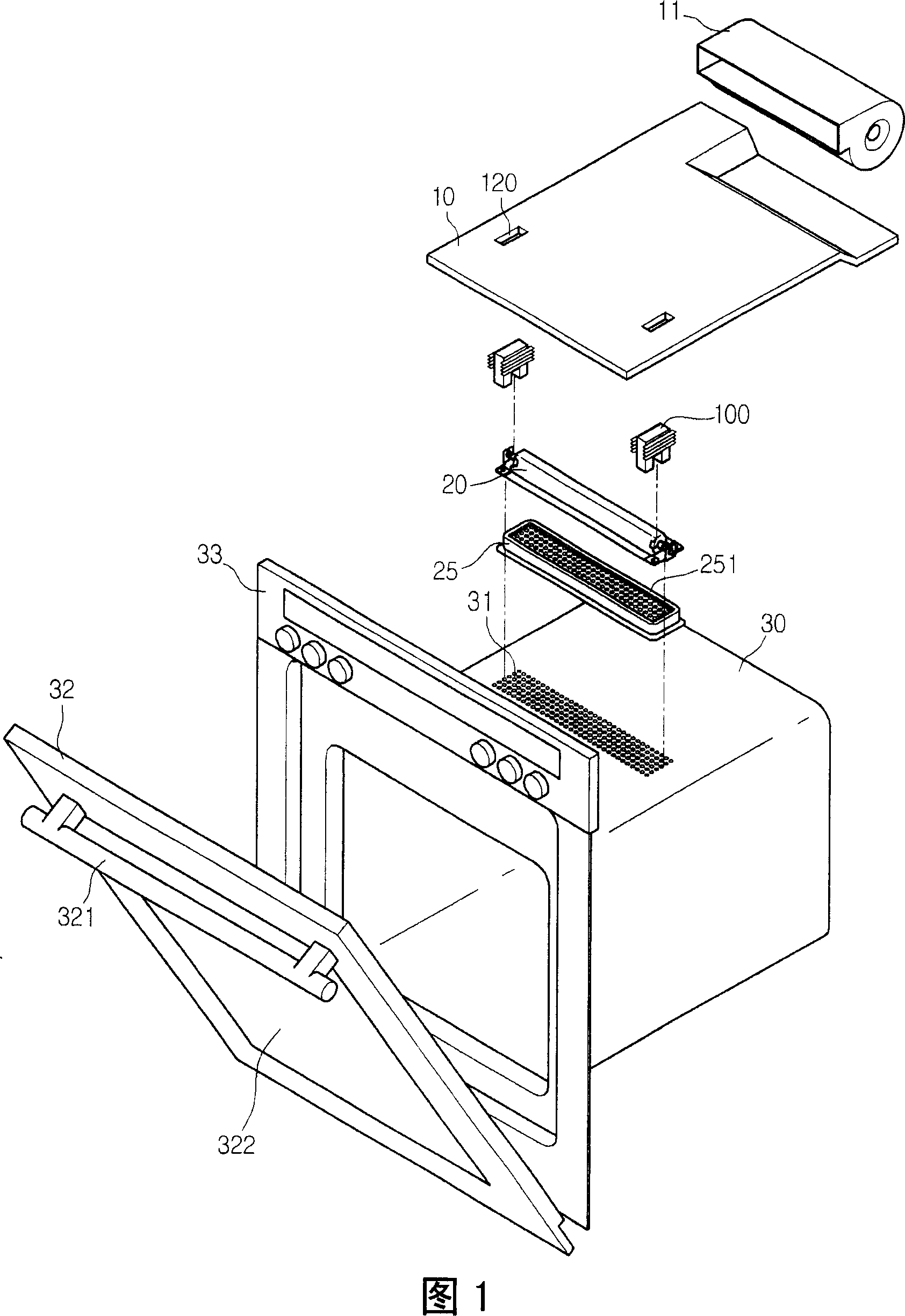

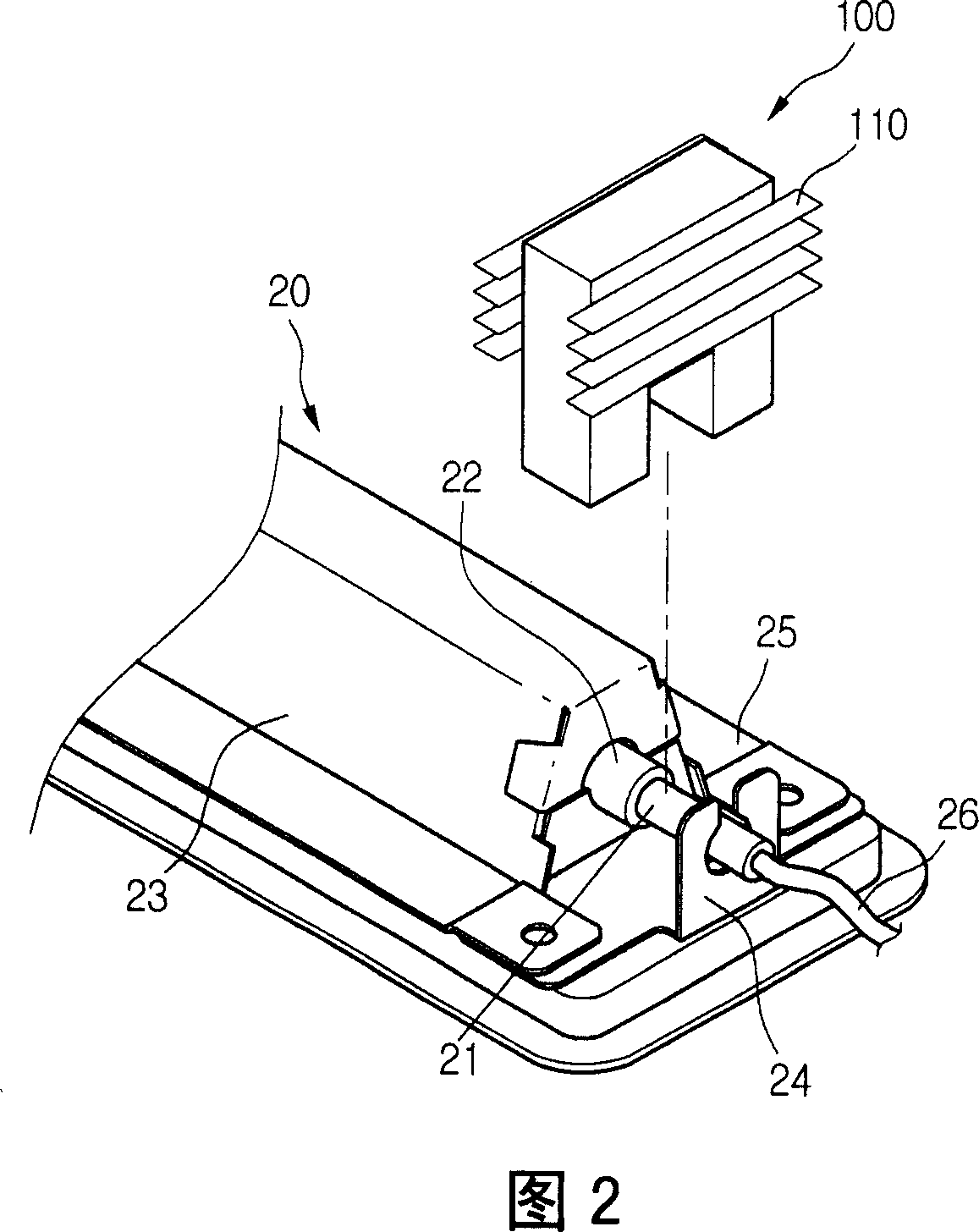

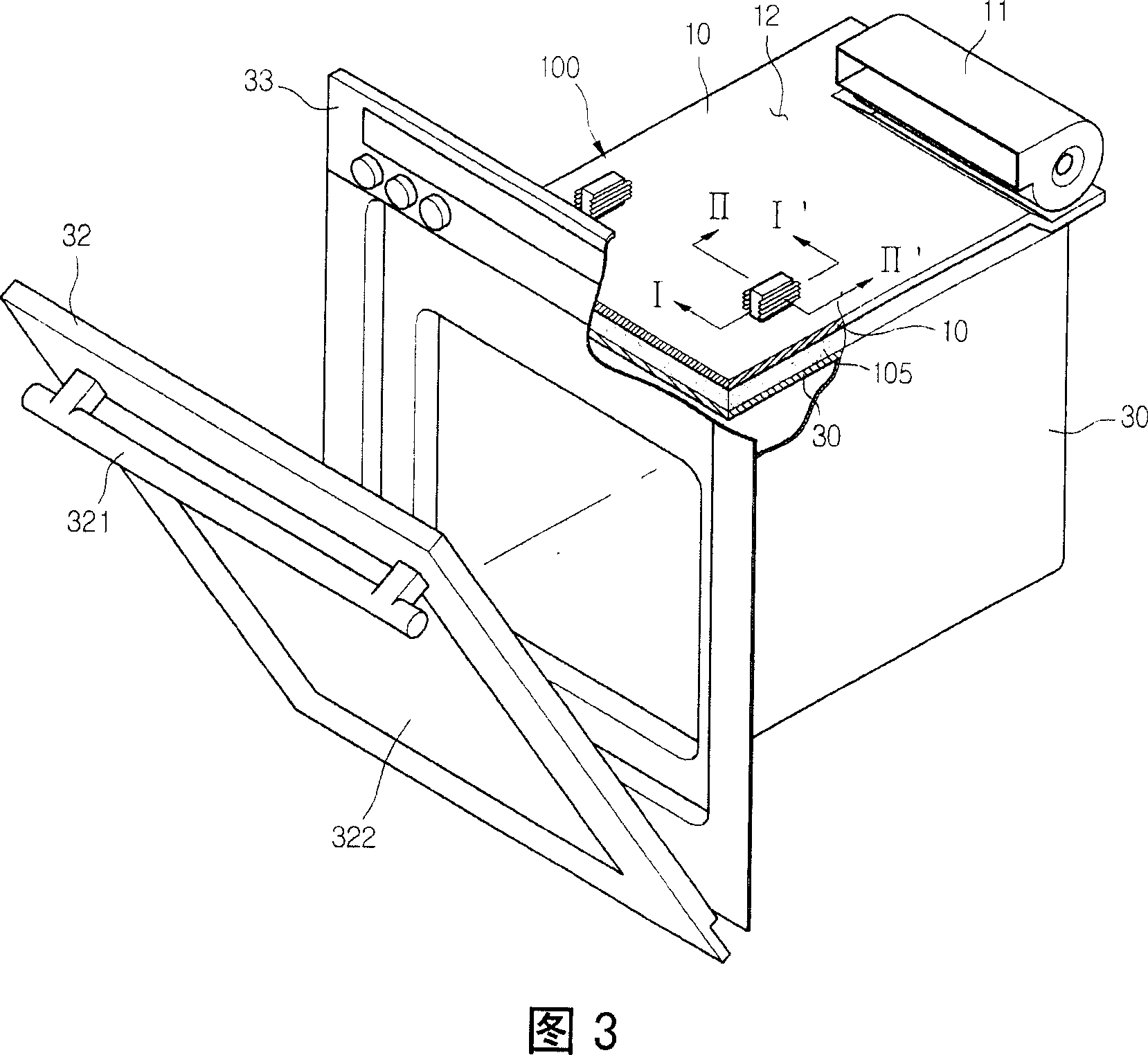

[0029] Fig. 1 is an exploded perspective view of an upper structure of an electric oven cavity according to an embodiment of the present invention, and Fig. 2 is a partial perspective view of a halogen heater according to an embodiment of the present invention.

[0030] 1 and 2, an electric oven according to one embodiment of the present invention includes: a cavity 30, which forms a cooking chamber; a light wave generator 20, which is installed on the top of the cavity 30; a partition 10, which covers the A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com