Light-guiding board, negative-light mould set and liquid-crystal display device

A technology for backlight modules and liquid crystal display panels, applied in optics, nonlinear optics, diffusing elements, etc., can solve the problems of complex frame structure design, and achieve the effect of speeding up the design and manufacturing process and simplifying the structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

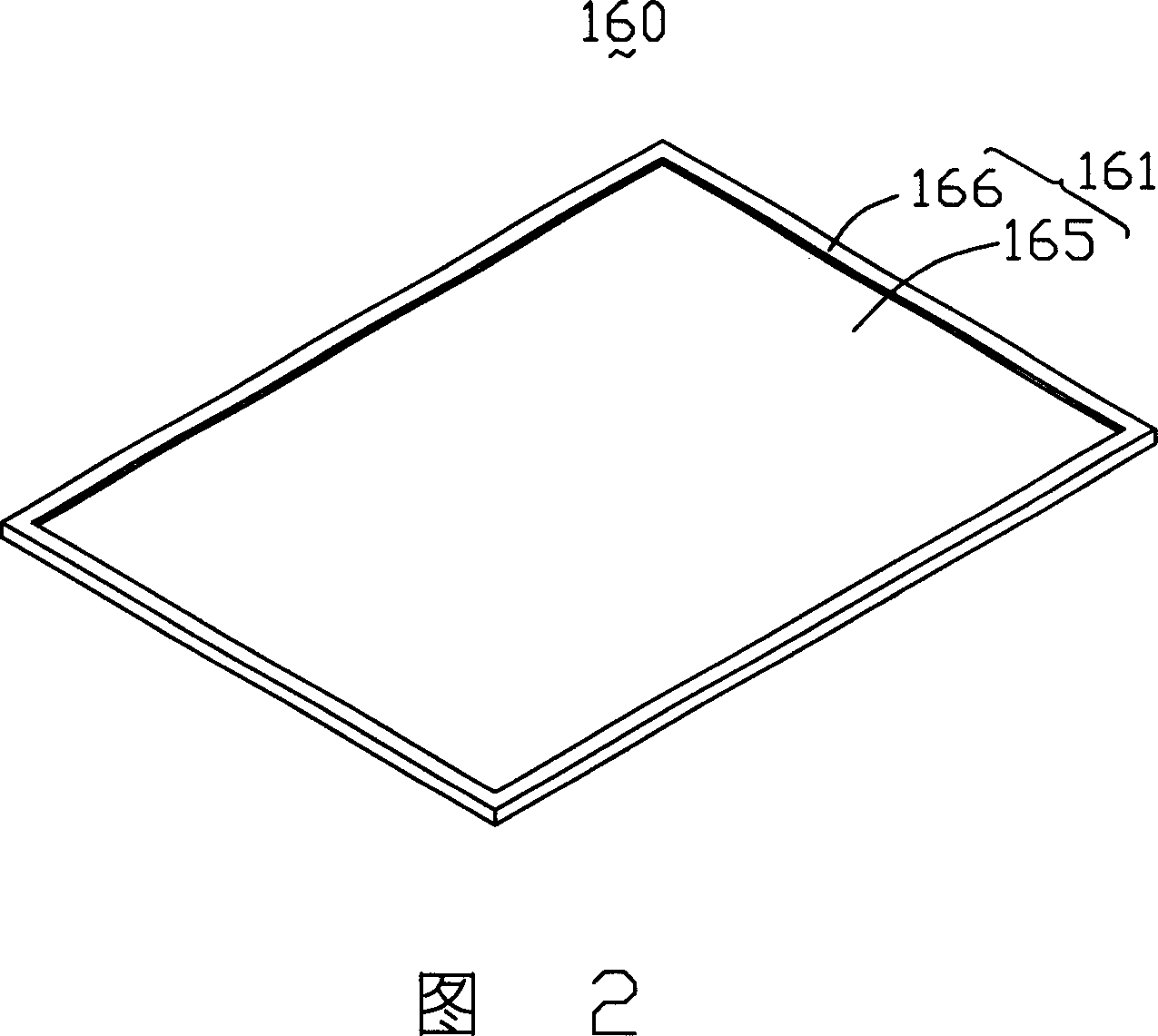

[0022] Please refer to FIG. 2 . FIG. 2 is a schematic structural diagram of the first embodiment of the light guide plate of the present invention. The light guide plate 160 is a flat plate with a light emitting surface 161 . The light emitting surface 161 is provided with a recessed portion 165 and a flange 166 surrounding the recessed portion 165 , and the recessed portion 165 can be produced together when manufacturing the light guide plate 160 by injection molding. The light-emitting surface of the light guide plate 160 is provided with a recessed portion 165 for accommodating the optical film used in the backlight module such as the diffusion film and the enhancement film, and the flange 166 can be used for tightly enclosing the optical film to achieve precise positioning of the optical film. purpose of the film.

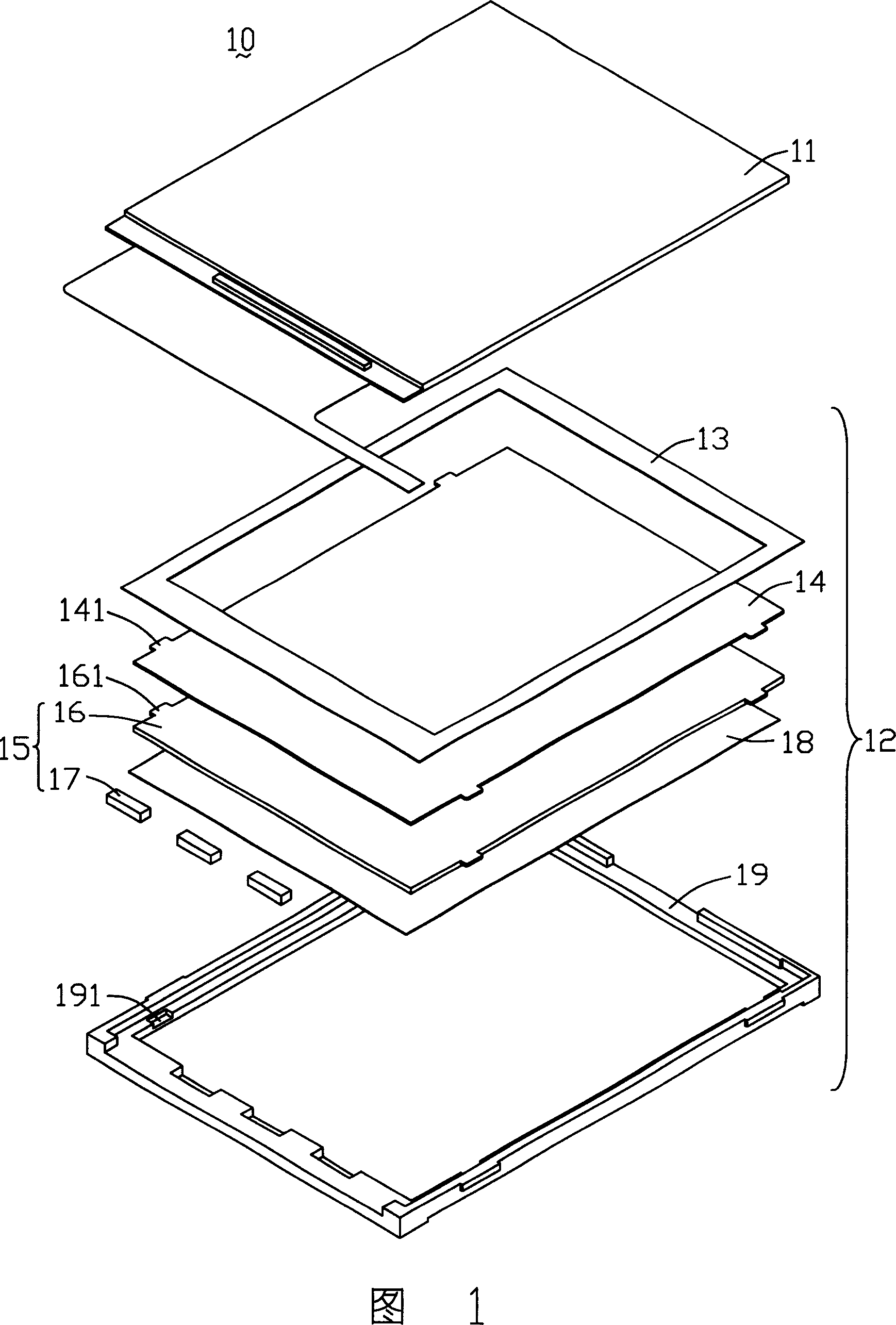

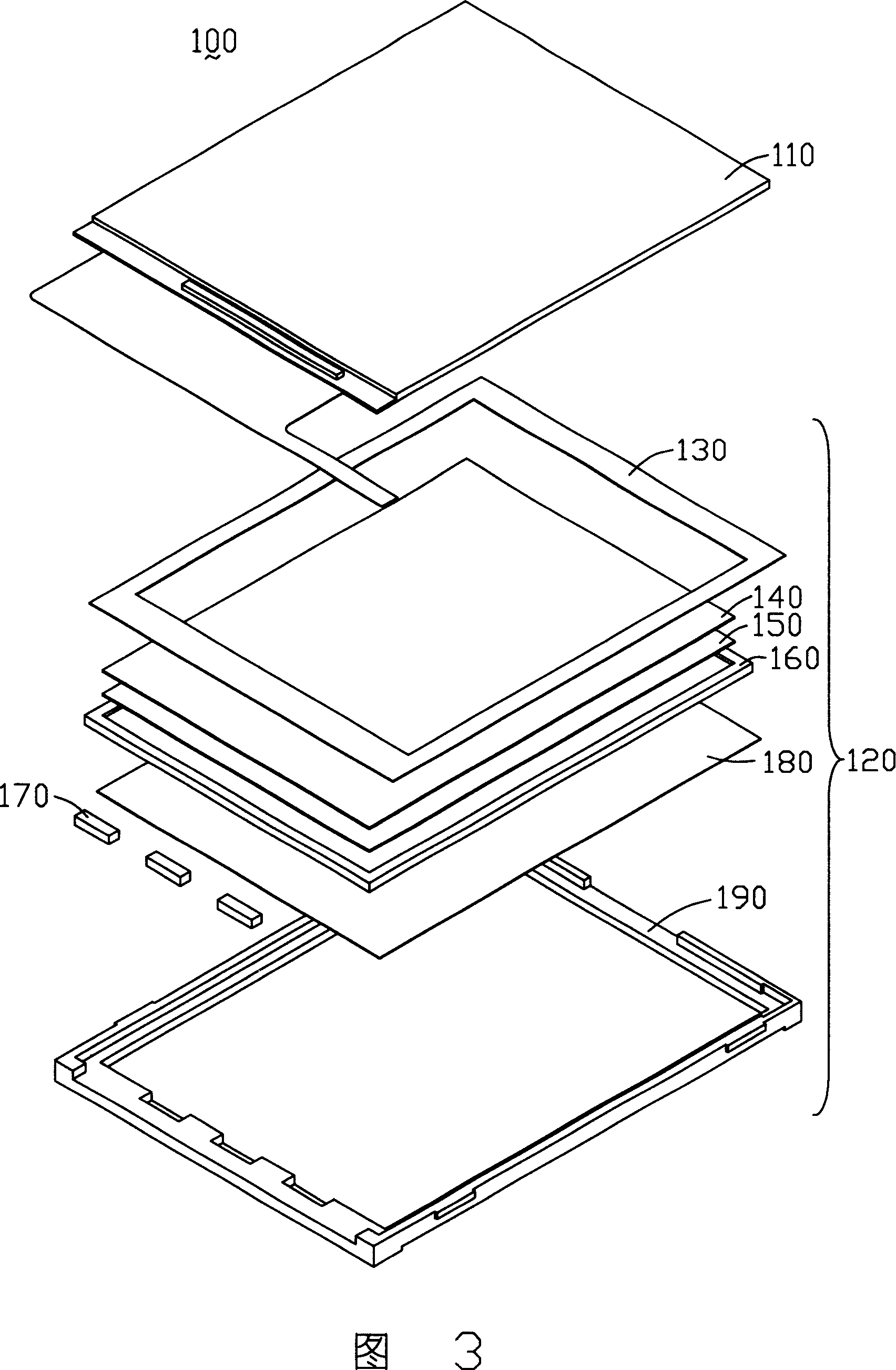

[0023] Please refer to FIG. 3 , which is a schematic structural diagram of a liquid crystal display device 100 using a light guide plate 160 . The liquid cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com