Feeding method for multiple site punching of drawn hardware piece

A multi-station, workpiece technology, applied in the direction of manufacturing tools, positioning devices, metal processing equipment, etc., can solve the problems of slow development of multi-station presses, high production costs, and high technical content, to reduce the technical threshold and production. Cost, overcoming the effect of immobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

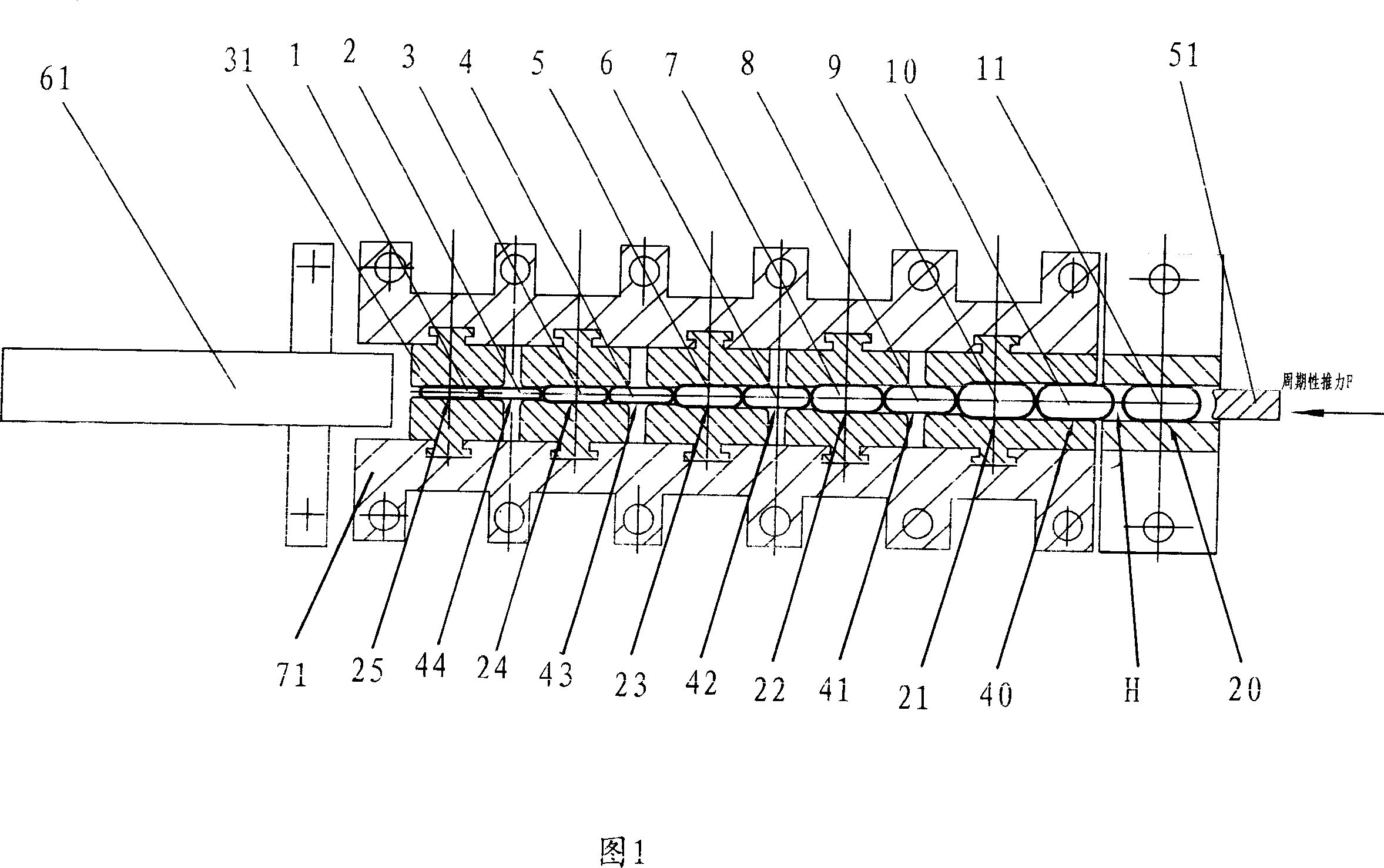

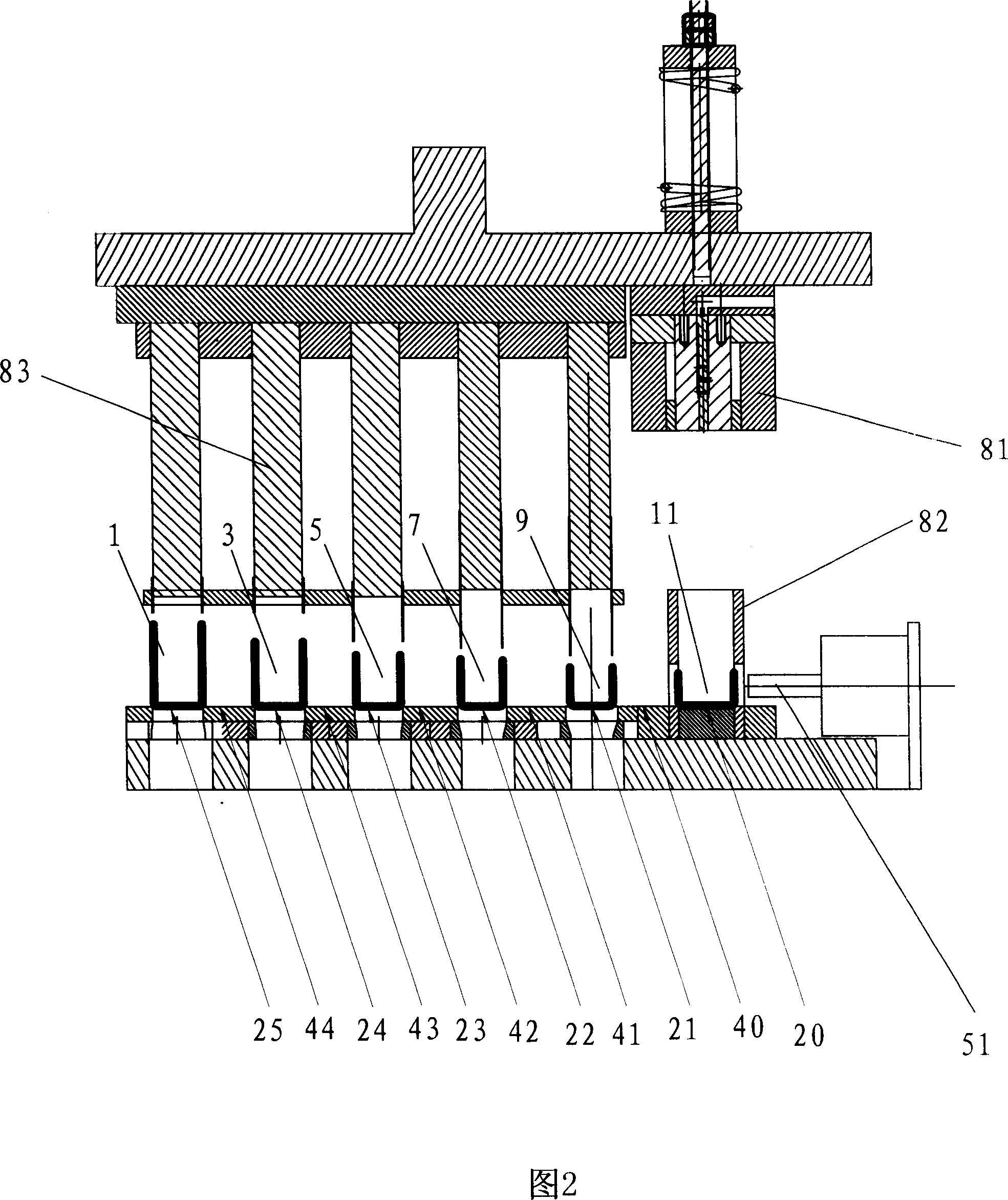

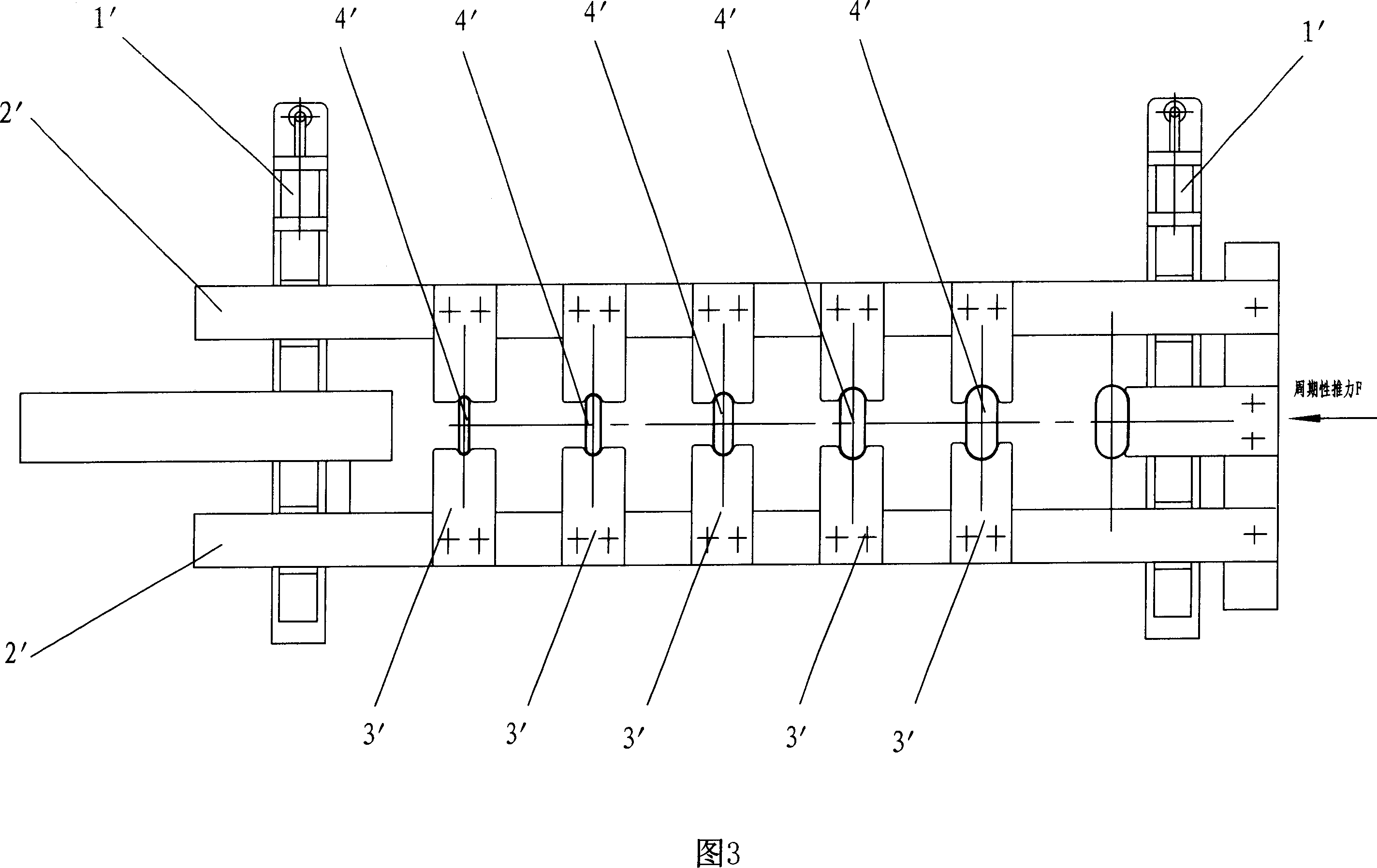

[0040] The feeding process of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0041] Description of figure number:

[0042] 1. The first workpiece; 2. The second workpiece; 3. The third workpiece; 4. The fourth workpiece;

[0043] 5. The fifth workpiece; 6. The sixth workpiece; 7. The seventh workpiece; 8. The eighth workpiece;

[0044] 9. The ninth workpiece; 10. The tenth workpiece; 11. The eleventh workpiece;

[0045] 20. Prefabrication station; 21. First station; 22. Second station; 23. Third station;

[0046] 24. The fourth station; 25. The fifth station;

[0047]31. Conveying track;

[0048] 40. Front transition station; 41. First transition station; 42. Second transition station;

[0049] 43. The third transition station; 44. The fourth transition station;

[0050] 51. Cylinder rod;

[0051] 61. Finished product conveyor belt;

[0052] 71. Fixed plate;

[0053] 81. Upper mold;

[0054] 82. Lower mold;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com