Mechanical vibration state signal acquisition and analysis system

A state signal, analysis system technology, applied in the direction of using electrical devices, instruments, measuring devices, etc., to achieve the effect of strong anti-interference ability, high integration, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

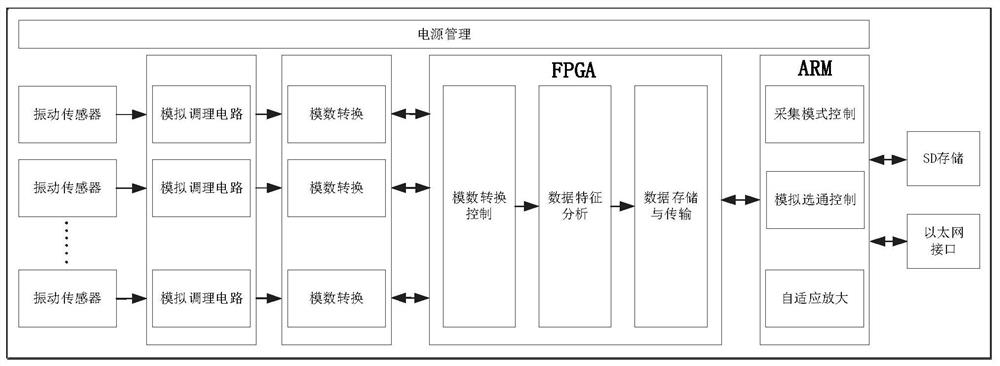

[0076] Such as figure 1 As shown, embodiment 1 of the present invention provides a mechanical vibration state signal acquisition and analysis system, the overall structure is as follows figure 1 As shown, it is divided into five modules:

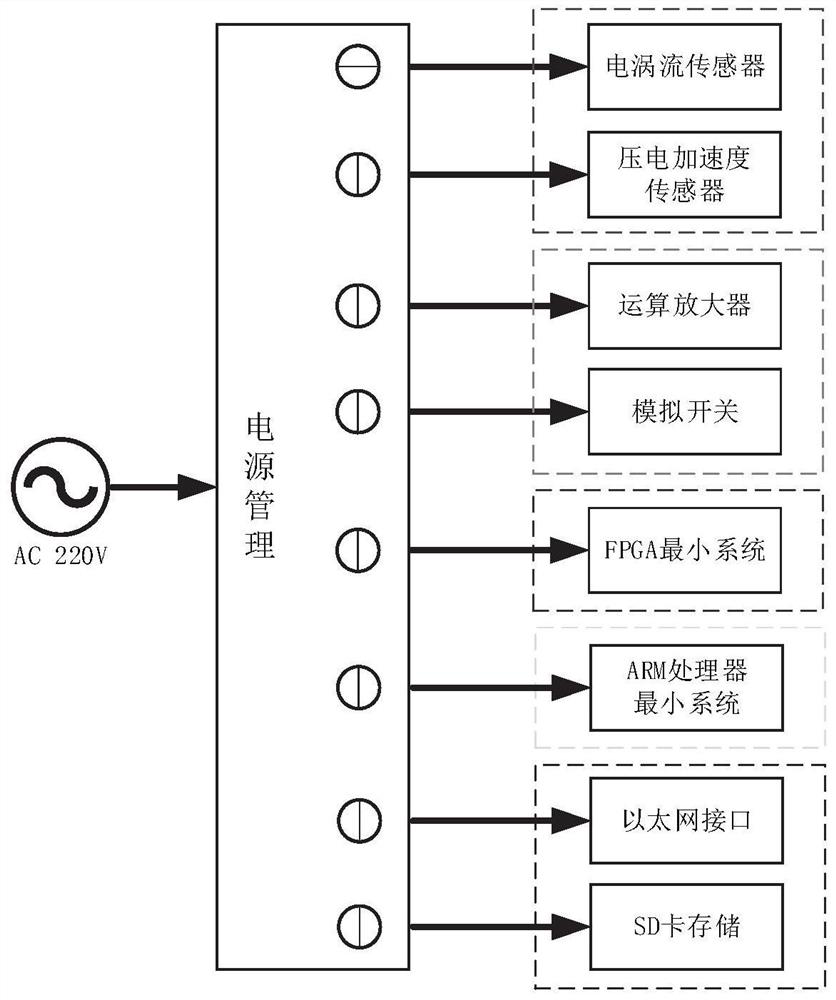

[0077] (1) The power management module is responsible for providing accurate and stable constant voltage and constant current sources for sensors and the entire system;

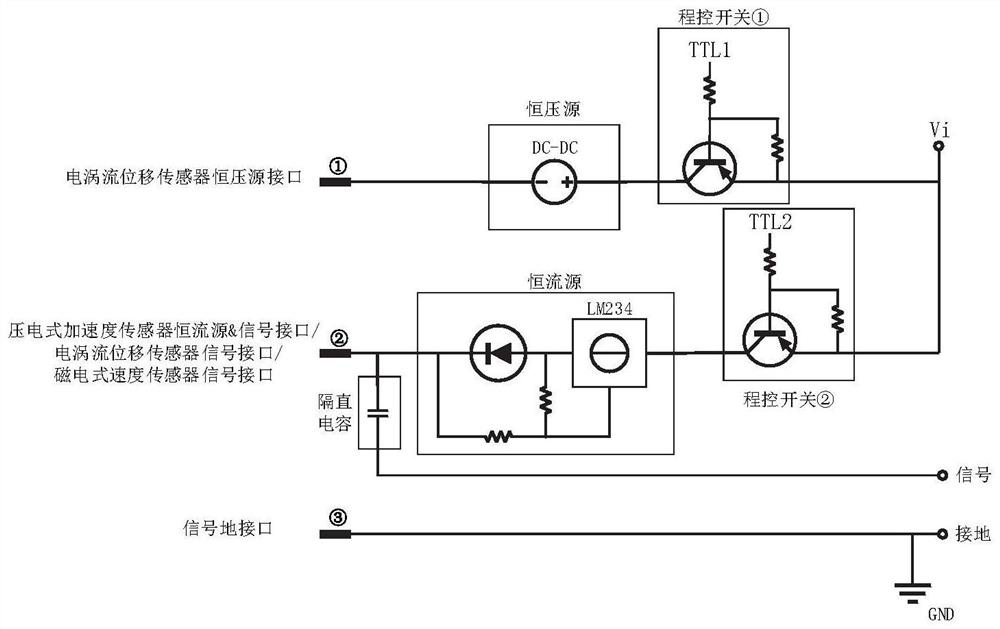

[0078] (2) The analog conditioning circuit module is responsible for completing the data preprocessing processes such as signal differential input of each channel, adaptive amplification, band-pass filtering, differential operation, integral operation, and analog gating;

[0079] (3) Analog-to-digital conversion module, responsible for converting sixteen channels of vibration analog signals into 24bit digital signals and transmitting them to FPGA;

[0080] (4) The FPGA functional module is responsible for providing frequency modulation clocks for each acquisition channel;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com