Bag sandwiching hollow glass

An encapsulated, glass technology, applied in parallel glass structures and other directions, can solve the problem of complex process and high cost, and achieve the effects of prolonging service life, improving temperature and sound insulation performance, and simplifying manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

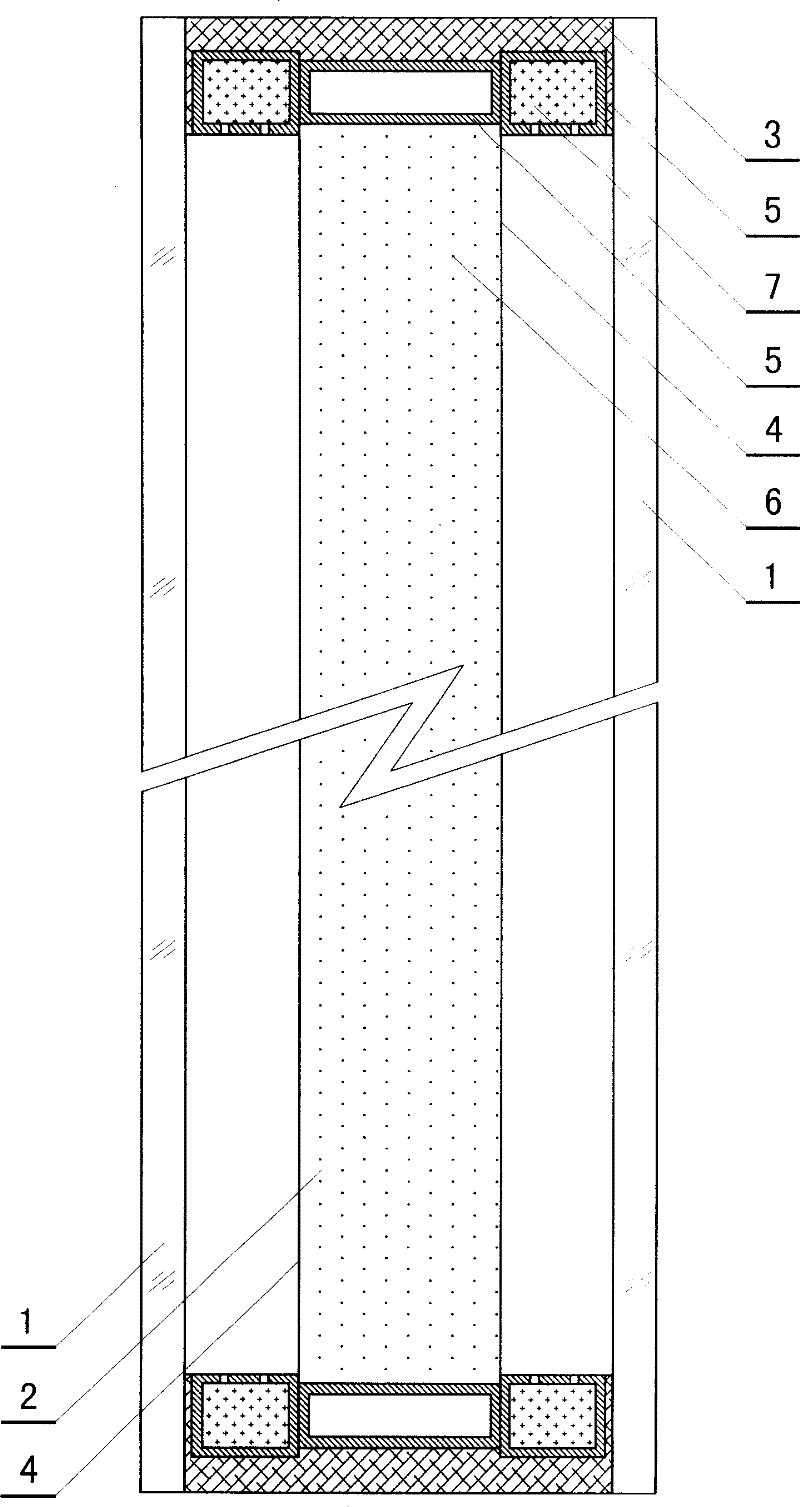

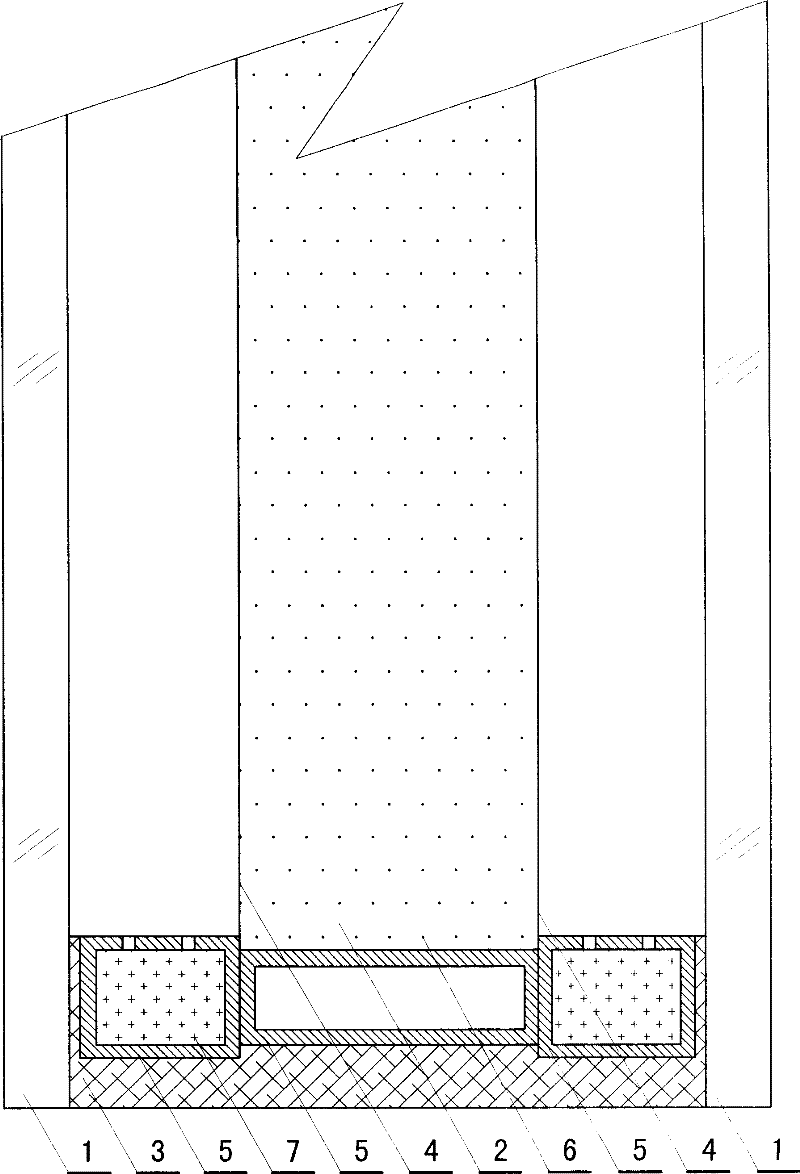

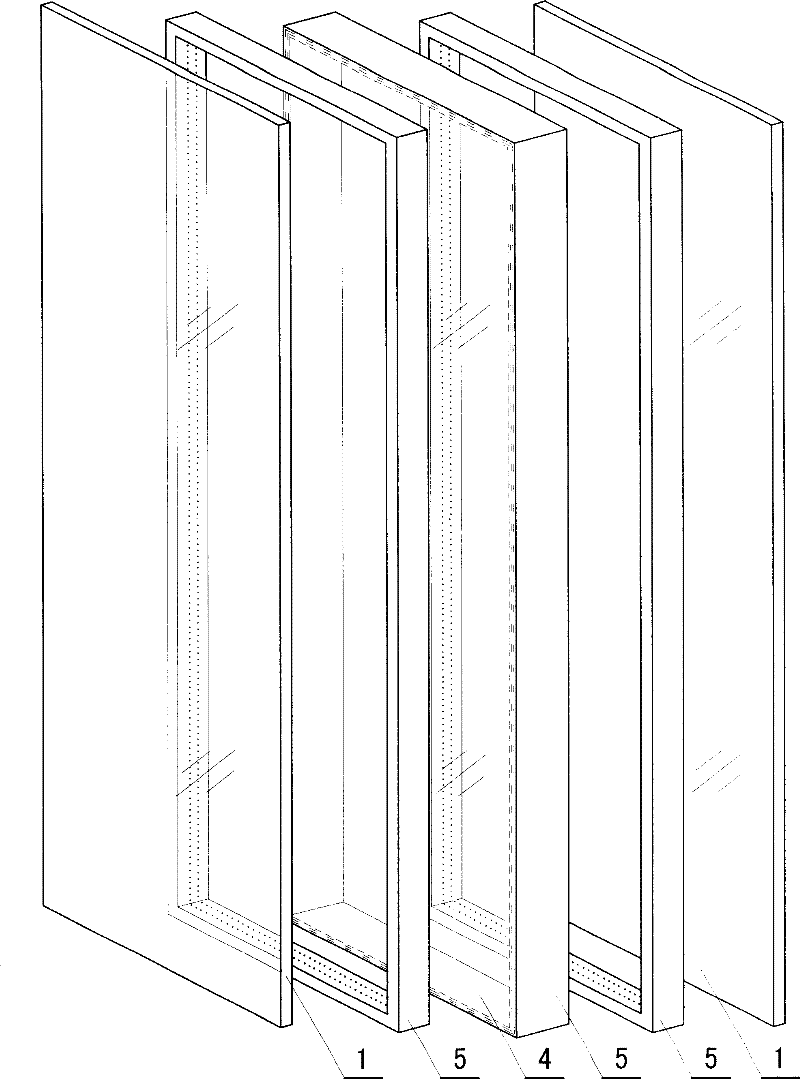

[0011] Compared with multi-layer insulating glass, gas-filled insulating glass, vacuum insulating glass or multi-layer diaphragm insulating glass, the key improvement of the encapsulated insulating glass is the prefabricated and sandwiched flat airbag (2). The flat airbag (2) has a simple structure, as long as it is filled with a temperature-insulating inert gas (6) which is close to the atmospheric pressure and is strictly sealed to keep the diaphragm (4) relatively flat, this makes the encapsulated insulating glass in the sealing process, The temperature and sound insulation performance, product weight and cost have been significantly simplified and improved. During production, the pocket-type insulating glass can be used with transparent, colored, coated, tempered, interlayer and other ordinary or safety glass of various thicknesses like the current production of insulating glass; the diaphragm (4) forming the flat airbag can be transparent , colored, discolored or patterne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com