Inclined flow tube shell type heat exchanger

A heat exchanger and flow tube technology, which is applied in the field of heat exchange equipment, can solve the problems that the heat exchange area cannot be fully utilized, it is difficult to reasonably adjust the temperature of the process medium, the large flow of the shell side and the heat transfer dead zone, etc., to eliminate the flow Dead zone, obvious disturbance effect, and improved shell-side heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

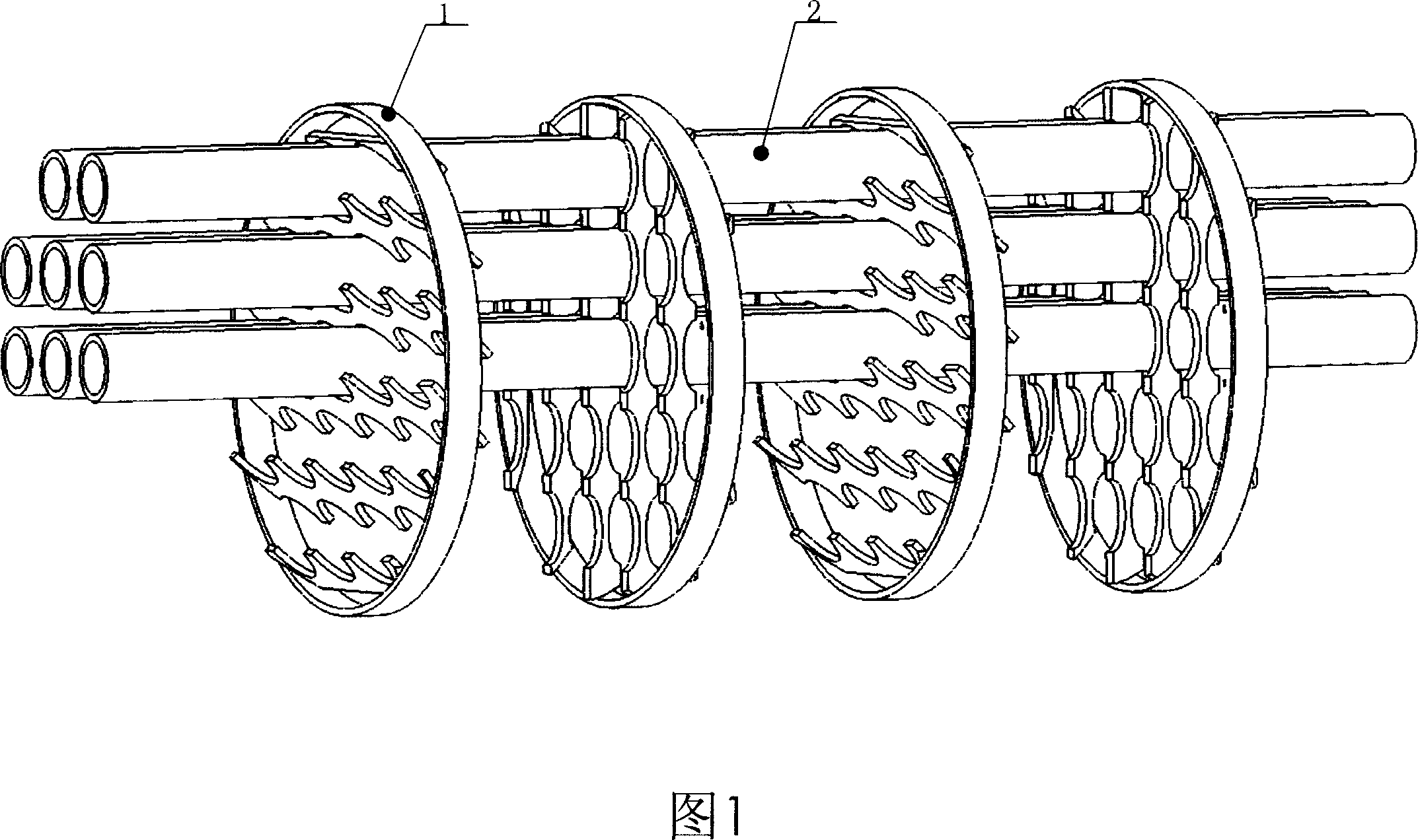

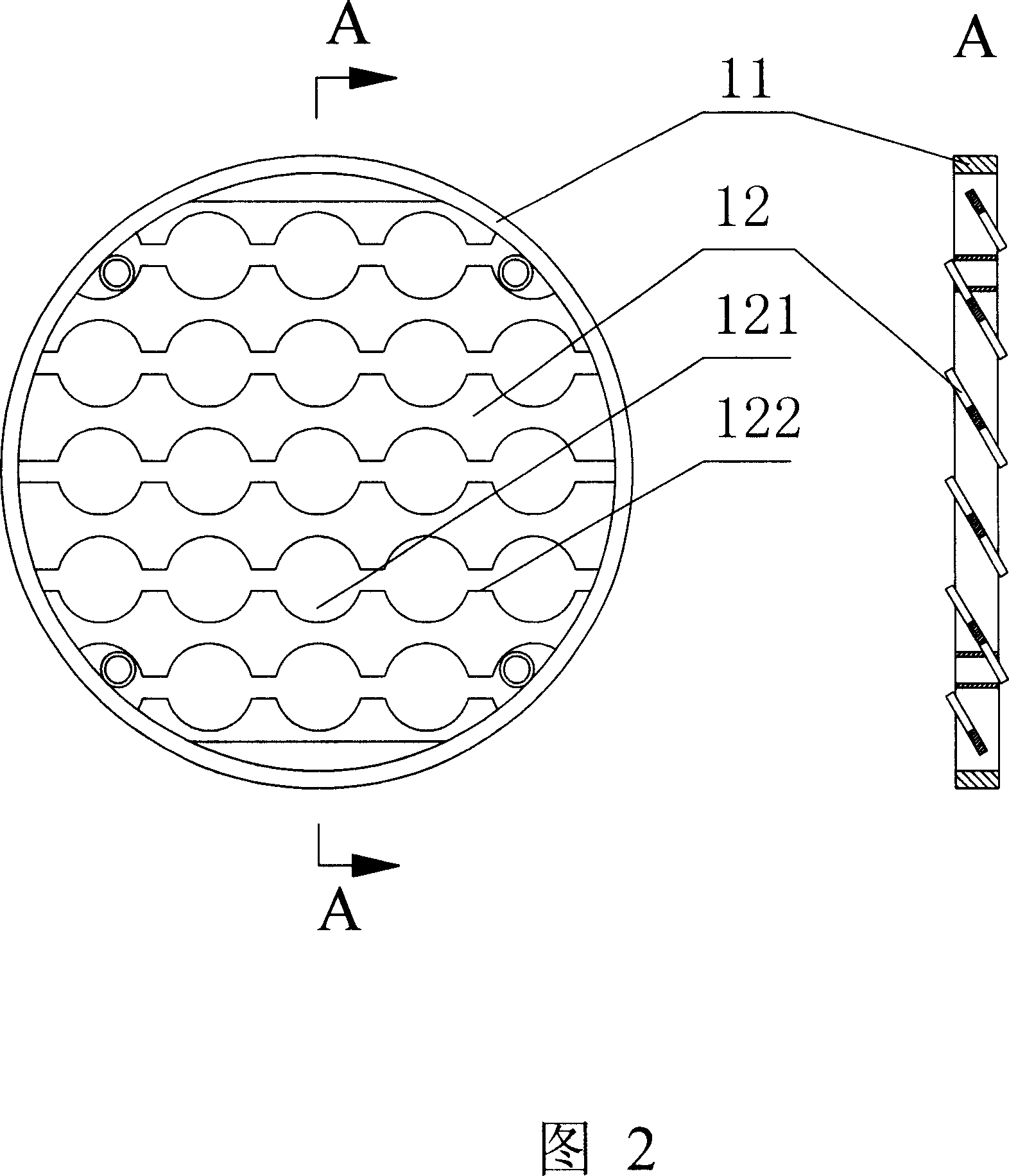

[0026] Embodiment 1: As shown in Figure 1, Figure 2, Figure 5(a), and Figure 6, the oblique flow shell-and-tube heat exchanger mainly includes a baffle grid 1 and a heat exchange tube 2, and the baffle grid 1 is composed of a deflector Flow ring 11 and curtain baffles 12 welded on the baffle grille are formed. The curtain baffles 12 have semicircular openings 121, and there are protrusions 122 between two openings 121. The size of openings 121 is larger than The outer diameter of the heat exchange tube is 0.3 mm, the inclination angle between the curtain baffle 12 and the baffle ring 11 is 45°, and the curtain baffles 12 on any two adjacent baffle grids 1 are arranged orthogonally.

Embodiment 2

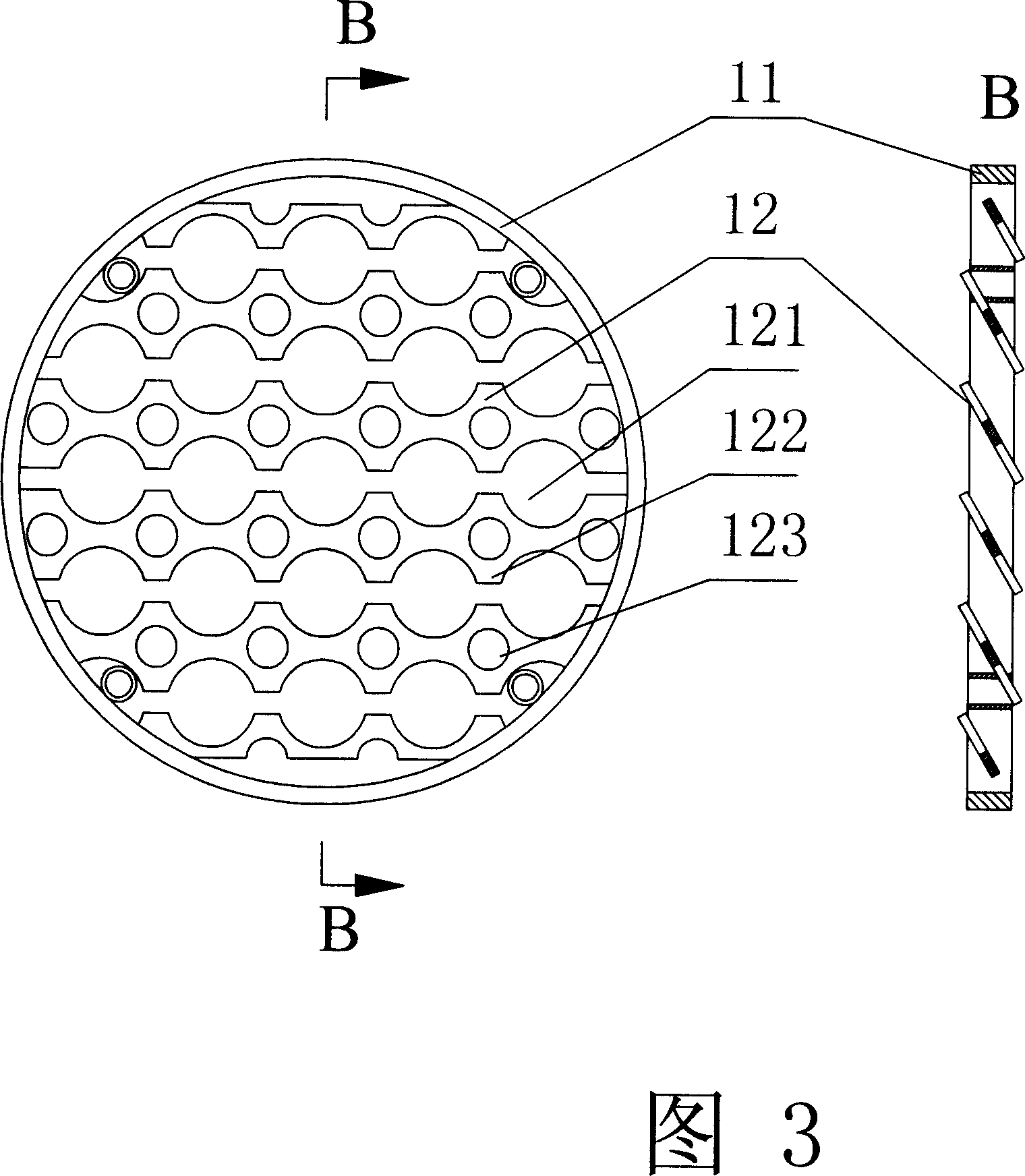

[0027] Embodiment 2: As shown in Fig. 3 and Fig. 5(b), the difference between this inclined flow shell-and-tube heat exchanger and Embodiment 1 is that: the curtain baffle 12 has a semicircular opening 121, and the semicircular An opening (123) is provided in the middle of the opposite protrusion 122 between the circular openings 121, the size of the opening 121 is 0.4mm larger than the outer diameter of the heat exchange tube 2, and the gap between the curtain baffle 12 and the baffle ring 11 The inclination angle is 30°, and the curtain baffles 12 on two adjacent baffles 1 are arranged symmetrically.

Embodiment 3

[0028] Embodiment 3: As shown in Fig. 4(a) and Fig. 5(c), the difference between the inclined flow shell-and-tube heat exchanger and Embodiment 1 is that the curtain baffle 12 has a square opening 121, The size of the square opening 121 is 0.45 mm larger than the outer diameter of the heat exchange tube 2, the inclination angle between the curtain baffle 12 and the baffle ring 11 is 60 °, and the curtain baffles on the two adjacent baffles 1 The flow sheets 12 are arranged in parallel.

[0029] Through the above technical scheme, the curtain baffles 12 on the adjacent baffles 1 can realize the complete support and positioning of the heat exchange tubes 2 in the horizontal and vertical positions, and at the same time, the curtain baffles 12 have a certain effect on the shell-side fluid. Strong guiding and disturbing effect, inclined flow passages are formed between two adjacent curtain baffles 12, the shell-side fluid flows into these inclined passages, and the flow direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com