Infrared heater

An infrared heater and outer tube technology, applied in the shape of the heating element, etc., can solve the problems of inconvenient daily use, troublesome cleaning of the reflector, and affecting the heating effect, and achieve the effects of easy adjustment, convenient disassembly and assembly, and protection of the lead wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

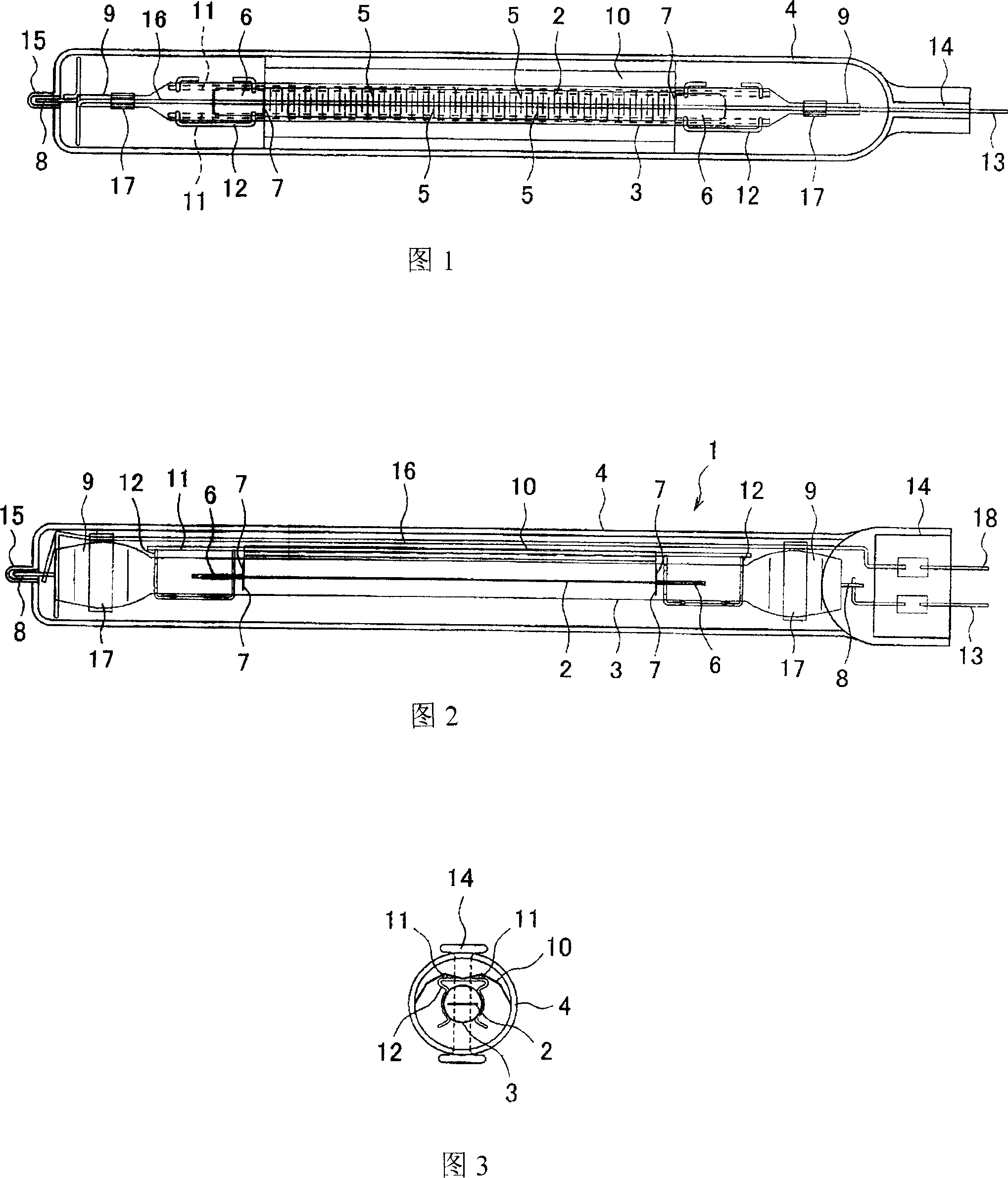

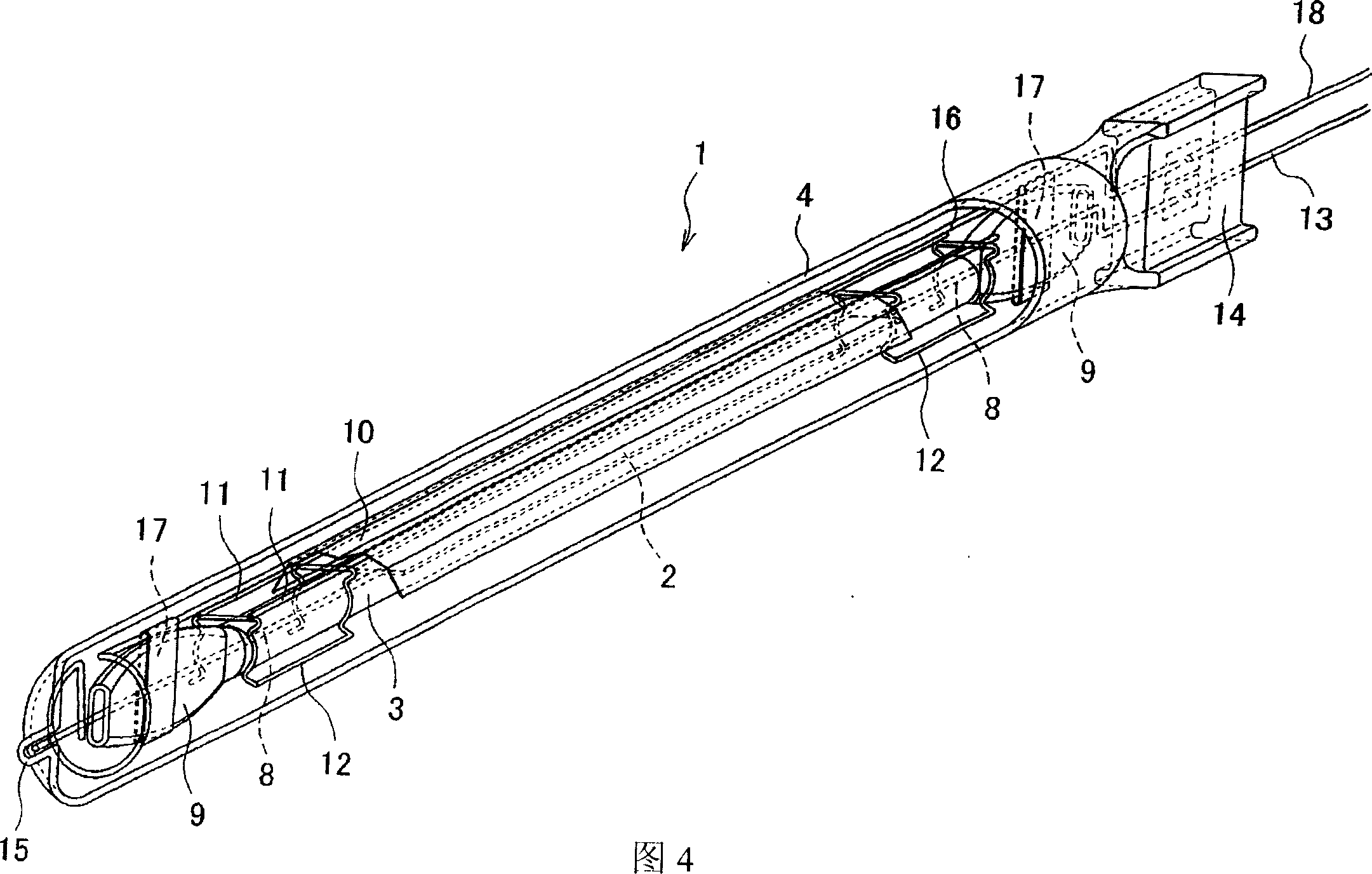

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0024] An infrared heater 1, comprising a glass tube and an electrified carbonaceous heating element 2, the glass tube is a double tube, which includes an inner tube 3 sealed into the carbonaceous heating element 2 and an inner tube sealed into the inner tube The outer tube 4 of the tube 3, the inner tube 3 and the outer tube 4 are all made of transparent glass, and their cross sections are all circular.

[0025] The carbonaceous heating element 2 is in the shape of an elongated thin plate. On the middle part except the two ends, there are a plurality of strips which are cut into each other alternately from the edge of one end in the length direction to the width direction and cut in at equal intervals. The slits 5 form a tortuous electrical path, and the interval between two adjacent slits 5 is determined by the specific required resistance.

[0026] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com