Annular concentric stranded bead cord and method for producing the same

A ring-shaped, bead-shaped technology, applied to tires, bead edges, tire parts, etc., can solve problems such as uselessness and insufficient rigidity, and achieve high performance and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

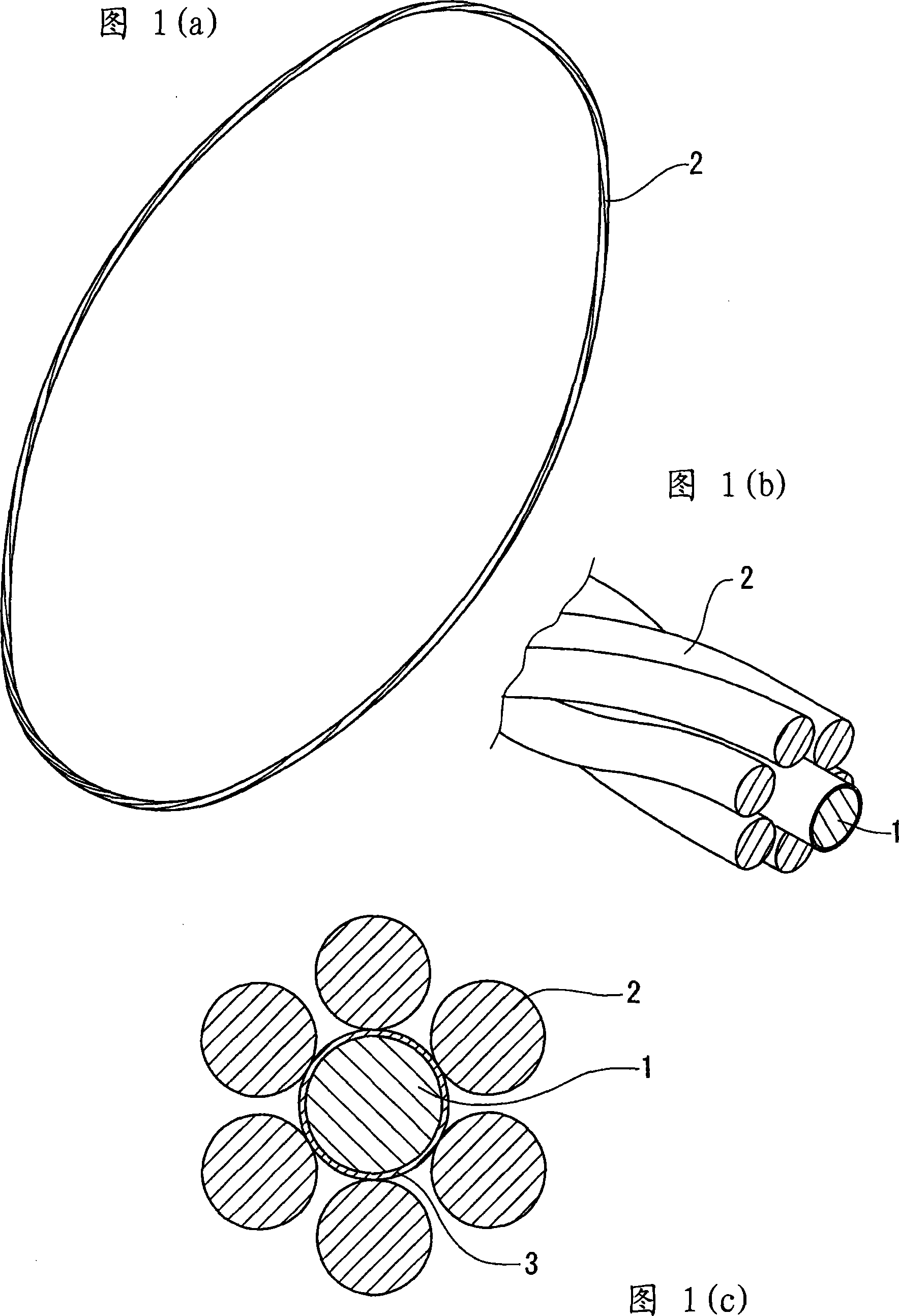

[0041] Embodiments of the present invention will now be described with reference to the drawings. As shown in FIGS. 1( a ) to 1 ( c ), the endless concentrically placed bead cord of this embodiment includes an annular core 1 and a wrapping wire 2 helically wound around the annular core 1 six times. In this embodiment, the wrapping wire 2 forms a single sheath. However, the wrapping wire 2 can form multiple sheaths.

[0042] The annular core 1 is formed by circularly bending steel wires, welding their ends together, and applying a corrosion-resistant coating to the wire surface to form a corrosion-resistant coating film 3 on the wire surface over its entire circumferential length. By selecting an appropriate coating method and adjusting its thickness, the coating film 3 is formed so that its surface is smooth. This enables smooth winding of the wrapping wire 2 around the annular core 1 .

[0043] The winding wire 2 is made of high carbon steel and has a smaller diameter than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com