Method and device for lye extraction desulfurization

A lye extraction and lye technology, applied in the direction of refining with alkaline aqueous solution, etc., can solve the problems of difficult release, inability to achieve, and the desulfurization effect is not obvious, and achieve the effect of promoting separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The hydrocarbon stream to be desulfurized is FCC gasoline fraction, and its basic properties are shown in Table 1. Among them, the determination of sulfur content adopts microcoulomb method, and the determination of thiol adopts potentiometric titration method.

[0042]

Distillation range (℃)

Sulfur content (ppm)

Mercaptan sulfur content

(ppm)

FCCG1

33~98

139

71

FCCG2

34~114

73

20

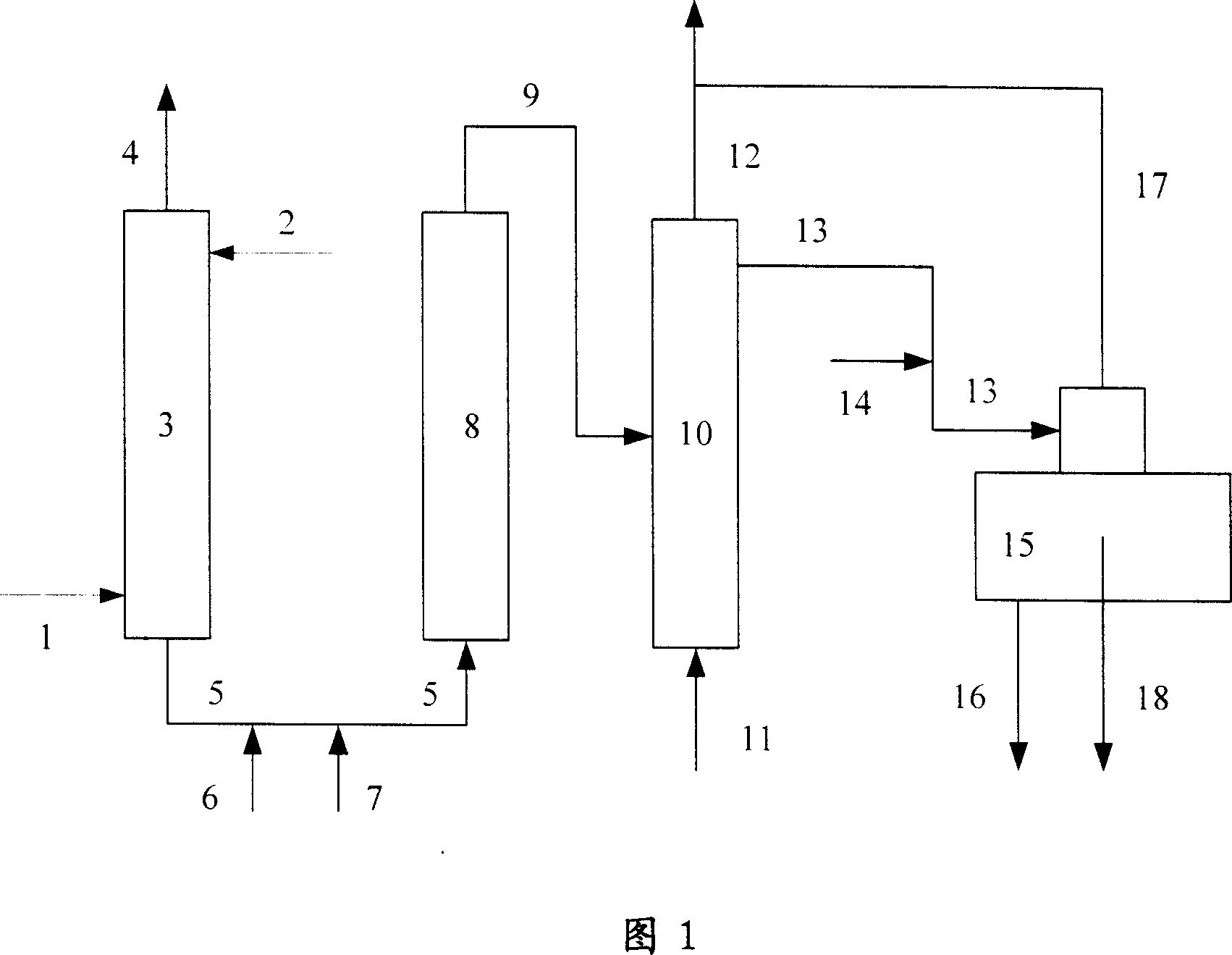

[0043] The hydrocarbon streams FCCG1 and FCCG2 in Table 1 were desulfurized using the flow chart shown in FIG. 1 . A NaOH solution with a concentration of 15% (weight) is used, and the content of sulfonated cobalt phthalocyanine in the alkali solution is 100 ppm. In the extraction system, the volume ratio of alkali liquor to hydrocarbon stream is 1:9, the temperature is normal temperature, and the pressure is 0.50MPa. In the oxidation system, the injection volume of ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com