Film plating method of solar stove panel

A technology of concentrating plate and solar cooker, which is applied in solar thermal devices, solar thermal power generation, sputtering coating, etc., can solve the problem that the preparation process of reflective film is not proposed, the thickness is difficult to keep uniform, and the concentrating plate is not enough. Pressure and other problems, to achieve the effect of simple structure, low cost and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

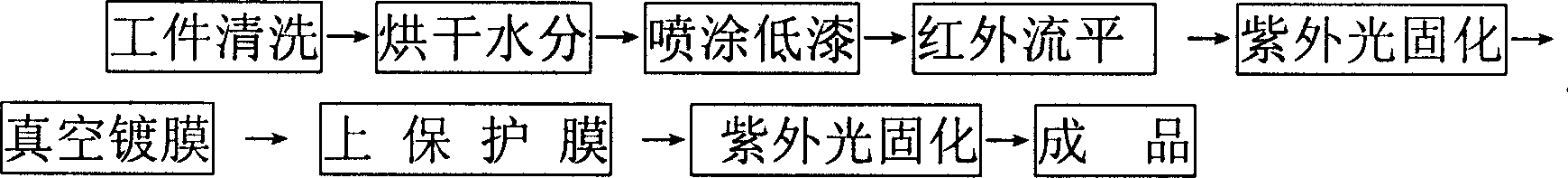

Method used

Image

Examples

Embodiment Construction

[0008] specific implementation plan

[0009] 1. Cleaning of solar cooker concentrator

[0010] In order to improve the adhesion, uniformity and metal effect of the coating layer, it is necessary to thoroughly clean the solar cooker concentrating plate formed by ABS engineering plastics as the base material, and remove the oil and weak spots such as the release agent left during processing. Adsorption layer. It can be cleaned with ordinary detergent or surfactant, etc., then rinse with clean warm water, and at the same time dry it or air dry it.

[0011] 2. Spraying primer for concentrating panels of solar cookers

[0012] Spraying the primer is to enhance the adhesion between the aluminum film and the substrate of the solar cooker concentrator, to modify and cover all the defects on the surface of the workpiece, so that it becomes a smooth and full-bodied coating surface for easy coating. The primer is the key link to protect the reflective properties of the solar cooker co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com