Dynamometer machine monitoring system having control and data acquisition function

A technology of data acquisition and monitoring system, which is applied in the direction of motor generator testing, etc., can solve the problems of slow test speed, inconvenient use, lack of data acquisition and monitoring functions, etc., to improve dynamometer efficiency, improve work efficiency, and facilitate The effect of dynamometer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

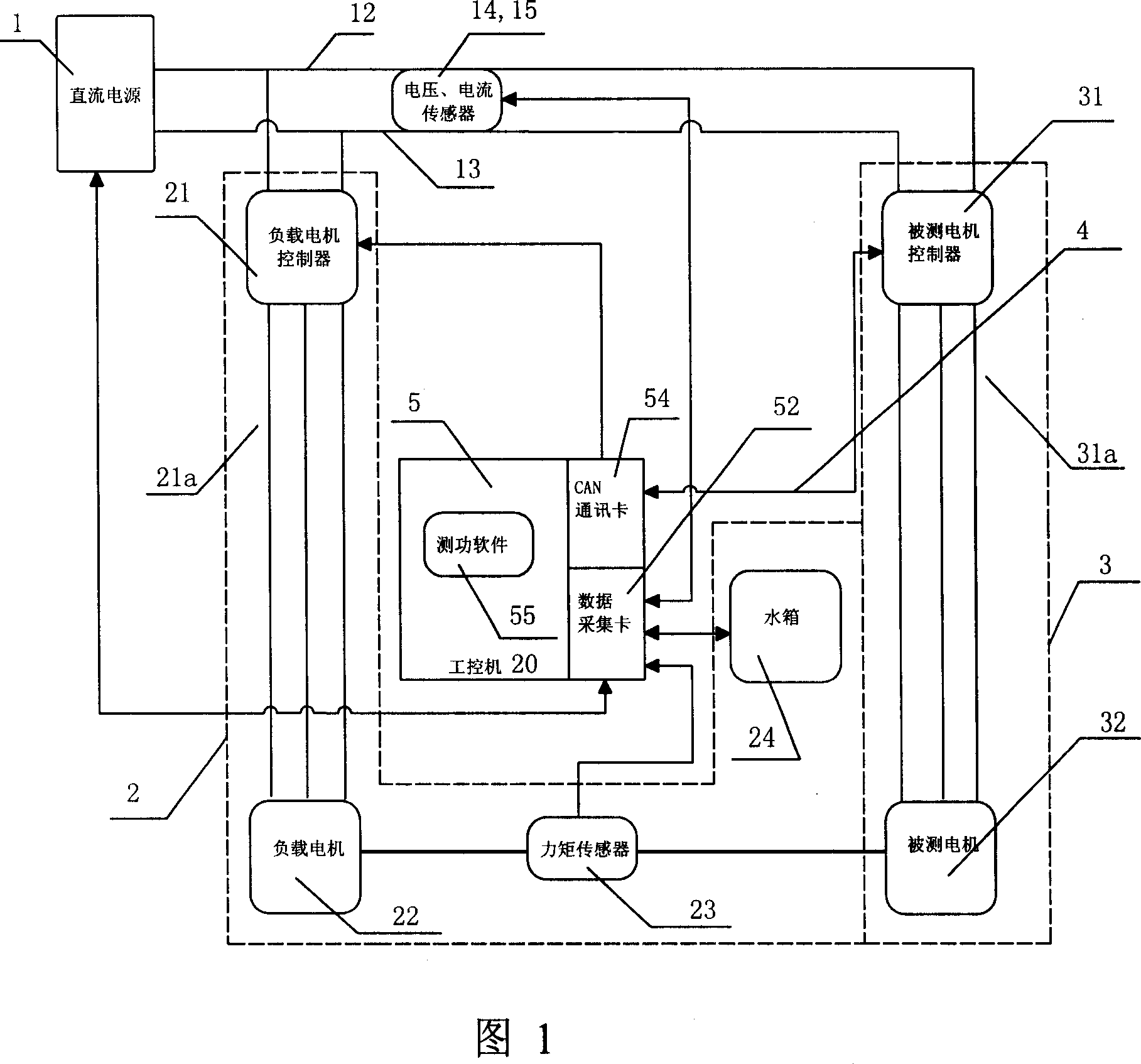

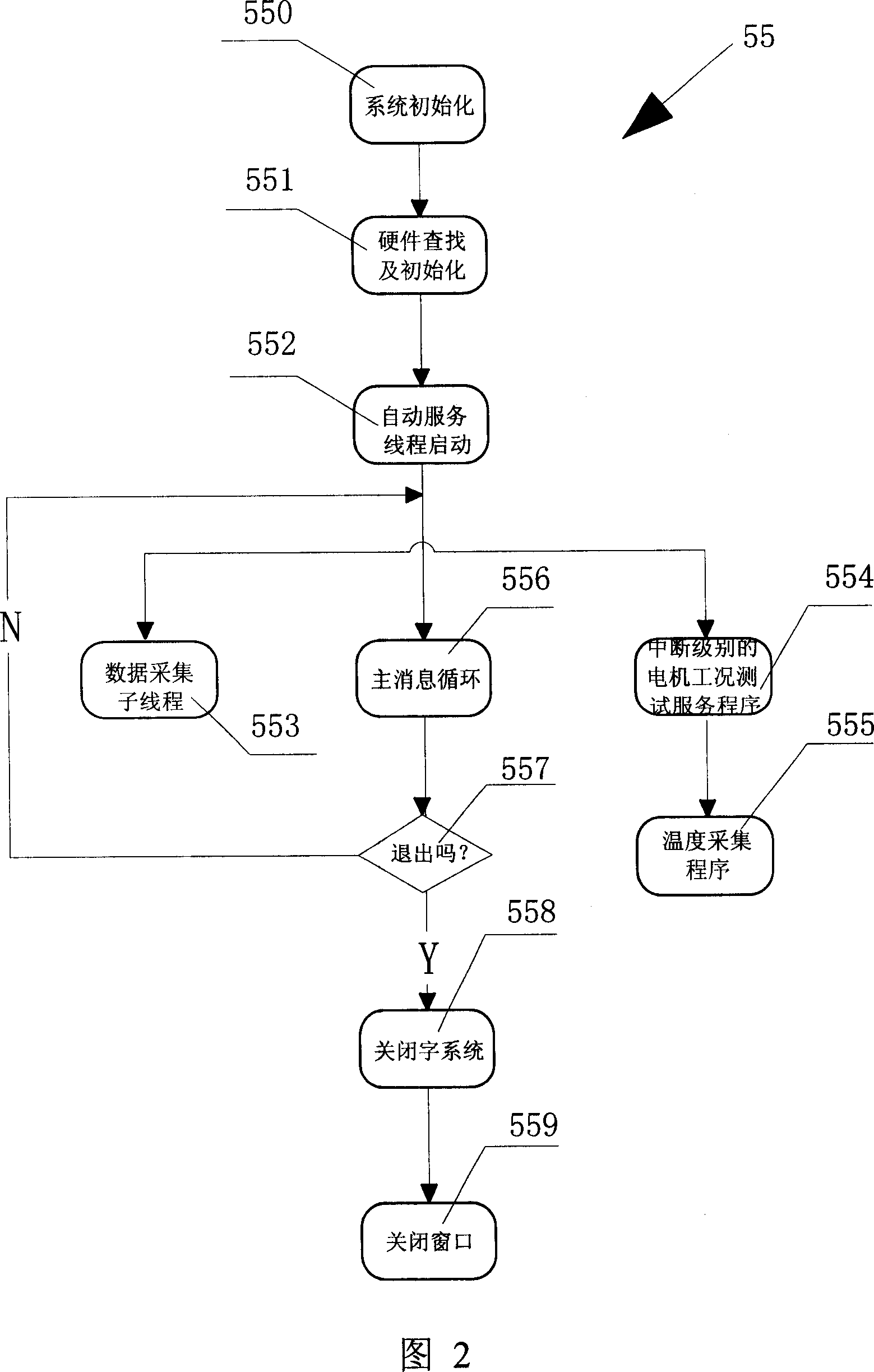

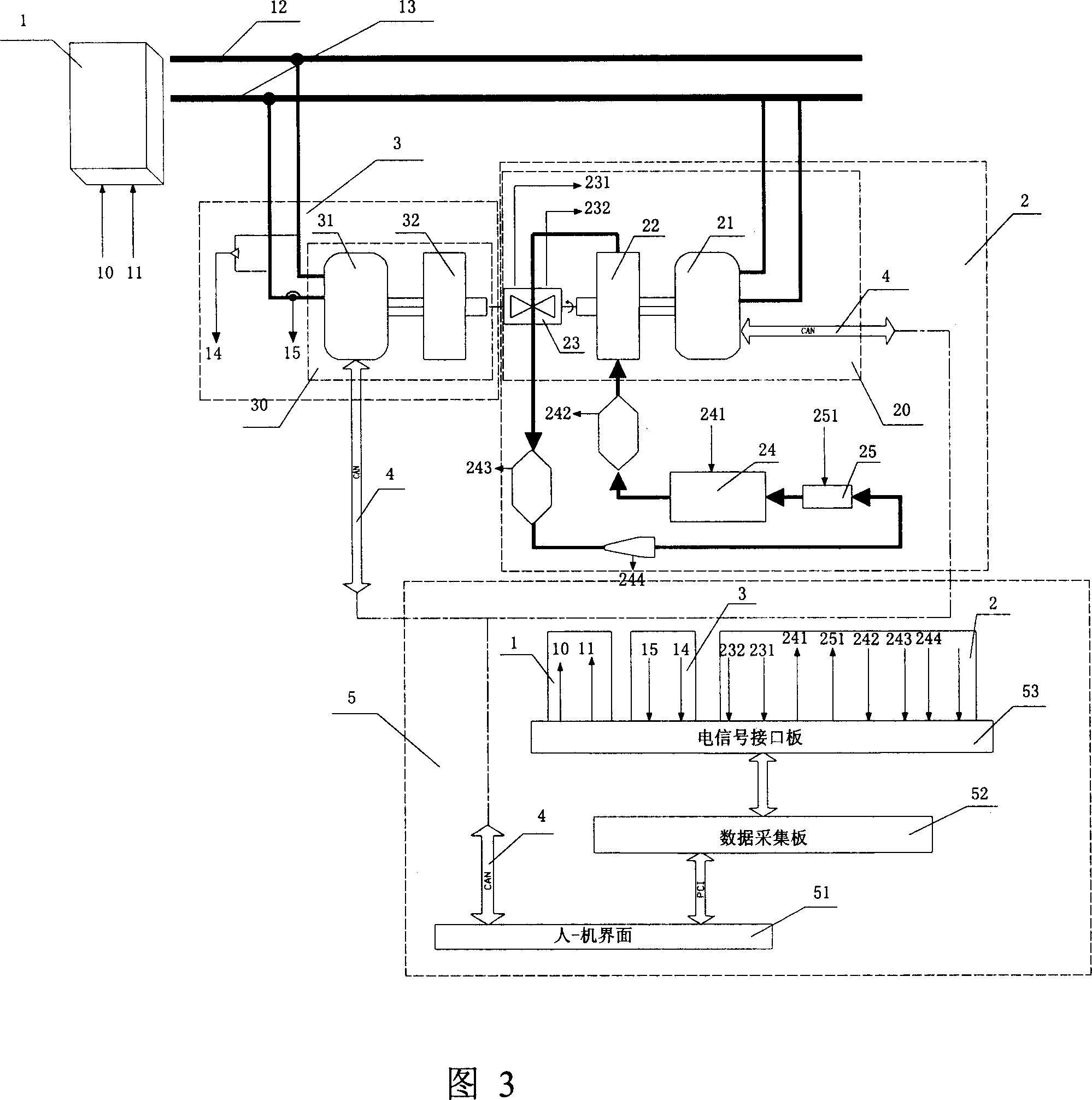

[0072] Two preferred embodiments of the present invention are given below based on FIGS. 1 to 4, and described in detail, so as to better illustrate the structural and functional characteristics of the present invention, rather than limiting the scope of the present invention.

[0073] Refer to Figure 1, which shows the system structure of the present invention. As shown in the figure, the dynamometer of the present invention includes a DC power supply 1, which is connected in parallel to the load motor controller 21 and the motor under test via two power supply buses 12, 13 The controller 31 respectively connects the load motor 22 and the motor under test 32 with three-phase AC power supply lines 21a and 31a, and a torque sensor 23 is connected to the rotating shafts of the two motors 22, 32. The two motors 22 and 32 both have the function of four-quadrant operation. When the tested motor 32 is in forward (or reverse) electric operation, the energy flow is: power supply bus 12 (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com