Aqueous adhesive for shoes and its production method

A technology for adhesives and shoes, applied in the directions of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of high production cost, shortage, limited production and use scope, etc., to reduce raw material costs and achieve excellent elasticity. , the effect of improving the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0041] Example one:

[0042] First, the preparation of polyacrylate emulsion.

[0043] Polyacrylate emulsion components and weight percentage:

[0044] Deionized water 34.2% acrylic acid 0.5%

[0045] Butyl acrylate 38% Methyl methacrylate 23%

[0046] Isooctyl acrylate 1% Hydroxyethyl acrylate 0.5%

[0047] Emulsifier 2% Buffer 0.2%

[0048] Reducing agent 0.1% Initiator 0.5%

[0049] Prepare the polyacrylate emulsion as follows:

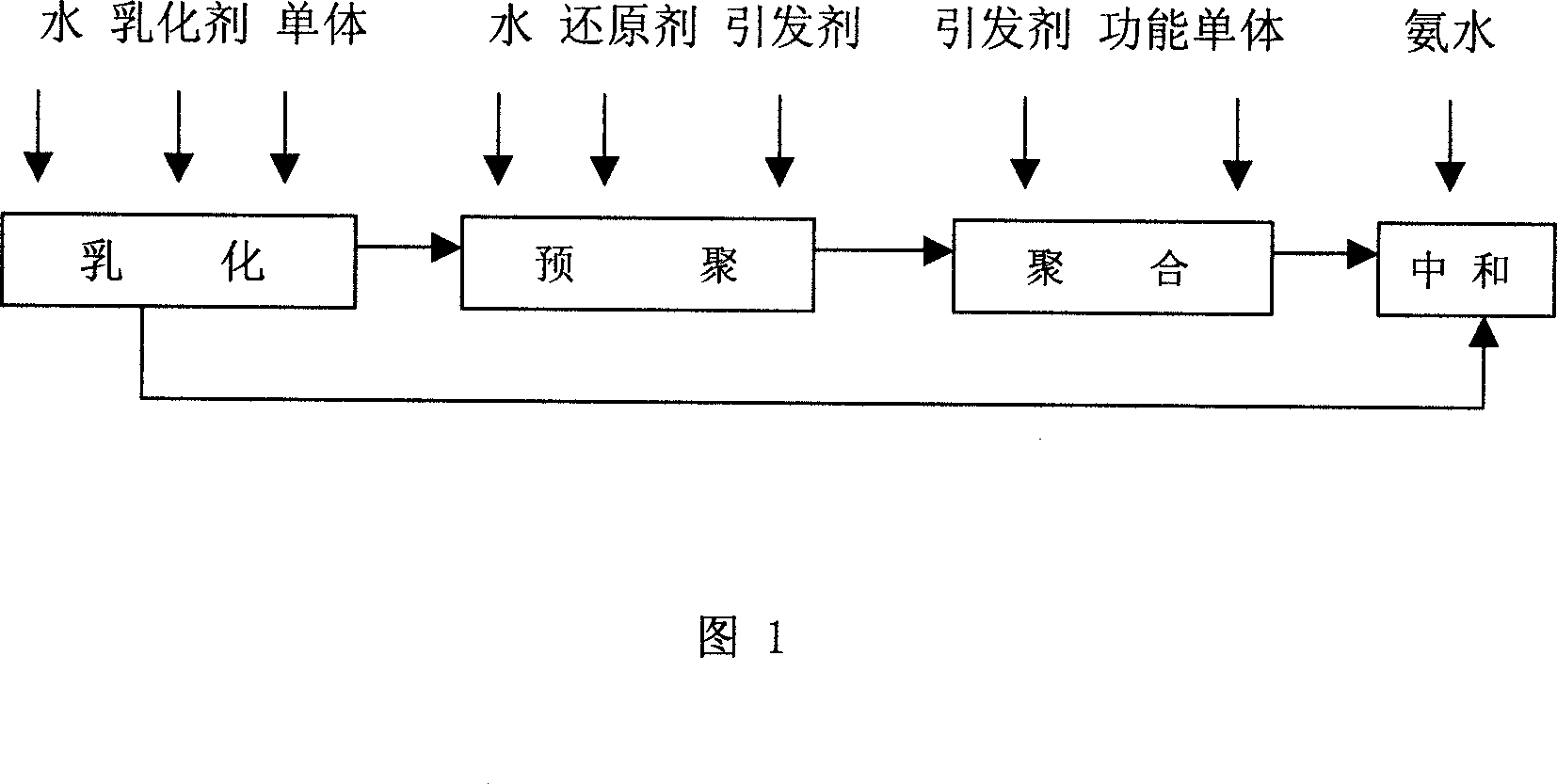

[0050] 1) Emulsification: dissolve the emulsifier in deionized water, add butyl acrylate, acrylic acid, isooctyl acrylate and methyl methacrylate under stirring, and stir and emulsify to obtain a monomer emulsion.

[0051] 2) Prepolymerization: Dissolve the buffer in non-ionized water in the reactor, add a small amount (5%) of monomer emulsion, heat up to polymerization temperature (85°C), add a solution of reducing agent and initiator (50%) , Prepare seed emulsion.

[0052] Three) Polymerization: Drop the remaining monomer emulsion and the remaining (...

Example Embodiment

[0060] Embodiment two:

[0061] First, the preparation of polyacrylate emulsion.

[0062] Polyacrylate emulsion components and weight percentage:

[0063] Deionized water 34.2% acrylic acid 0.5%

[0064] Butyl acrylate 38%, methyl methacrylate 23%,

[0065] Isooctyl acrylate 1%, hydroxyethyl acrylate 0.5%,

[0066]Emulsifier 2%, buffer 0.2%,

[0067] The reducing agent is 0.1%, and the initiator is 0.5%.

[0068] The preparation method of polyacrylate emulsion is the same as in Example 1.

[0069] Second, prepare water-based adhesive for shoes:

[0070] Formula components and weight percentage:

[0071] Polyacrylate emulsion 20%, take 20KG,

[0072] Taiwan's U-88 water-based polyurethane emulsion 76% (commodity), take 76KG,

[0073] Acetone 3%, take 3KG,

[0074] Thickener 1%, take 1KG.

[0075] The preparation method is the same as in Example 1.

Example Embodiment

[0076] Embodiment three:

[0077] First, the preparation of polyacrylate emulsion.

[0078] Polyacrylate emulsion components and weight percentage:

[0079] Deionized water 34.2% acrylic acid 0.5%

[0080] Butyl acrylate 38%, methyl methacrylate 23%,

[0081] Isooctyl acrylate 1%, hydroxyethyl acrylate 0.5%,

[0082] Emulsifier 2%, buffer 0.2%,

[0083] The reducing agent is 0.1%, and the initiator is 0.5%.

[0084] The preparation of polyacrylate emulsion is the same as in Example 1.

[0085] Second, prepare water-based adhesive for shoes:

[0086] Formula components and weight percentage:

[0087] Polyacrylate emulsion 16%, take 16KG,

[0088] Taiwan U-66 water-based polyurethane dispersion 80% (commodity), take 80.7KG,

[0089] Acetone 3%, take 3KG,

[0090] Thickener 0.3%, take 0.3KG.

[0091] The preparation method is the same as in Example 1.

[0092] The above-mentioned water-based adhesive for shoes has been formulated and used, and its technical indicators are as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com