Steel pipe concrete frame-steel truss-concrete combined shear wall and its manufacture method

A technology of steel tube concrete and combined shear walls, which is applied in the direction of walls, building components, and earthquake resistance, to achieve the effects of reducing the axial compression ratio, large economic benefits, and enhanced constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

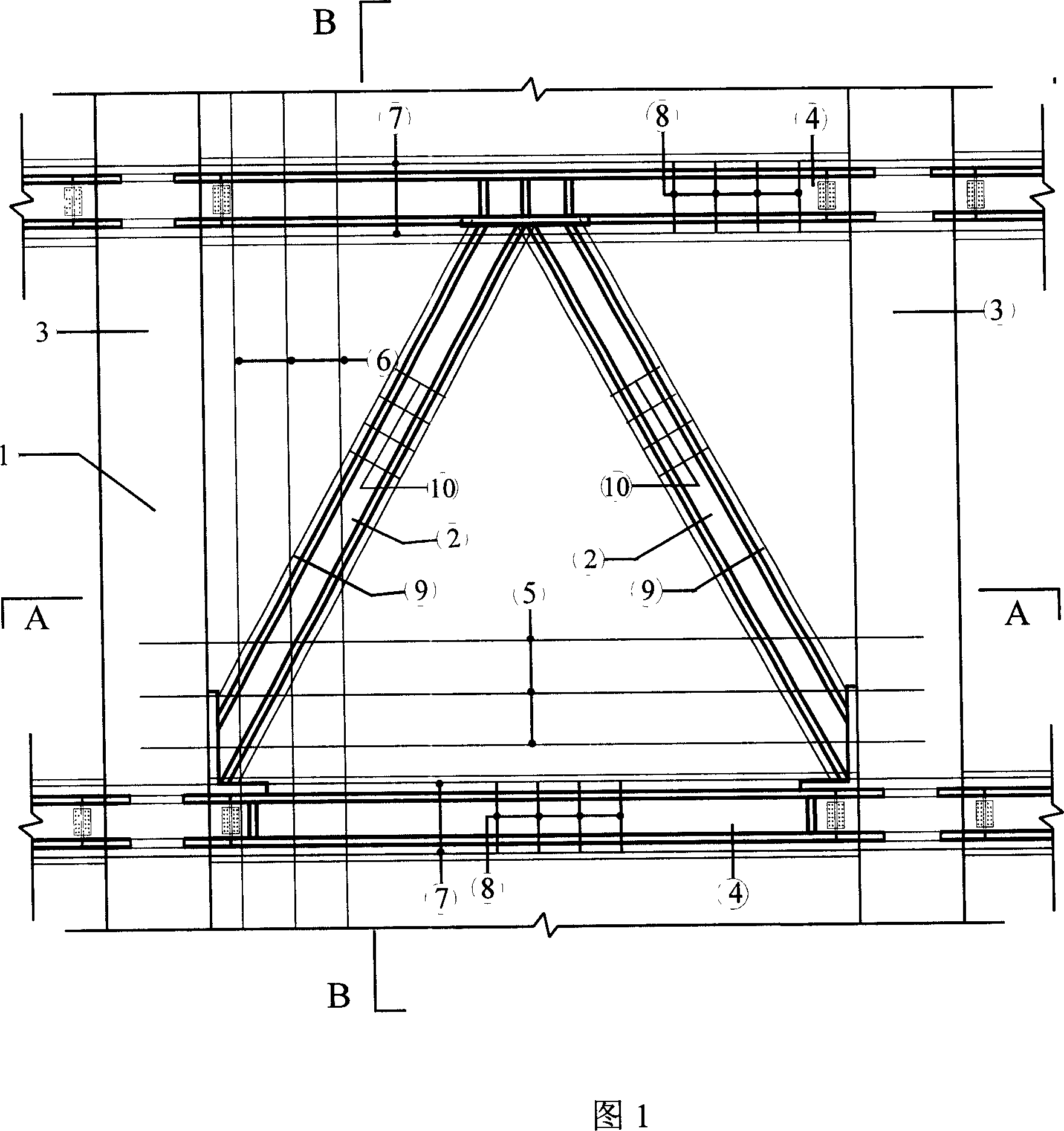

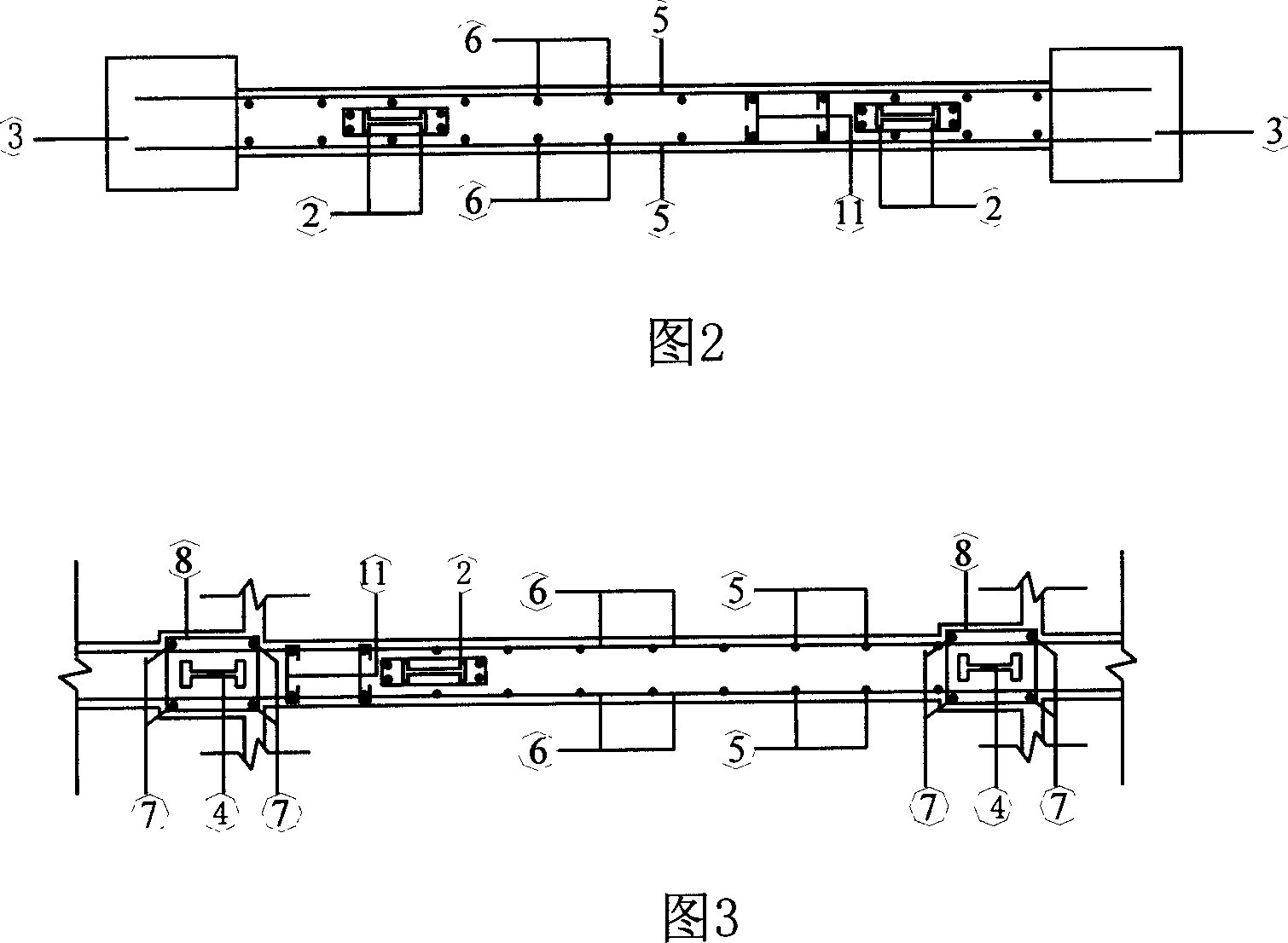

[0033] Figure 1, Figure 2 and Figure 3 show the structural reinforcement of a structural unit of the CFST frame-steel truss-concrete composite shear wall. There is no reinforcement in the frame column 3 of concrete-filled steel tube; the frame beam of the shear wall is a steel beam 4 with longitudinal reinforcement 7 arranged around it, and rectangular stirrups 8 are evenly bound along the longitudinal reinforcement 7 of the beam, and the rectangular stirrups 8 of the frame beam are evenly distributed to Beam end; the reinforcement of the shear wall panel is: the horizontal reinforcement 5 and the vertical reinforcement 6 of the shear wall panel are evenly arranged on both sides of the width direction of the wall panel along the horizontal and vertical directions, and are bound and fixed at the intersection points to form Two pieces of steel mesh, the two ends of the horizontal steel bar 5 and the vertical steel bar 6 are respectively inserted into the steel pipe concrete colum...

Embodiment 2

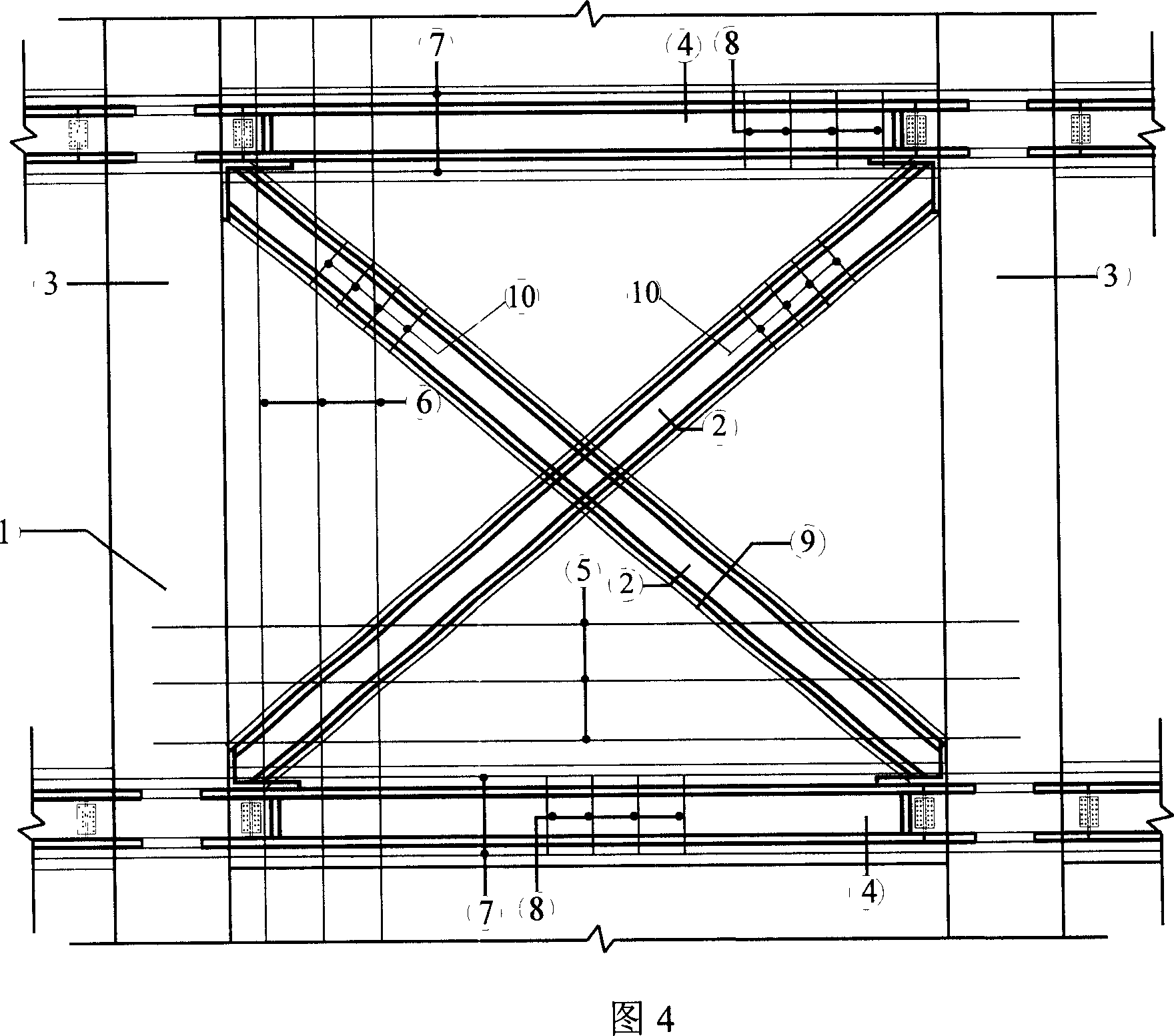

[0044] The second structural form of the CFST frame-steel truss-concrete composite shear wall is shown in Figure 4. The X-shaped hidden steel support 2 and the hidden steel support 9 are arranged on the inside of the two steel meshes of the shear wall panel. It extends into the node between the frame column and the upper frame beam, and is connected with the steel pipe concrete frame column 3 and the upper frame beam medium-sized steel beam 4 . The lower end extends into the node of the frame column and the lower frame beam, and is connected with the steel tube concrete frame column 3 and the lower frame beam medium-sized steel beam 4 . Other aspects are the same as the first form.

Embodiment 3

[0046] The third structural form of the CFST frame-steel truss-concrete composite shear wall is shown in Figure 5. The eight-shaped hidden steel support 2 and the hidden steel support 9 are arranged on the inside of the two steel meshes of the shear wall panel, and the upper end Extending into the upper frame beam to connect with the beam medium-sized steel beam 4, its lower end extends into the node of the frame column and the lower frame beam, and connects with the steel tube concrete frame column 3 and the lower frame beam medium-sized steel beam 4. Other aspects are the same as the first form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com