Method of manufacturing a diffuser master using a blasting agent

a blasting agent and manufacturing method technology, applied in the field of optical elements, can solve the problems of inherently destroying the master diffuser, requiring a sterile environment, and particular methods of creating the diffuser are highly labor-intensive,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

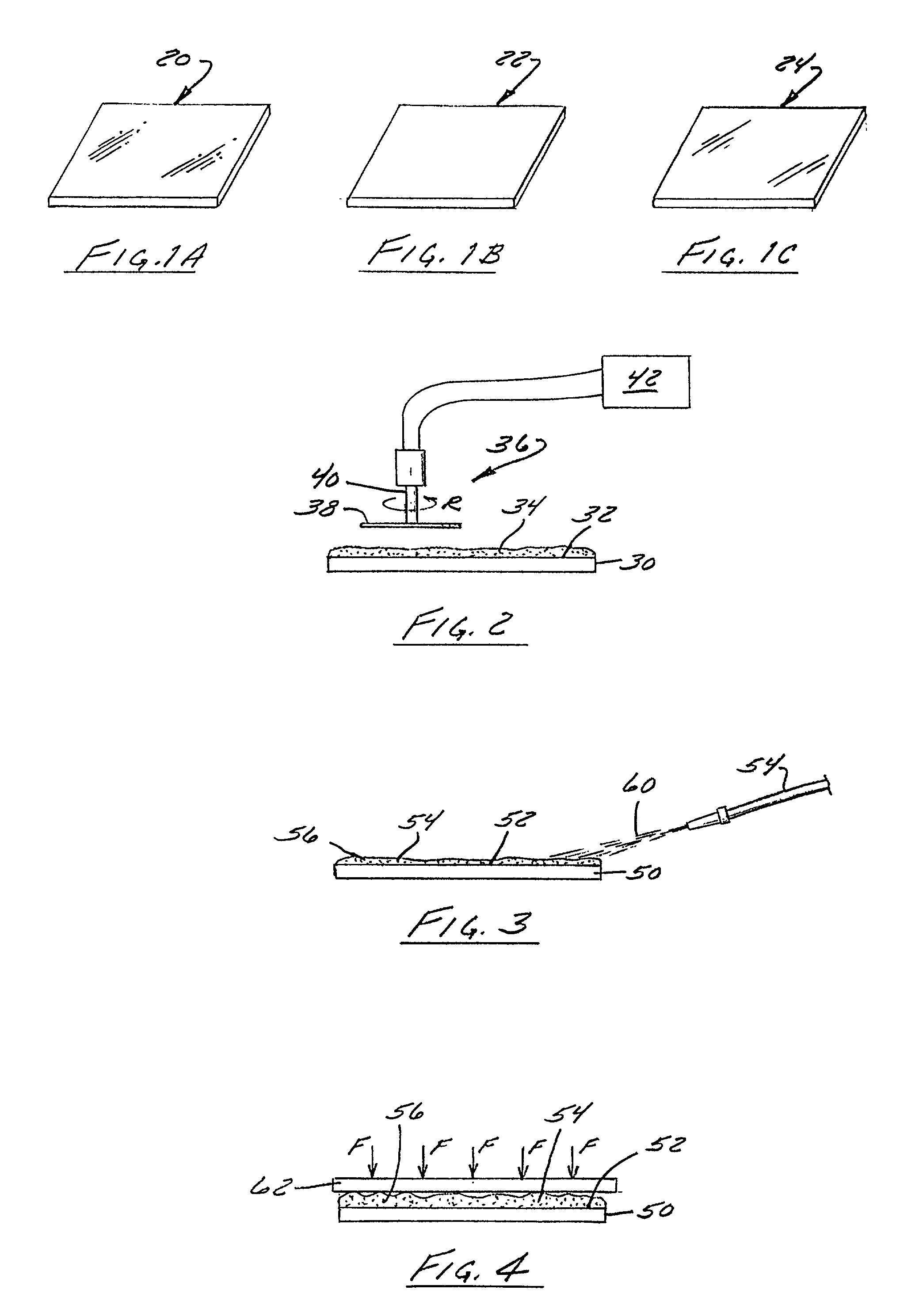

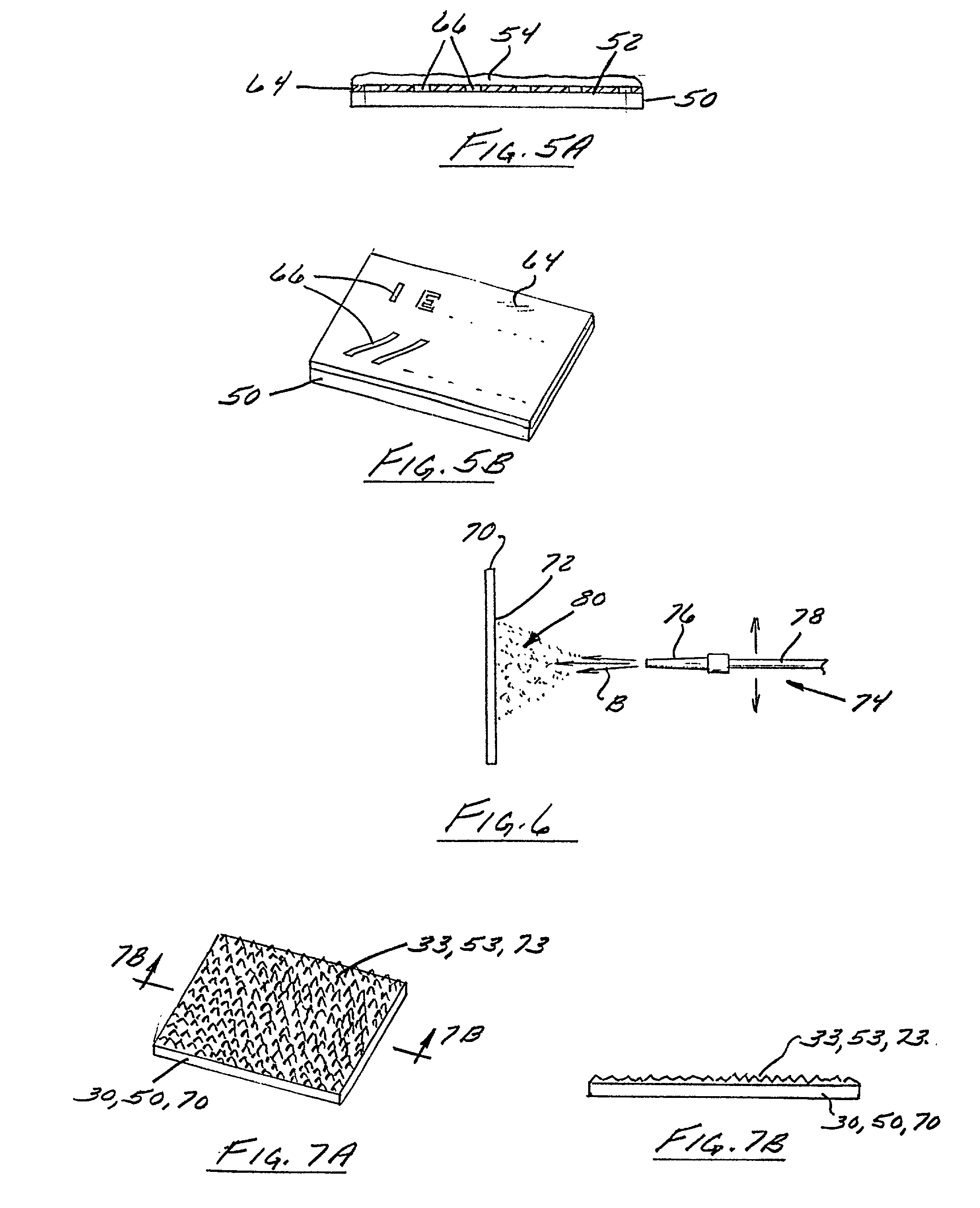

[0035] Referring now to the drawings, FIGS. 1A-1C illustrate several simplified elevational perspective views of diffusers formed by one of the methods of the present invention. The present invention may be utilized to form diffusers from substrate materials such as plastics, glass or metal. The methods are appropriate for forming diffusers from conventional diffuser materials such as epoxy, polycarbonate, polyester, acrylic, nylon, polystyrene, tetrafluoroethylene, polyimide, polyvinyl chloride, polymethyl methacrylate, TPX.TM., ARTON.TM., and other plastic materials but also may be utilized to form diffusers from much more durable materials such as glass and metal for which previous methods were not suitable. Glass materials that can be used include light barium crown, phosphate crown, crown, flint, extralight flint, light flint, fused silicon, and borosilicate. FIG. 1A illustrates a glass diffuser 20 constructed according to one embodiment of the present invention. FIG. 1B illust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com