Low permeability airbag cushionshaving film coatings of extremely low thickness

a low-permeability airbag and film coating technology, which is applied in the direction of envelopes/bags making machinery, paper/cardboard containers, pedestrian/occupant safety arrangements, etc., can solve the problem that the low-permeability airbag must provide a necessarily high leakage time, and achieves a reduction of permeability, high leakage potential, and low add-on amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0039] First, the preferred primer formulation was produced having the composition:

1 Parts Component by weight Desmoderm .RTM. 43195 (Bayer Corporation, polyurethane resin) 25 grams Dimethylformamide (Aldrich, solvent) 75 grams Desmodur .RTM. CB-75N (Bayer, polyisocyanate adhesion 4 grams promoter)

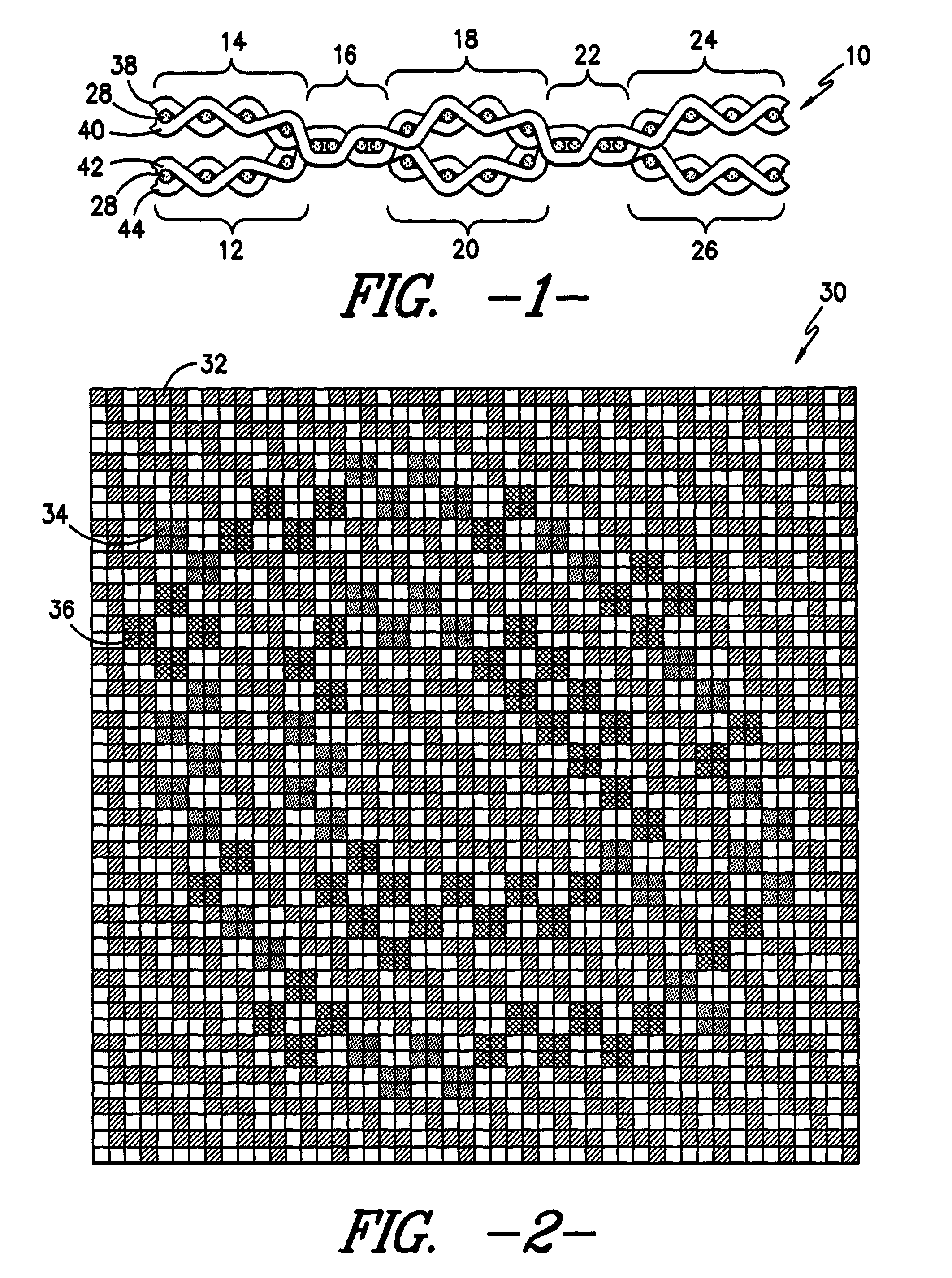

[0040] This formulation was applied to both sides of a 2.5 liter size Jacquard woven nylon airbag (of 440 denier fibers), made in accordance with FIGS. 1 and 2, below. The primer was dried at about 160.degree. C. for about 2 minutes to obtain a dry coating weight of about 0.25 ounces per square yard on each side. Subsequently, a 2 mil thick polyurethane film (Dureflex.TM. PT9400) was then laminated on both sides of the primer coated airbag utilizing a hotpress providing about 80 psi pressure at about 188.degree. C. with a residence time of about 1 minute. The total polyurethane film add-on weight on each side of the airbag was about 2.2 ounces per square yard. The airbag was then rapidly i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com