Jacket tube for a drilling and anchoring device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

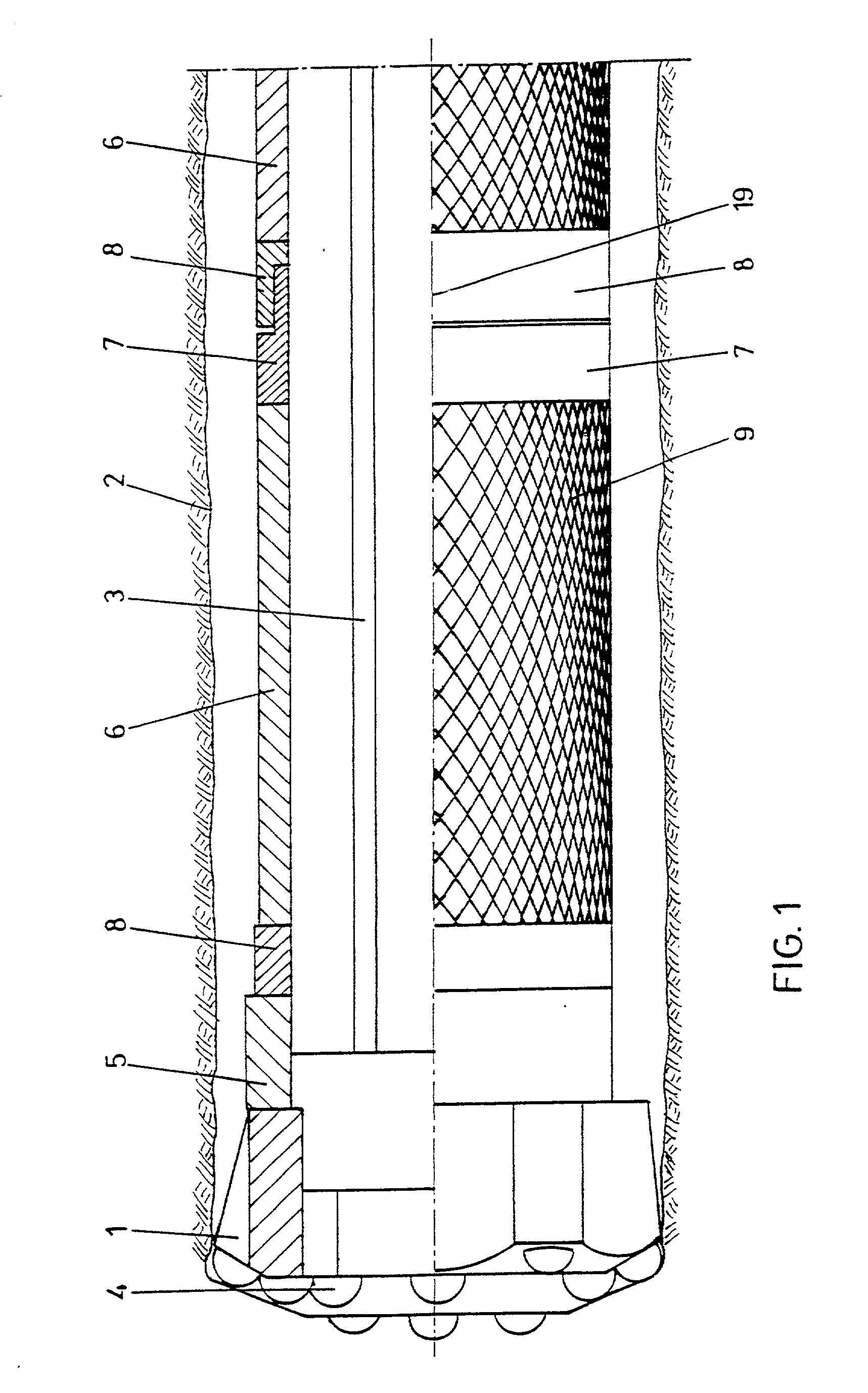

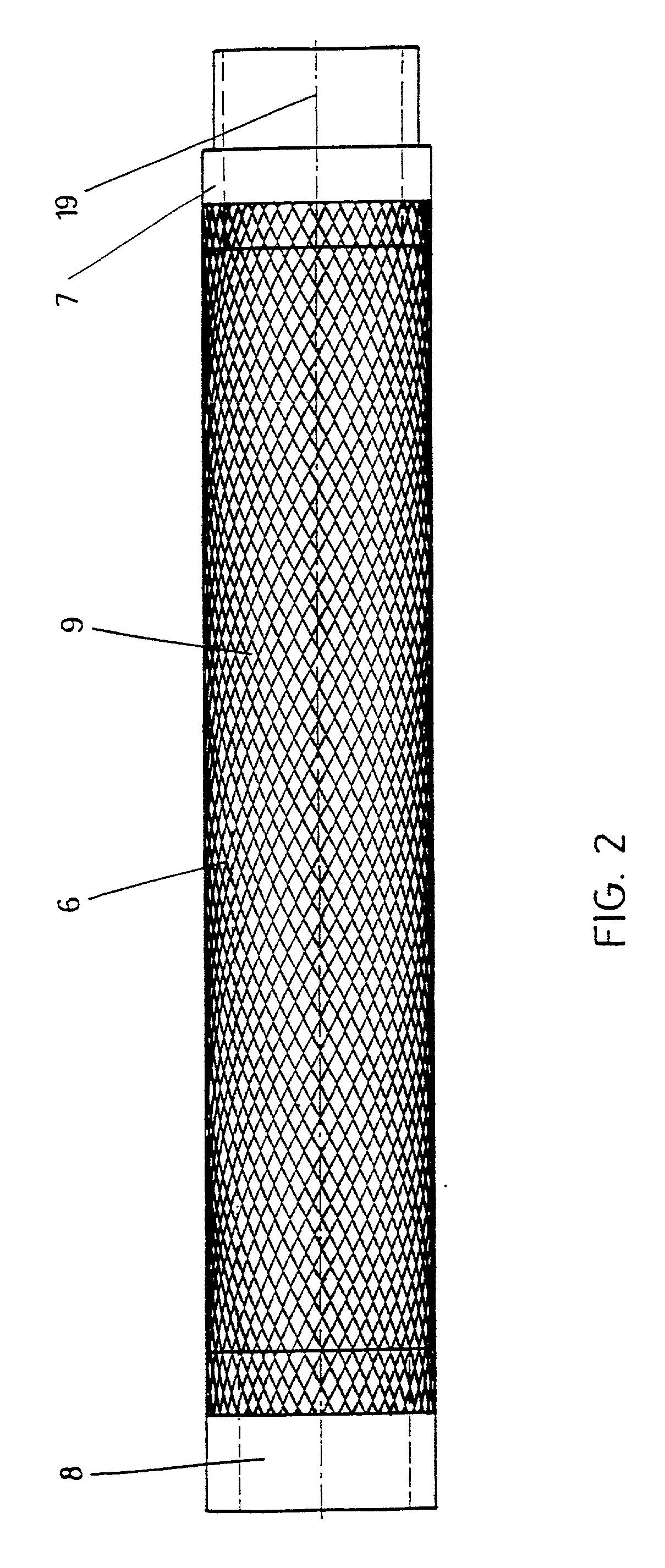

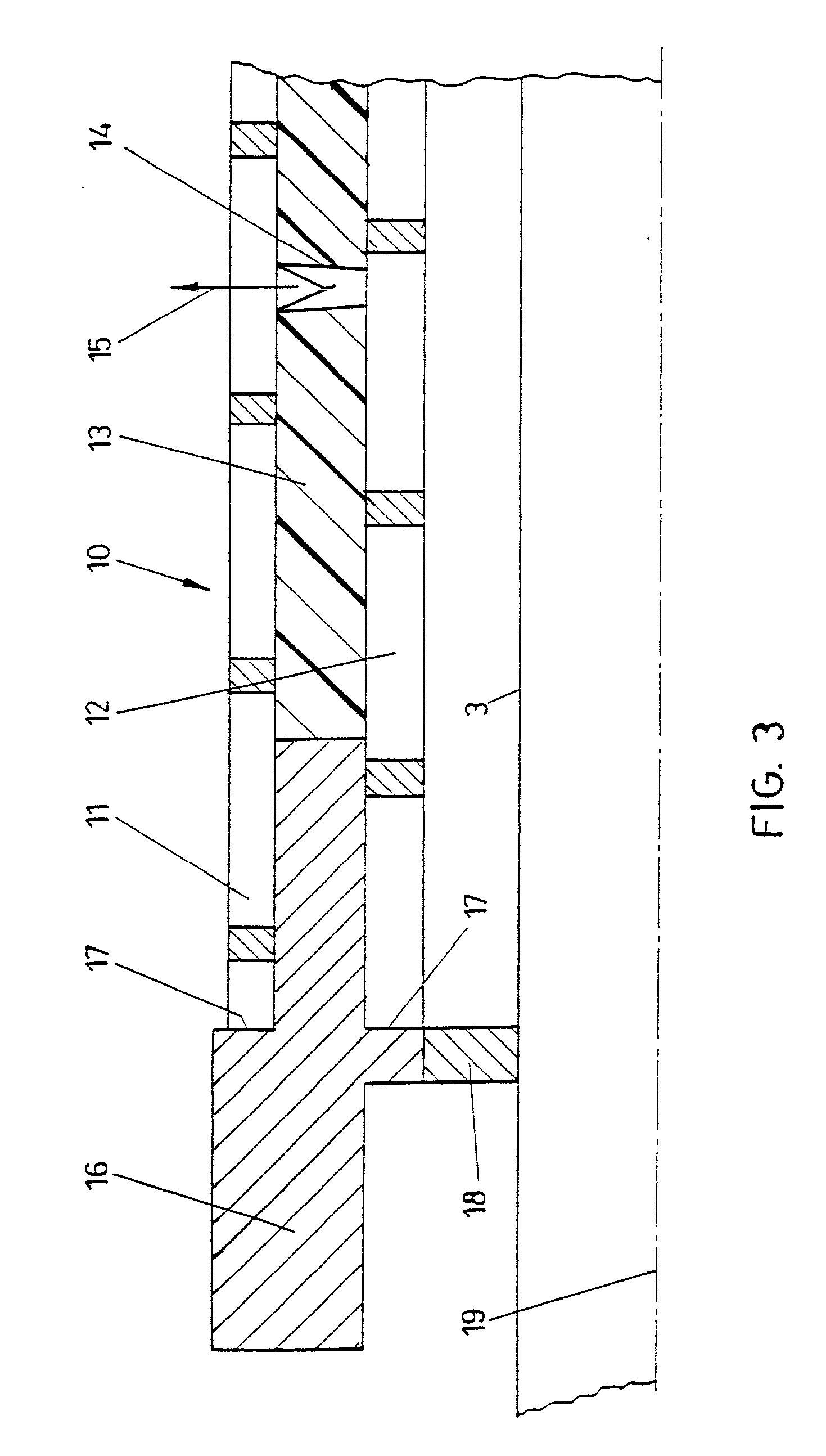

[0018] FIG. 1 schematically depicts a drill bit 1 for forming a drill hole whose outer contour is indicated by 2, a schematically indicated drill rod assembly 3 being used for actuating the drill bit 1. Immediately with the drill bit 1 on the side facing away from the drilling elements 4, or the impact shoe 5 of the drill bit 1, is provided a jacket tube 6, wherein the jacket tube 6, as is particularly clearly apparent from FIG. 2, is comprised of expanded metal elements which, on their end regions, are each designed with sleeve elements 7 and 8 for connection with the drill bit 1, or impact shoe 5, as well as adjacent jacket tube elements 6. The sleeve elements 7, 8 may be designed with a view to obtaining an appropriate plug-in or screw connection in order to enable the appropriate extension of the jacket tube 6 similar to the extension of the drill rod assembly 3, in particular in case of a large-dimensional drill hole.

[0019] Such a jacket tube or expanded metal element 6 is clea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap