Machine to line containers with film

a machine and film technology, applied in the field of machine to line containers with film, can solve the problems of increasing the cost, increasing the space between the liner and the outer container, and the pouch does not have enough rigidity to be self-supporting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

claim 1:

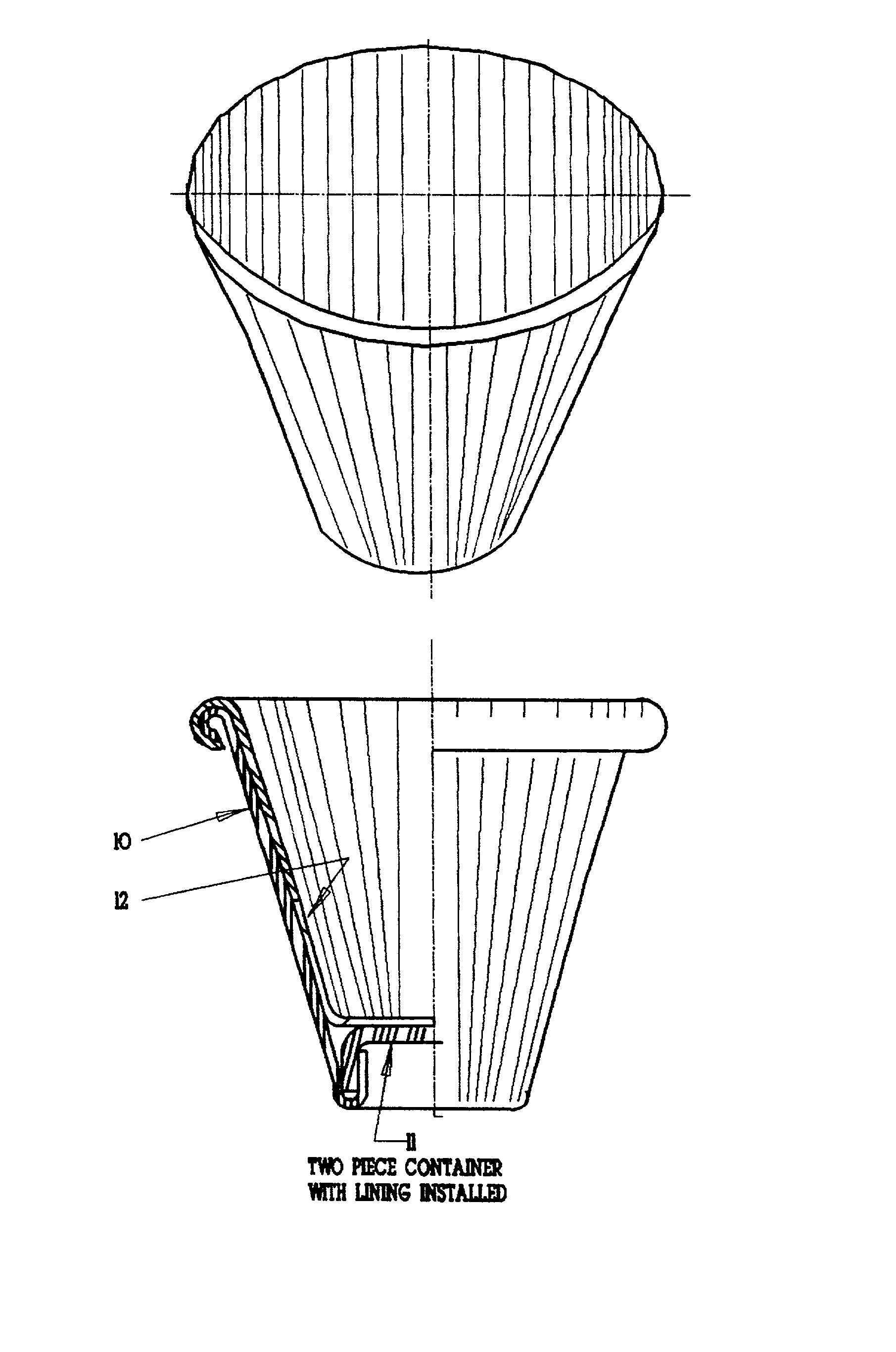

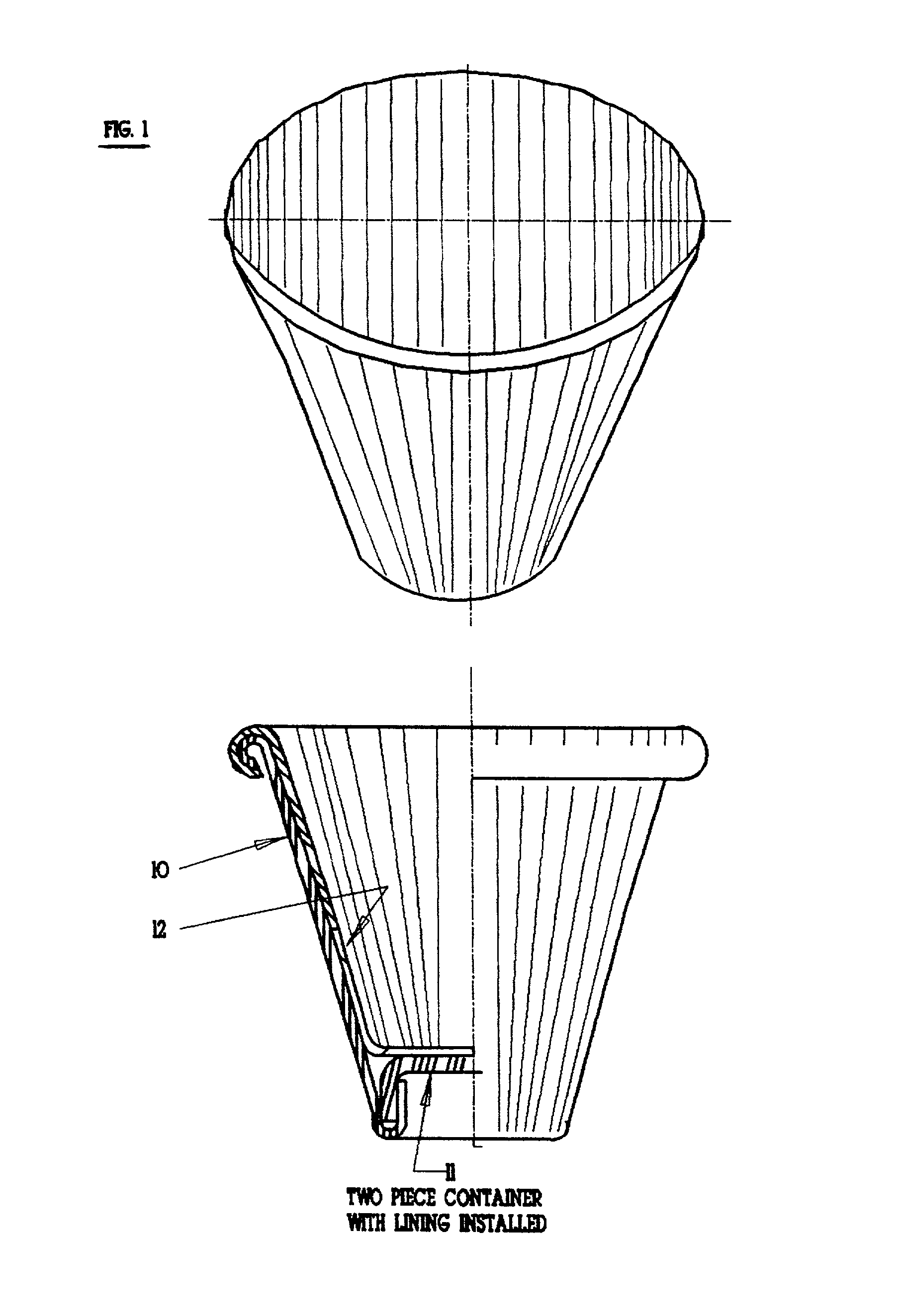

[0029] FIG. 1, FIG. 3, and FIG. 4 of the drawings discloses pre formed, two (2) piece containers, designated by reference numbers 10, the outer shell and 11, the unitary bottom wall on one end thereof with an opposite open end. The inner liner 12 discloses film whose shape conforms to the outer shell 10 and bottom wall 11, and is hermetically sealed to the same. The outer shell and inner liner may be formed by a variety of materials

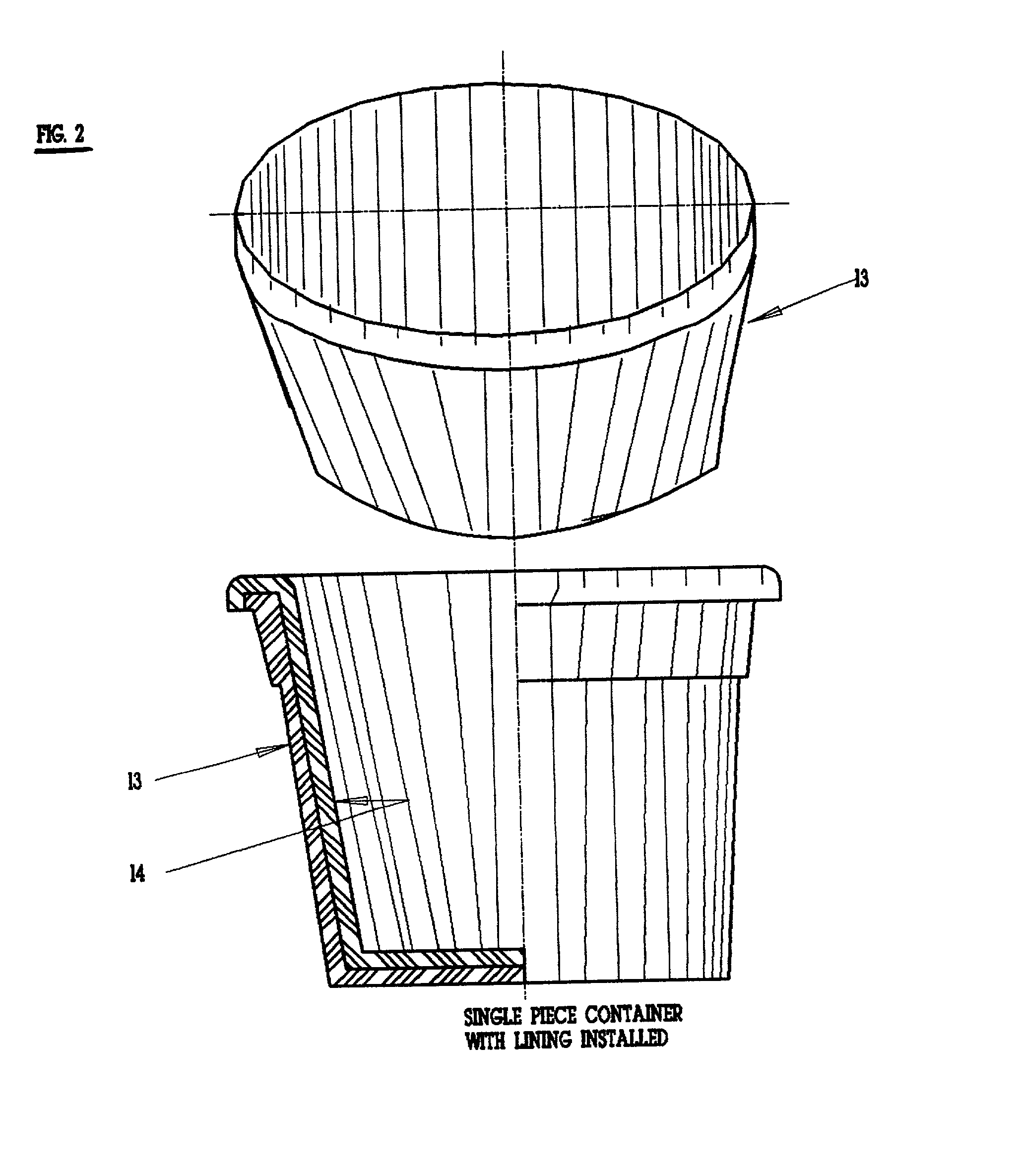

[0030] FIG. 2 of the drawings discloses a single piece formed container designated by number 13 which includes both the side wall and unitary bottom wall on one end thereof with an opposite open end. The inner liner 14 discloses a film whose shape conforms to the outer shell 13 and the bottom wall, and is hermetically sealed to the same. The outer shell and inner and outer shell may be formed by a variety of materials.

[0031] Preface for Data used in Claim 2:

[0032] We furnish drawing number MD-1600, sheet 1 for your information.Our suppliers have p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com