Drawer slide socket and method

a technology for sliding sockets and drawers, applied in drawers, furniture parts, domestic applications, etc., can solve problems such as difficulty in leveling or horizontal installation of other self-adjusting brackets, subsequent operation problems during drawer use,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

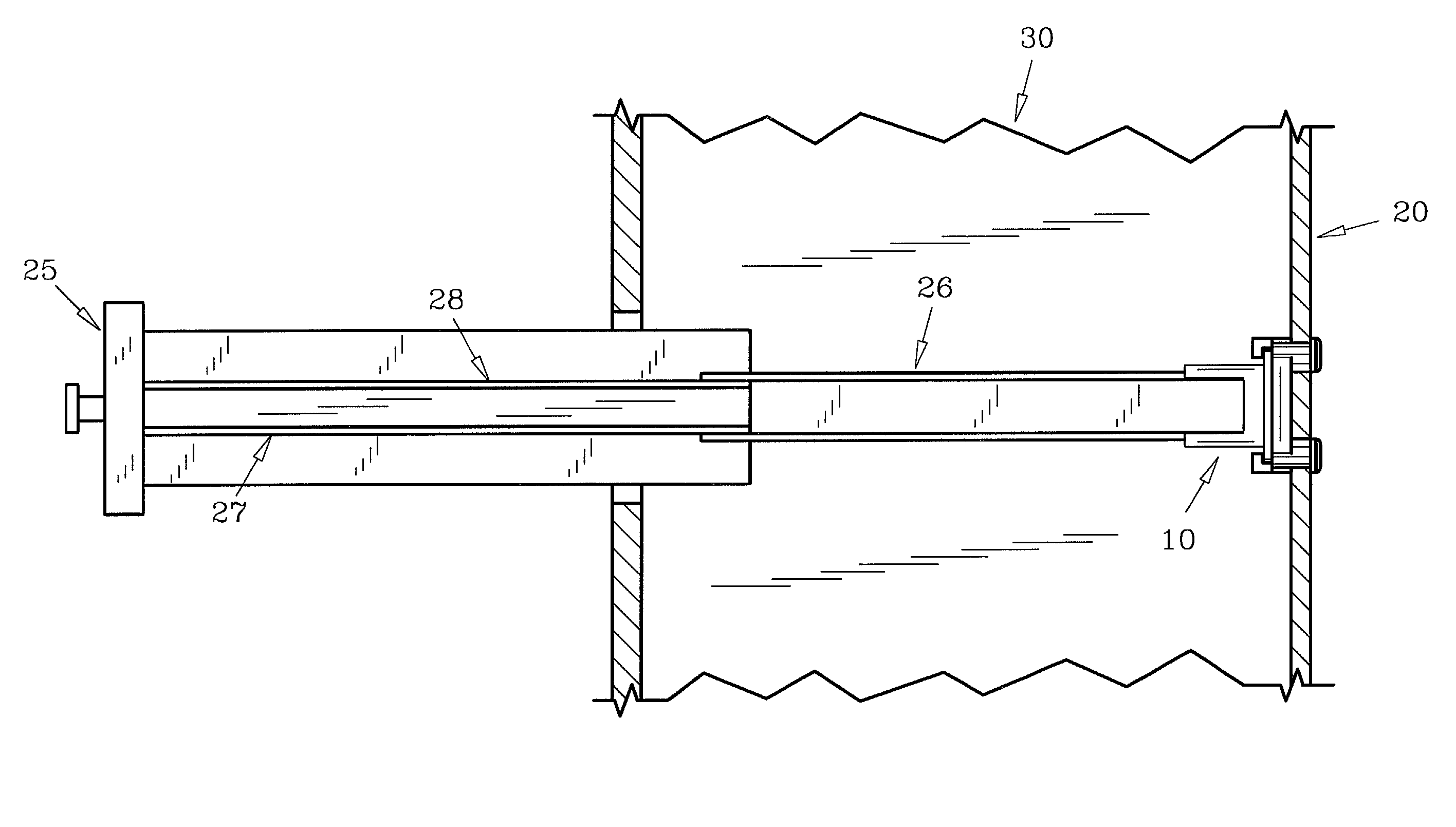

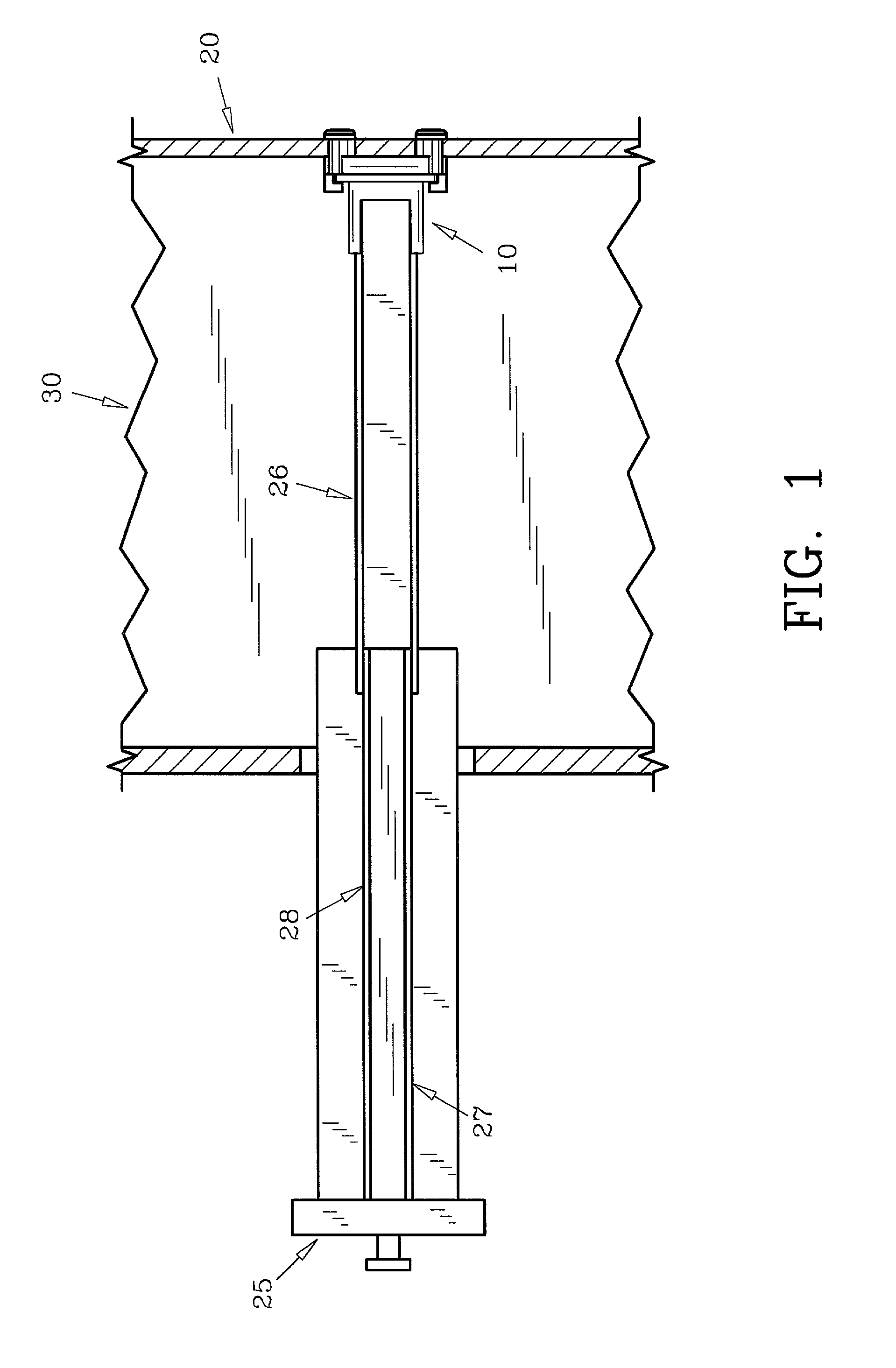

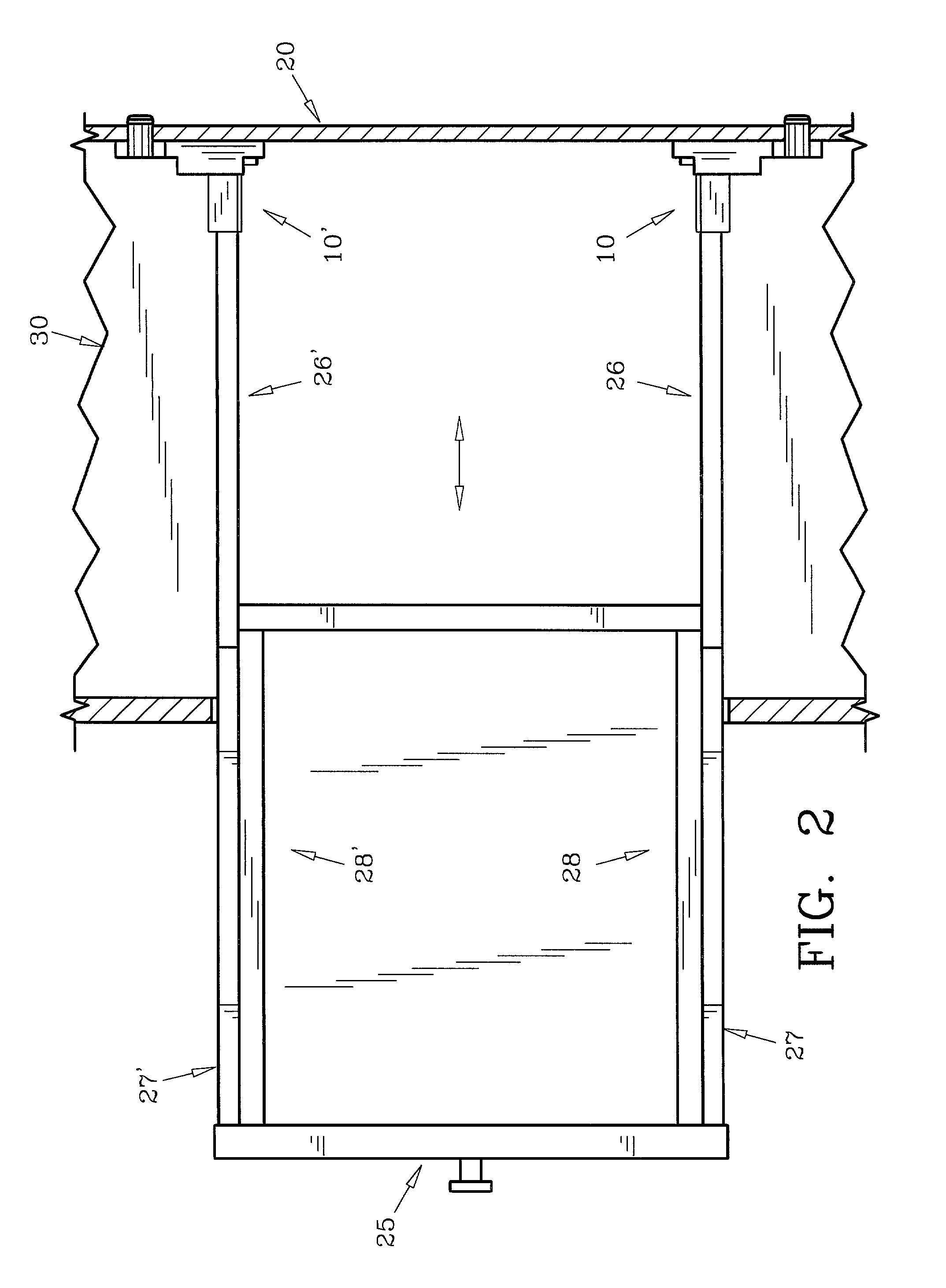

[0023] For a better understanding of the invention and it operation, turning now to the drawings, FIG. 1 shows a schematic cross-sectional view of a typical installation of preferred drawer slide socket 10 mounted on back wall 20 of cabinet 30. Cabinet 30 may be, for example, a kitchen cabinet and have one or more drawers 25 as is standard in the industry. Drawer slide socket 10 receives the terminal end of c-shaped cabinet section 26 of drawer slide 28. As would be understood, c-shaped drawer section 27 of telescopic drawer slide 28 is affixed to drawer 25 by screws or other fasteners (not shown) and is movable within cabinet section 26 as is usual in the trade. Drawer slide 28 is formed from metal and is one of a pair of side drawer slides used with drawer 25, the other drawer slide mounted on the opposite side as seen in FIG. 2. As would be understood, drawer slide socket 10 is used in pairs, but is generally described herein in singular fashion.

[0024] For a view of drawer slides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com