Light emitting diodes with spreading and improving light emitting area

a light emitting diode and spreading current technology, applied in the field of light emitting diodes, can solve the problems of insufficient conductivity of the p-type gan, the difficulty of making p-type ohmic contacts on and spreading current in the p-type gan layer, and the inability to achieve high-conductivity p-type gans, so as to improve the light emitting area, spread current, and enhance the effect of light emitting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

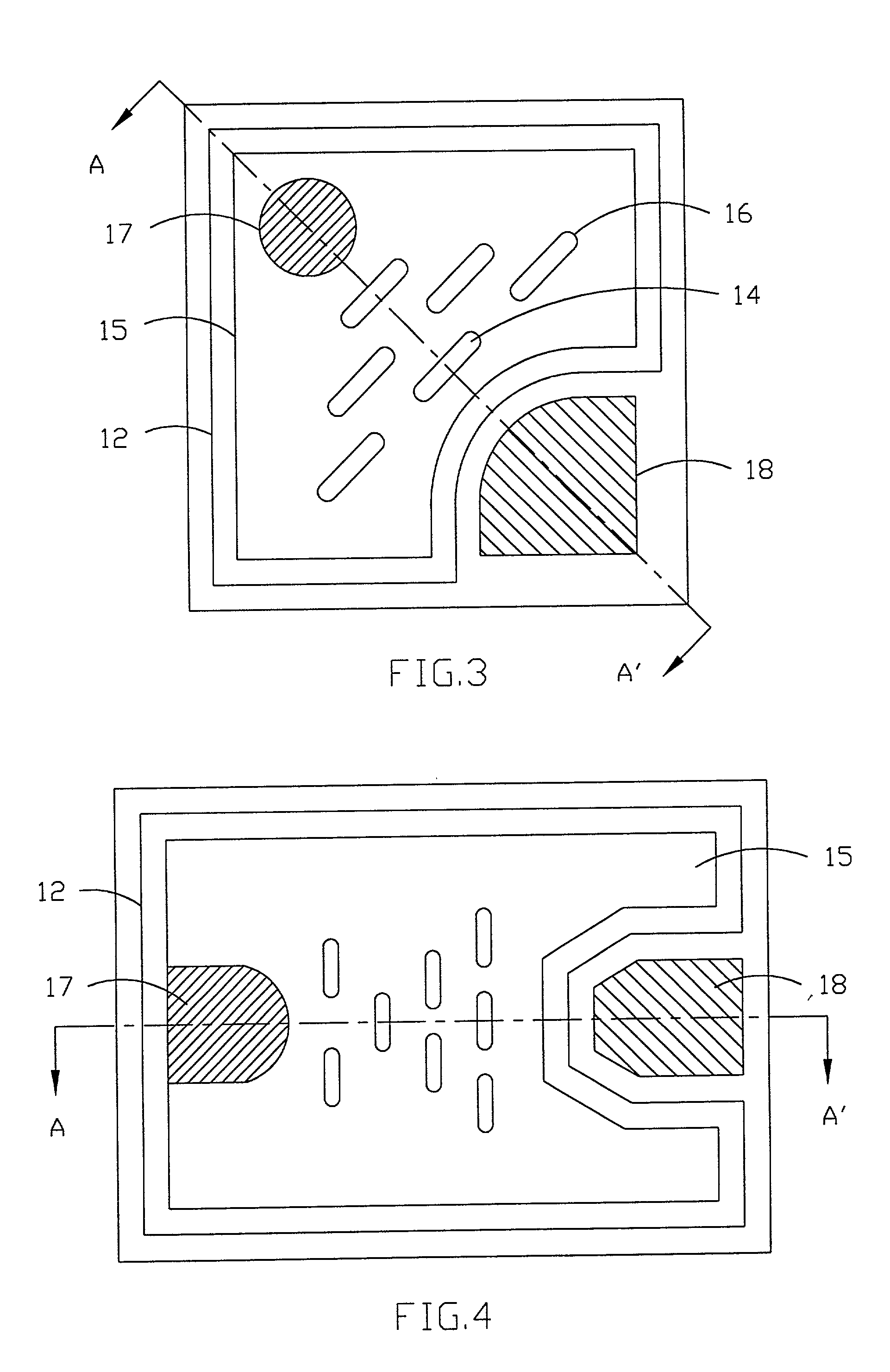

second embodiment

[0031] In the second embodiment, a transparent contact 25, a p-type contact 27, and an n-type contact 28 are on an n-GaN structure 22. They are arranged in such way that the distance from any point of the p-type contact 27 to the n-type contact 28 is the shortest and kept same for each path. The p-type contact 27 has a quarter-circle shape, and the transparent contact 25 has a fan shape that has a same center of the circle as that of the p-type contact 27. The radial distance of spreaded current is all the same from the p-type contact 27 to the n-type contact 28 through the transparent contact 25.

[0032] Depicted in FIG. 7 is another one design of the shapes and arrangements for a p-type contact 37, an n-type contact 38, and a transparent contact 35 on a mesa structure 32 which is on an n-GaN structure 33. The p-type contact 37 and the n-type contact 38 are arranged at the opposite sides rather than the opposite corners. The shapes of the p-type contact 37 and the n-type contact 38 a...

first embodiment

[0033] Again, the current spreading and efficient usage of the lightemitting area is further improved with more symmetrical contact configuration, shown in FIG. 8. In the embodiment, the epi-layer structure is the same as that of the first embodiment, while the shapes of the mesa and contacts are different. A ring-shape n-type contact 48 is around the device and on the n-type GaN-based layer 42, both are located at the bottom of the mesa. A p-type transparent contact 45 is on a p-type GaN-based layer 44 and the p-type GaN-based layer 44 is at the top of the mesa. For spreading the current, a p-type contact 47 is positioned at or near the center of the mesa, and n-type contact 48 has a contact pad and a conduction ring. The shapes and positions for both contacts (47 and 48) provide all current distances between the contacts equal or nearly equal all the way around the mesa. Therefore, the device exhibit good current spreading and high area utility. The shape of the p-type contact 47 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com