Backup power supply

a power supply and back-up technology, applied in emergency power supply arrangements, secondary cell servicing/maintenance, transportation and packaging, etc., can solve the problems of low power conversion efficiency, high price, and large volume of power units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

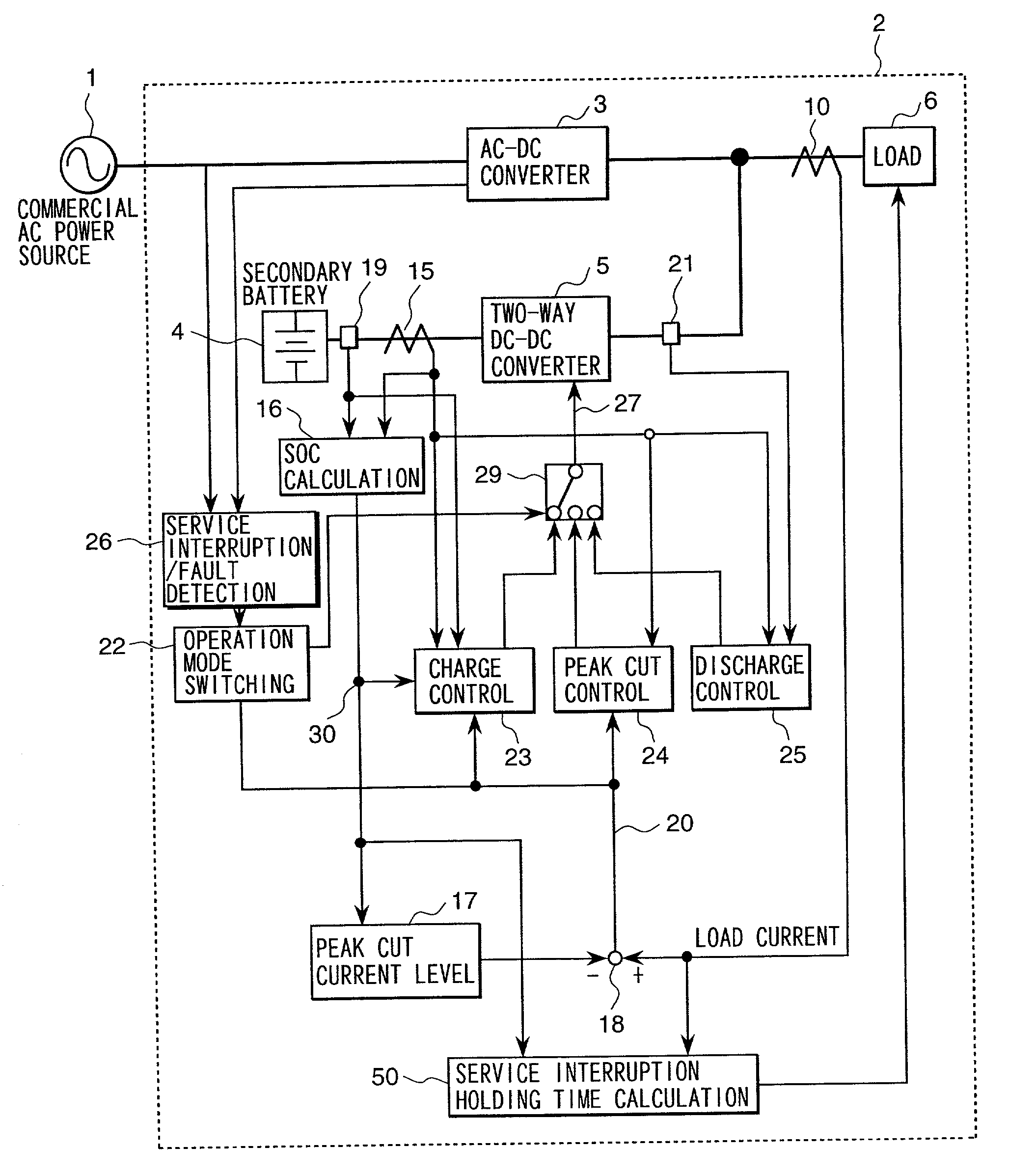

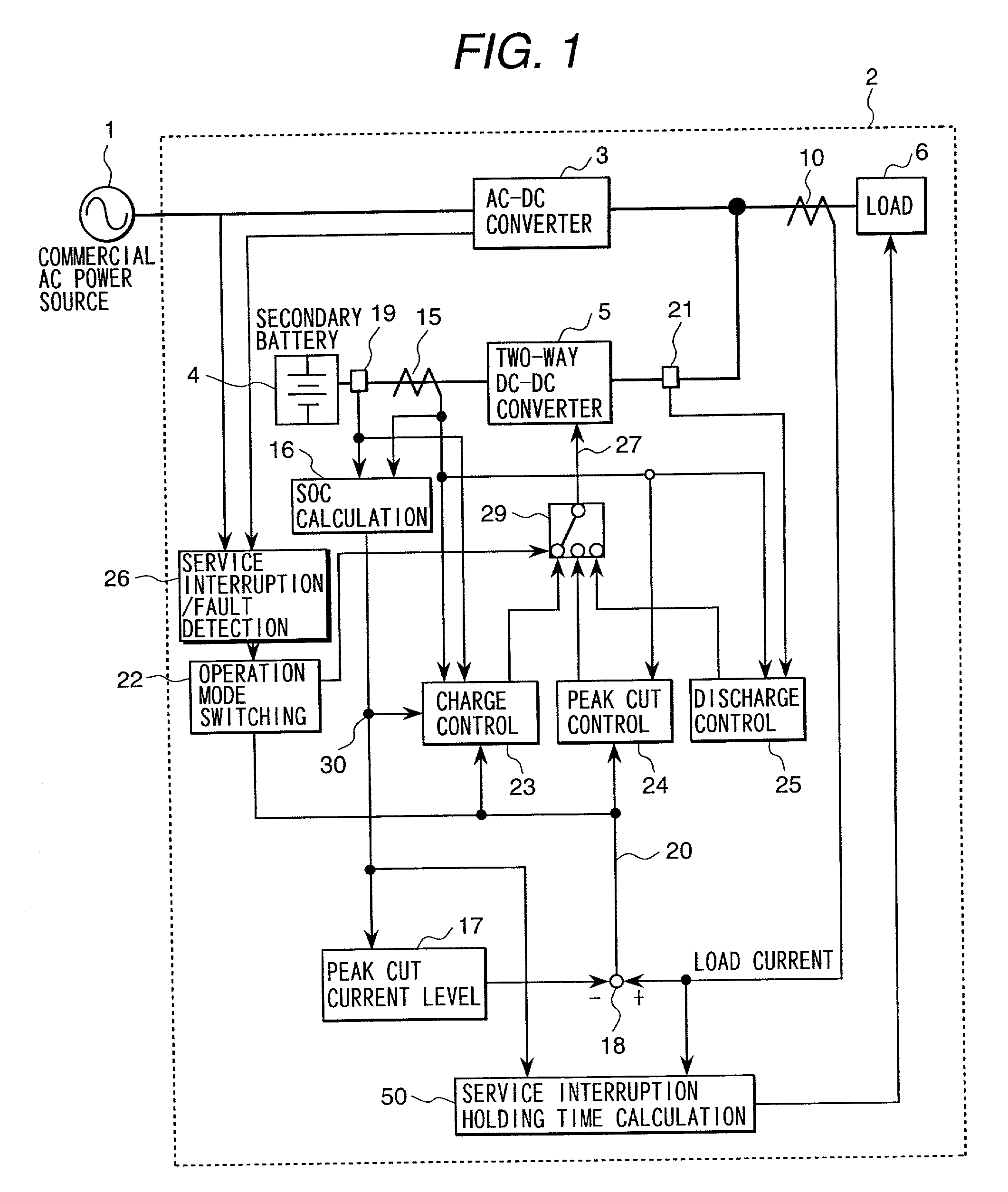

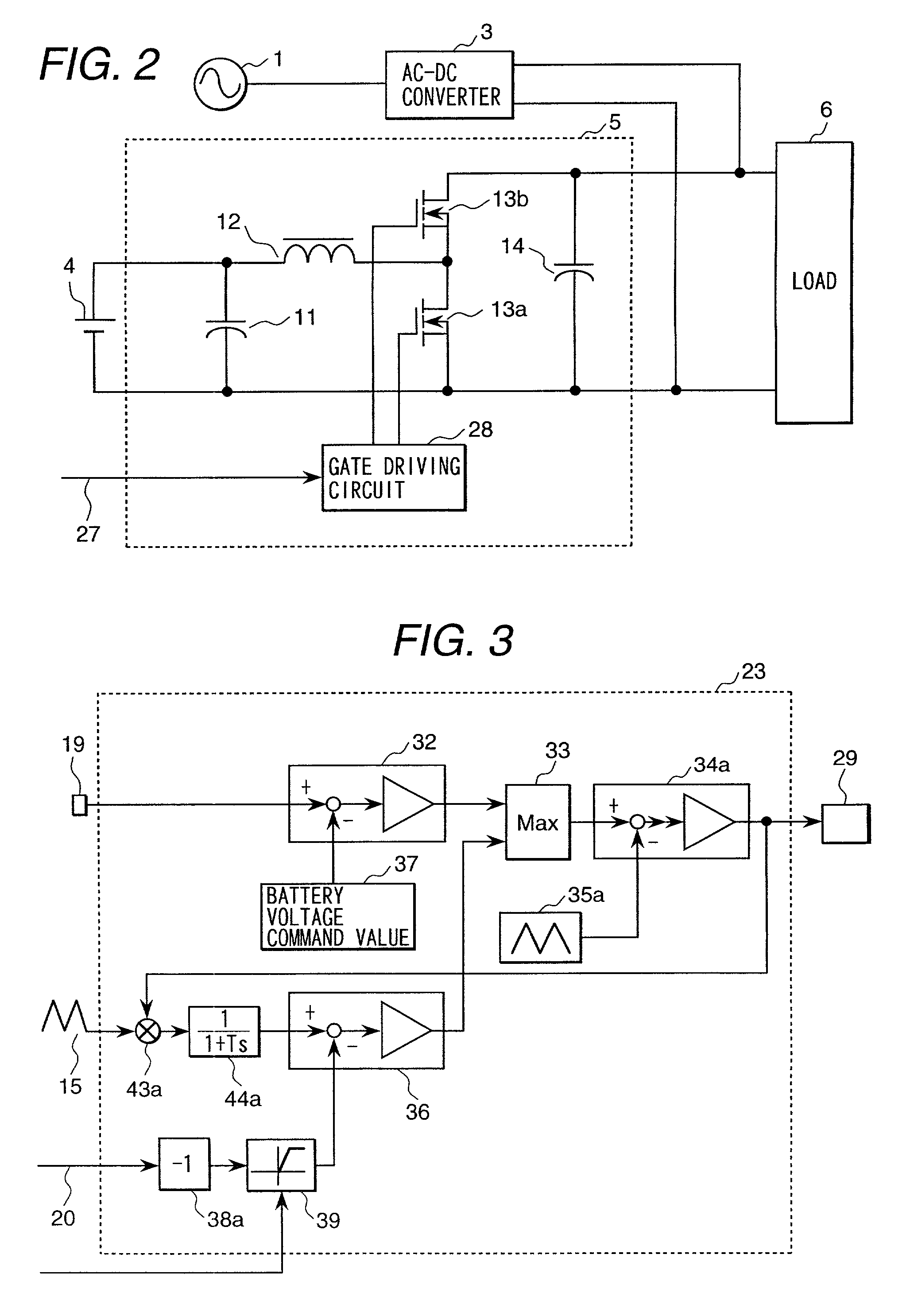

[0031] the present invention will be explained by referring to FIGS. 1 to 8. FIG. 1 is a block diagram showing an embodiment of the present invention. In FIG. 1, an information processor 2 internally has an AC-DC converter 3, a secondary battery 4, a two-way DC-DC converter 5, a load 6, a load current detector 10, a battery current detector 15, an SOC calculation circuit 16, a peak cut current level setting unit 17, a subtracter 18, a battery voltage detection means 19, an output voltage detection means 21, an operation mode switching circuit 22, a charge control circuit 23, a peak cut control circuit 24, a discharge control circuit 25, a service interruption / fault detection circuit 26, and a service interruption holding time calculation circuit 50.

[0032] A commercial AC power supply 1 is a commercial AC power supply of 100 V or 200 V and connected to the AC-DC converter 3 and the service interruption / fault detection circuit 26 installed in the information processor 2. A fault signa...

second embodiment

[0068] Next, the present invention will be explained. In FIG. 9, the same numerals are assigned to the same components as those shown in FIG. 1. Additionally, a memory 48 and a load current pattern setting unit 49 are provided. The connection configuration of the components other than the aforementioned shown in FIG. 9 is the same as that shown in FIG. 1. The memory 48 is connected to the load current detector 10 and the load current pattern setting unit 49 is connected to the memory 48. The output of the load current pattern setting unit 49 is input to the peak cut current level setting unit 17.

[0069] Next, the operation will be explained. The variation of the load current is detected by the load current detector 10 and recorded in the memory 48. For example, one day is divided every a fixed period such as every one minute or one second and load currents are sampled and stored at a predetermined address of the memory 48 as mean value data thereof. At the same time on the next day, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com